Acoustic levitation multi-droplet evaporation and combustion experiment device and method

A droplet evaporation and experimental device technology, applied in the investigation phase/state change and other directions, can solve the problem of inability to study the evaporation and combustion characteristics of small free-form multi-droplets, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

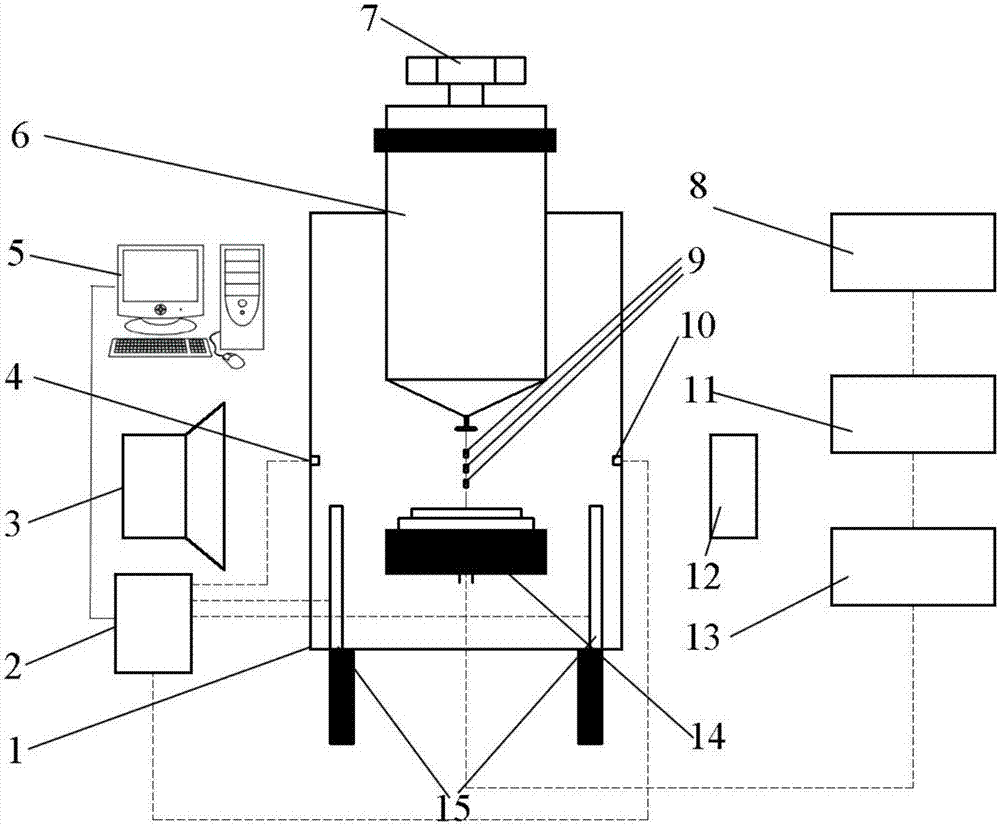

[0020] A further description of the acoustic suspension multi-droplet evaporation and combustion device of the present invention is given below in conjunction with the embodiments and accompanying drawings:

[0021] An acoustic levitation multi-droplet evaporation and combustion device of the present invention includes an acoustic levitation device, an evaporation and combustion chamber 1 , an acoustic levitation control system, and a control unit 2 . The acoustic levitation device includes a frequency converter 6, a reflector 14, and an alignment tool 7 between the frequency converter and the reflector; the evaporation and combustion chamber includes an evaporation combustion chamber body 1, a plurality of evenly arranged stainless steel heating rods 15, an observation window and a temperature sensor 4 and 10; the acoustic levitation control system includes a signal generator 8, a power amplifier 11 and a power meter 13; the control unit is respectively connected to the acoust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com