Intelligent combined machine tool

A compound and intelligent technology, applied in the directions of metal processing machinery parts, clamping, and support, can solve the problems of poor fixation of the cutter head, deviation of parts processing, single function, etc., to improve the fixing effect, high processing precision and stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

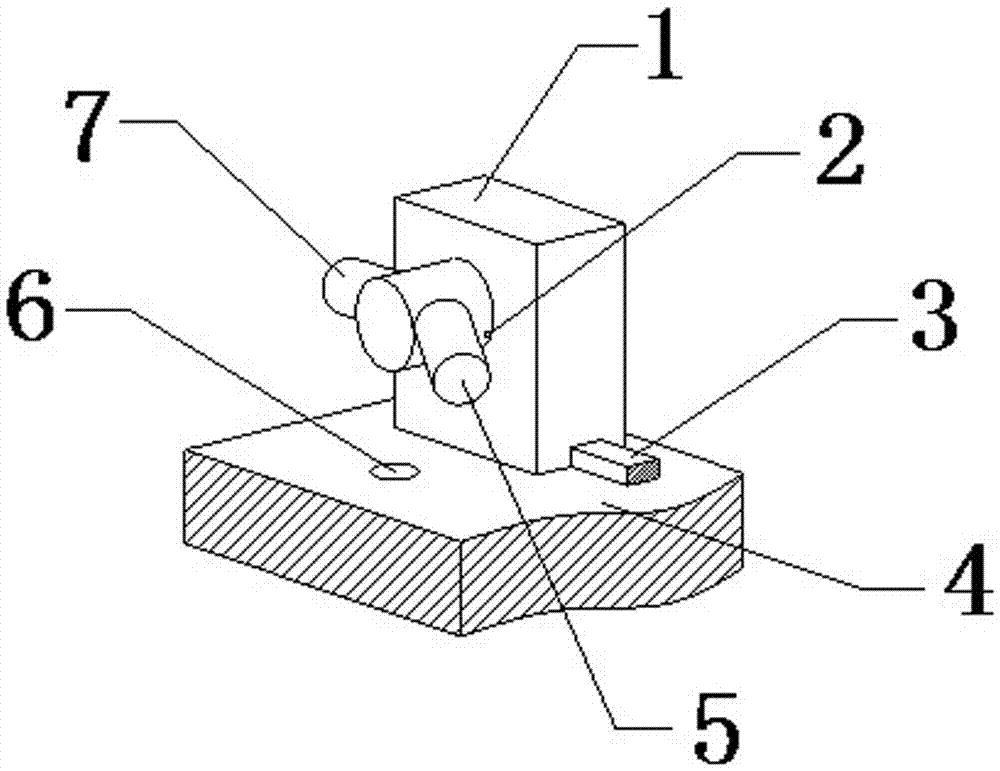

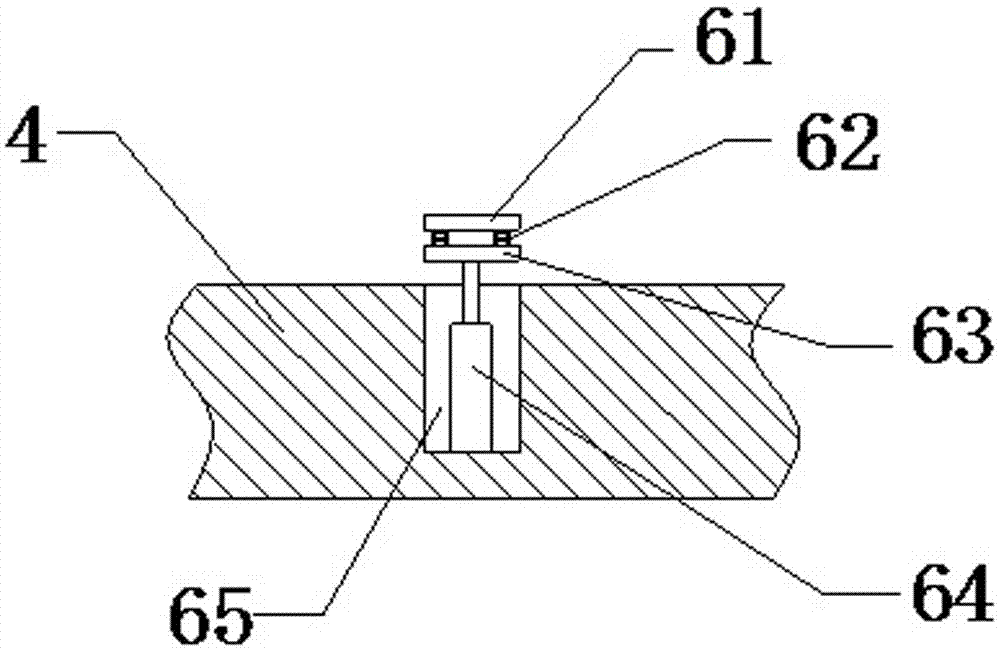

[0020] see Figure 1-Figure 3 , the present invention provides a technical solution: an intelligent compound machine tool, including a device body, a tool head switching fast fixing mechanism 2 and a tool verticality verification mechanism 6, the device body includes a tool head seat 1, a slide rail 3, a workbench 4. Knife seat 1 5 and knife seat 2 7, slide rail 3 is installed on the upper end surface of worktable 4, cutter head seat 1 is assembled on slide rail 3, knife seat 1 5 and knife seat 2 7 are symmetrically assembled on the rotating column 21 ring on the side.

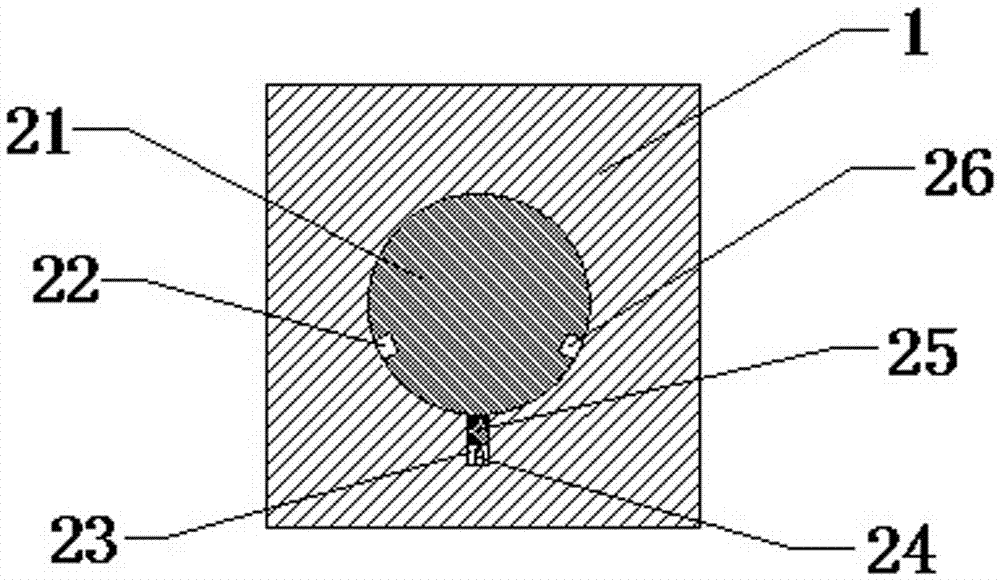

[0021] The cutter head switching fast fixing mechanism 2 comprises a rotating column 21, a square opening 22, a blind hole 23, an electric telescopic rod 1 24, a square block 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com