Flame-retardant polyamide composition

A technology of flame-retardant polyamide and composition, applied in the field of flame-retardant polyamide composition, can solve the problems of discoloration and molecular weight reduction, insufficient inhibition, insufficient stabilizer activity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0232] 1. Components used

[0233] Commercial polyamide (component A)):

[0234] Polyamide 6.6 (PA 6.6-GV): A27 (BASF SE company, D)

[0235] Polyamide 6: B27 (BASF SE, D)

[0236] Component E): PPG HP 3610 glass fibers with a diameter of 10 microns and a length of 4.5 mm (PPG, NL)

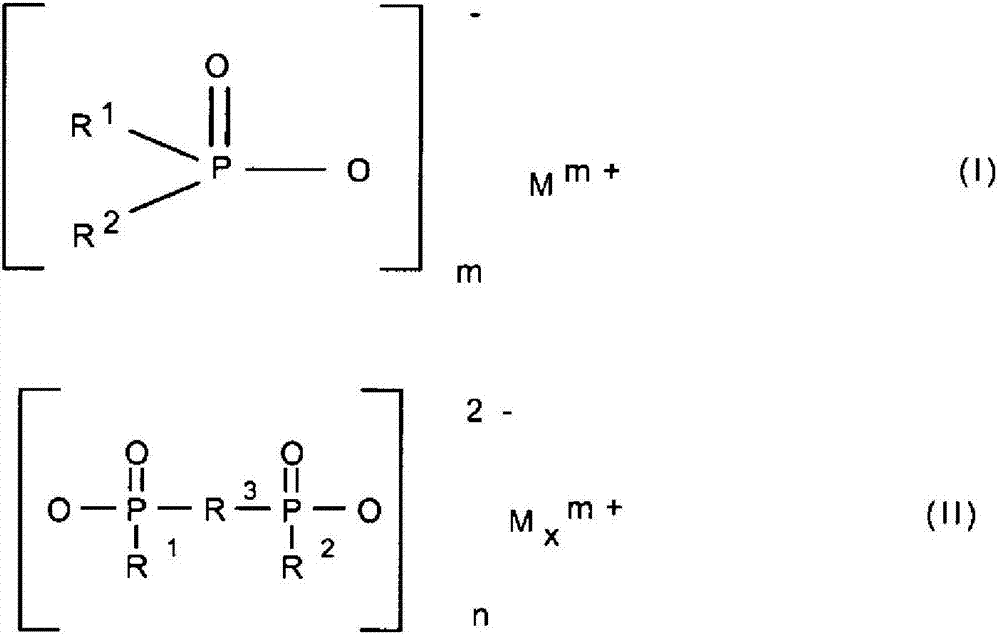

[0237] Flame retardant (component B)):

[0238] Aluminum salt of diethylphosphinic acid, hereinafter referred to as DEPAL

[0239] Flame retardant (component C)):

[0240] Aluminum salts of phosphorous acid, hereinafter called PHOPAL

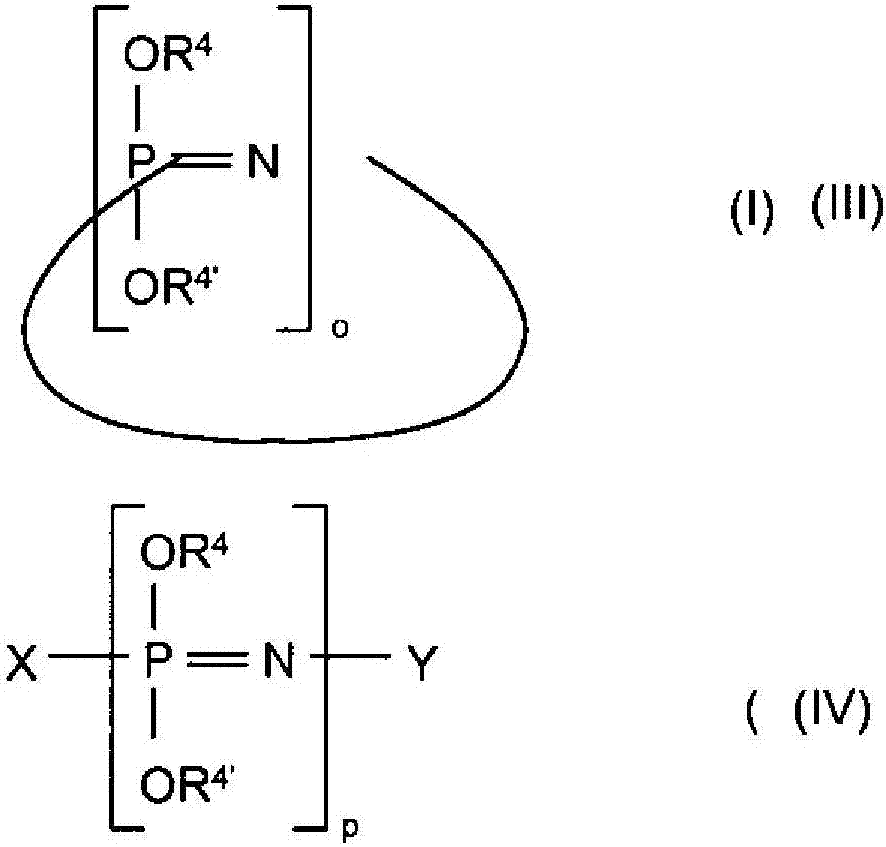

[0241] Flame retardant (component D)):

[0242] SPB 100, Otsuka Chemical Co., Japan

[0243] Rabitle FP 110, Fushimi Pharmaceuticals, Japan

[0244] Compare: MPP, Melamine Polyphosphate, 200 / 70, BASF AG, D

[0245] Phosphonite or salt (component F)): P-EPQ, Clariant GmbH, D

[0246] Wax Component (Component G)):

[0247] E, Clariant Produkte (Deutschland) GmbH company, D (ester of montan wax acid)

[0248] 2. Manufacture, processing and tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com