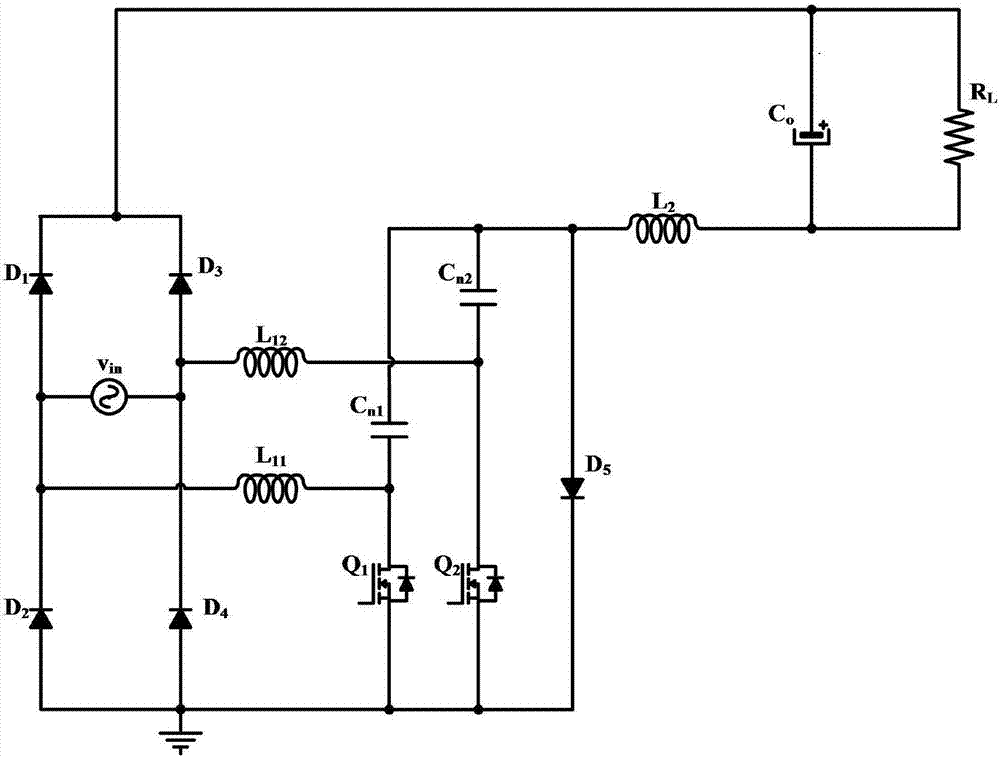

Bridgeless boost type CUK PFC circuit

A step-up type, circuit technology, applied in the direction of electrical components, high-efficiency power electronic conversion, sustainable manufacturing/processing, etc., can solve the problems of the rectifier bridge on-state loss, the improvement of the efficiency of the whole machine, etc., to reduce the conduction The effect of loss and small number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

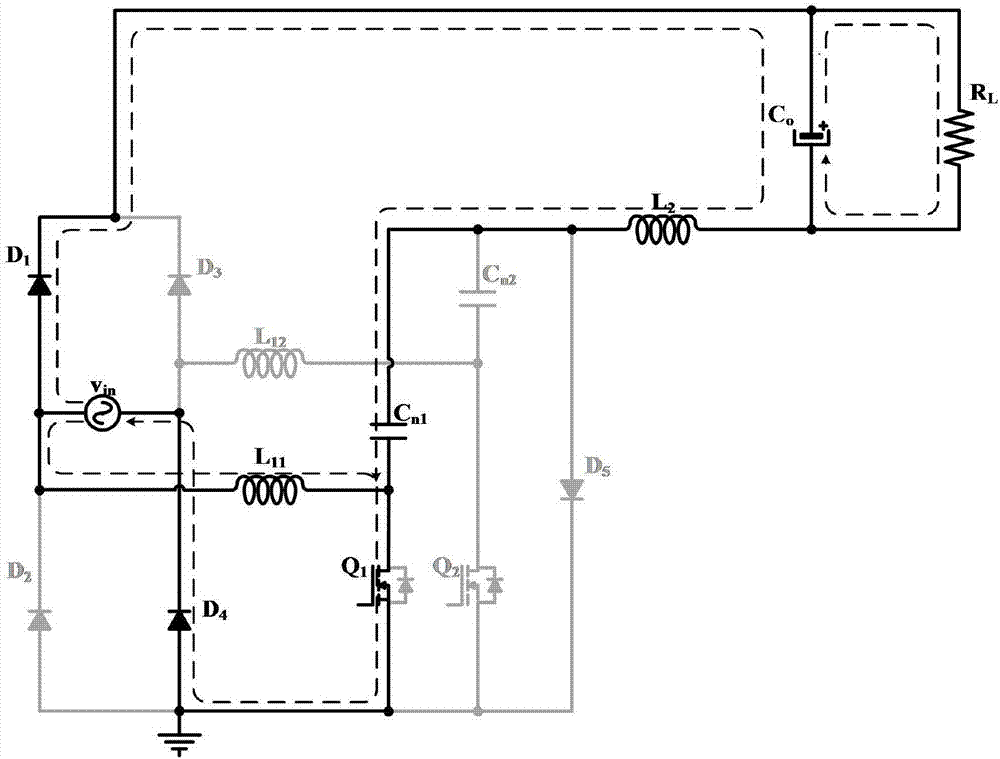

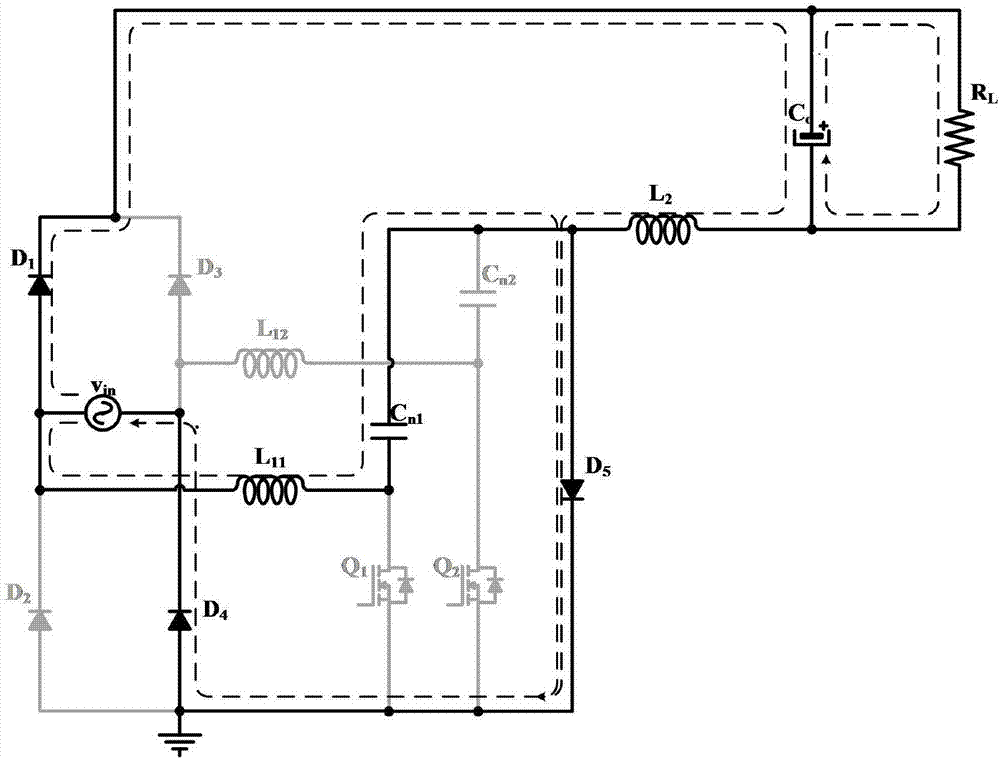

[0026] The present invention provides a bridgeless step-up Cuk PFC circuit, which provides AC-DC power conversion with low ripple, high efficiency and high power factor, such as figure 1 As shown, an input AC voltage source is provided, and an output terminal of the input AC voltage source is respectively connected to a first power diode D 1 anode of a second power diode D 2 The cathode and a first inductor L 11 One end of the input AC voltage source is connected to one end of the input AC voltage source respectively with a third power diode D 3 The anode of a fourth power diode and the cathode of a second inductor L 12 Connected to one end; the first inductance L 11 The other end of each is connected to a first power switch tube Q 1 The drain and a first intermediate capacitor C n1 connected to one end; the second inductance L 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com