Overhead fuel gas heat preservation anti-freezing pipeline and using method thereof

A gas and pipeline technology, which is applied in the direction of pipeline support, pipeline heating/cooling, pipe components, etc., can solve the problems of energy waste, poor antifreeze effect, etc., and achieve the effect of improving service life and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

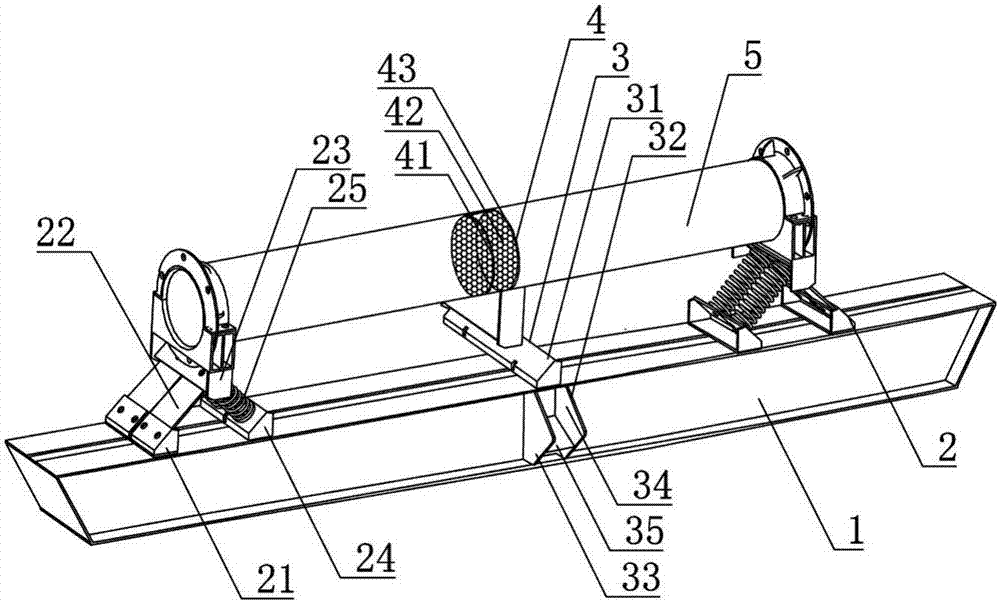

[0038] like figure 1As shown, the overhead gas heat preservation and antifreeze pipeline includes an installation tank 1, a support structure 2, a water collection structure 3, a separation structure 4, and a delivery pipeline 5. There are support structures 2 on both sides of the upper surface of the installation tank 1, and the support structure 2 is erected Conveying pipeline 5, the middle inner wall of conveying pipeline 5 is provided with separation structure 4, and water collection structure 3 communicates with separation structure 4 and conveying pipeline 5 respectively, and separation structure 4 comprises front support frame 41, hollow fiber membrane 42, rear support frame 43, The fiber membrane 42 is radially provided with a drainage channel (not shown in the figure), and the lower wall of the drainage channel is hollowed out.

[0039] It should be noted that the drainage channel is not drawn separately in the figure, because the purpose of this technical solution is...

Embodiment 2

[0046] Such as figure 1 As shown, the overhead gas heat preservation and antifreeze pipeline includes an installation tank 1, a support structure 2, a water collection structure 3, a separation structure 4, and a delivery pipeline 5. There are support structures 2 on both sides of the upper surface of the installation tank 1, and the support structure 2 is erected Conveying pipeline 5, the middle inner wall of conveying pipeline 5 is provided with separation structure 4, and water collection structure 3 communicates with separation structure 4 and conveying pipeline 5 respectively, and separation structure 4 comprises front support frame 41, hollow fiber membrane 42, rear support frame 43, The fiber membrane 42 is radially provided with a drainage channel (not shown in the figure), and the lower wall of the drainage channel is hollowed out.

[0047] It should be noted that the drainage channel is not drawn separately in the figure, because the purpose of this technical solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com