Mining equipment and method for unmanned working face in thin coal seam of short-distance high-gas coal seam group

A technology for working face and coal seam group, applied in surface mining, earth-moving drilling, underground mining, etc., can solve the problems of low production efficiency, high labor intensity, difficult operation, etc., and achieve a high degree of automation, high safety and reliability. , the effect of personnel safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

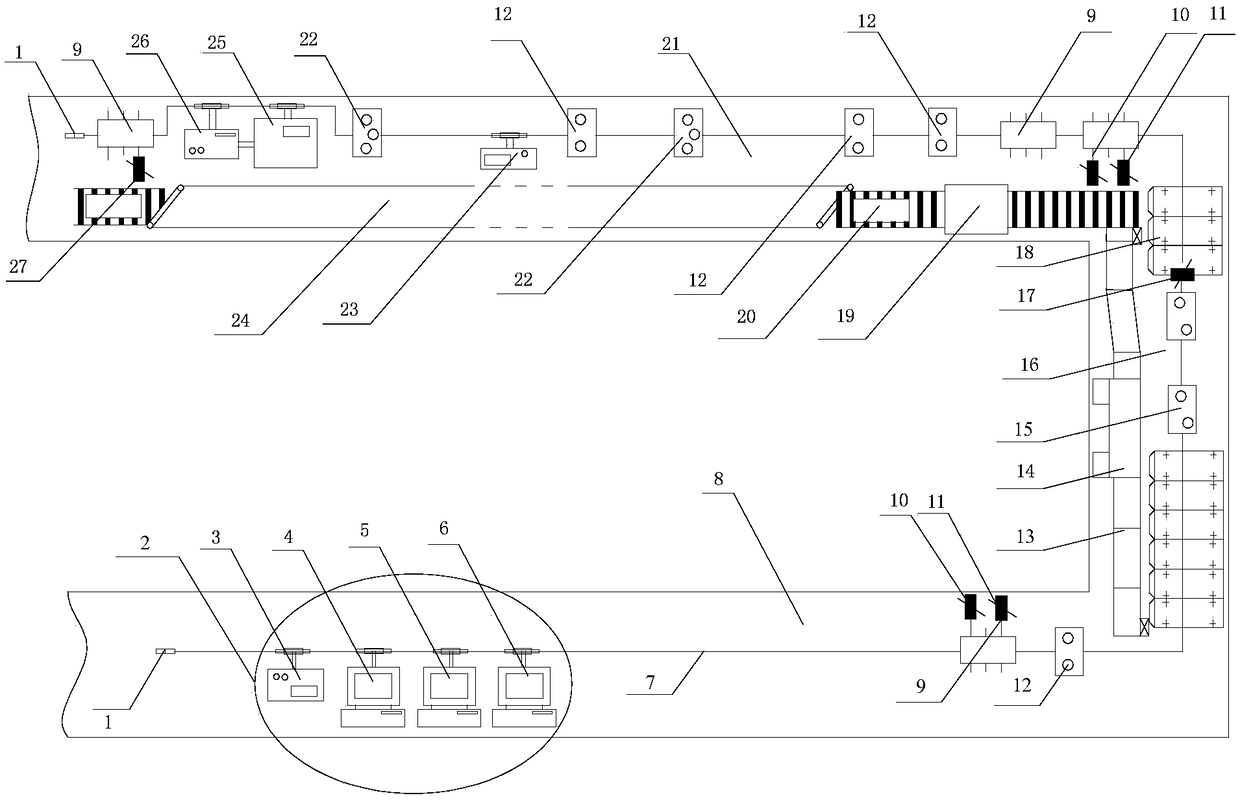

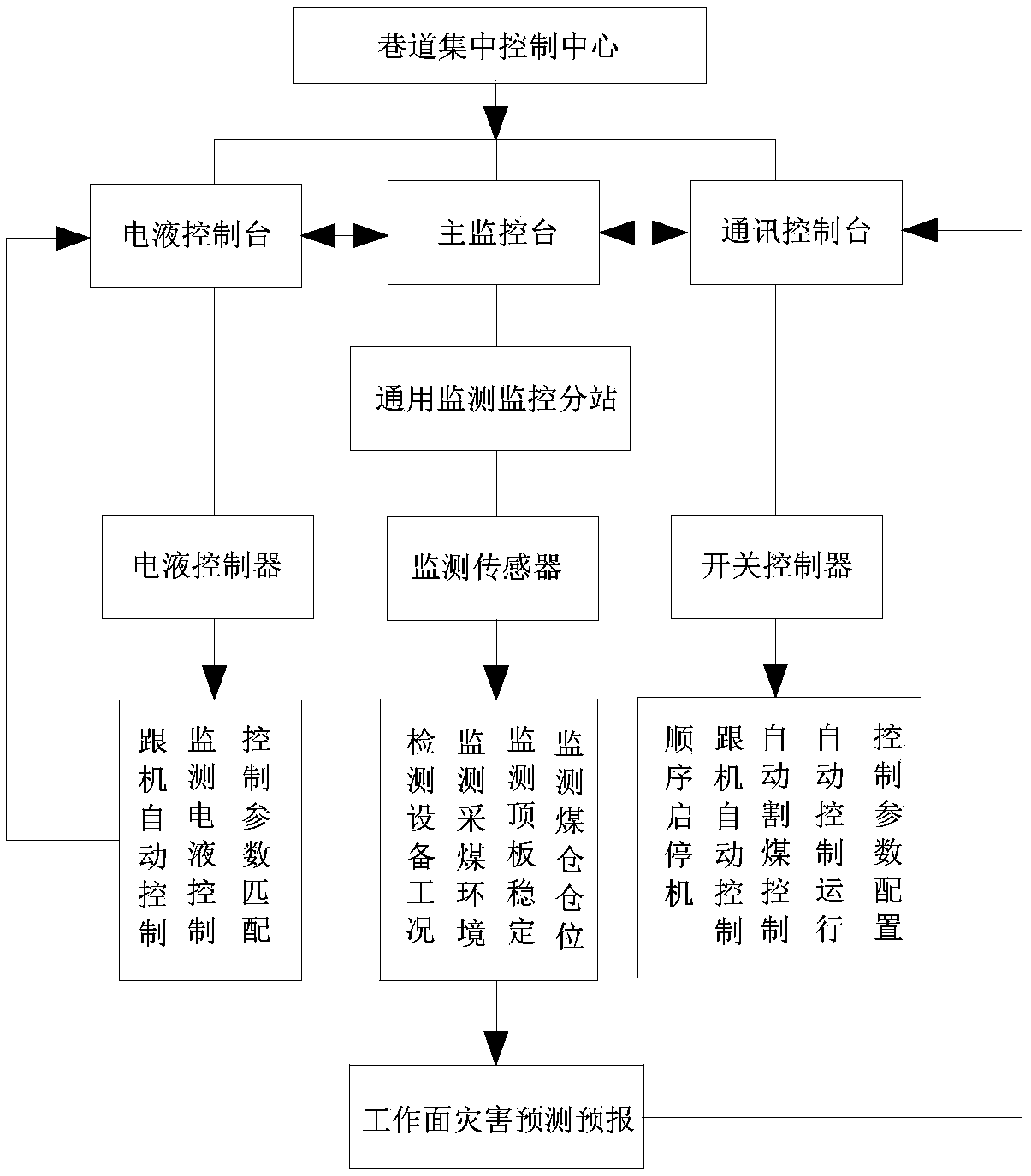

[0059] Embodiment 1: in combination with figure 1 The specific implementation steps of the present invention are described:

[0060] 1. Arrange the mining face along the direction of the thin coal seam in the predetermined mining area, excavate the entry wind entry 8 and the transportation entry 21, lay the rail mine car in the entry entry entry, arrange the crusher 19, the transfer machine 20, Belt conveyor 24, pumping station 25, mobile substation 26, scraper conveyor 13, low-body roller shearer 14, hydraulic support 18 are installed in the unmanned working surface 16;

[0061] 2. Arrange a centralized control center 2 in the air inlet level road, install a mining intrinsically safe power supply box 3 to supply power for the centralized control system; install an electro-hydraulic console 4, a main monitoring console 5 and a communication console 6;

[0062] 3. The ring bus 7 is led out from the centralized control center 2 of the air inlet lane, which is used to connect va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com