Double-jaw type carrying mechanical arm for aluminum alloy forged wheel hub

An aluminum alloy, manipulator technology, applied in manipulators, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of large usage, heavy weight, and the clamping jaw cannot be used for a long time, so as to improve efficiency and save processing. effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

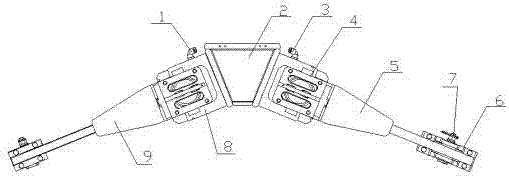

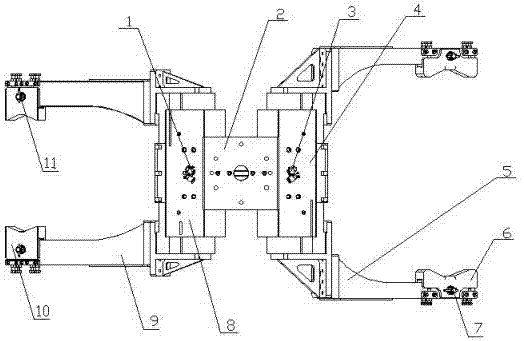

[0012] Depend on figure 1 , figure 2 It is a structural schematic diagram of the present invention, a double-claw type aluminum alloy forged wheel hub handling manipulator, which consists of a left air outlet 1, an intermediate connector 2, a right air outlet 3, a right synchronous cylinder 4, a right gripper arm 5, and a right V Type jaw block 6, right central shaft 7, left synchronous cylinder 8, left jaw arm 9, left V-shaped jaw block 10, left central shaft 11; the intermediate connector is used to connect the right synchronous cylinder and the left Synchronize the cylinder and the robot. The two surfaces on which the right and left synchronous cylinders are installed are symmetrically inclined at 22 degrees, so that the right and left synchronous cylinders are symmetrically inclined at 22 degrees. The working area is larger.

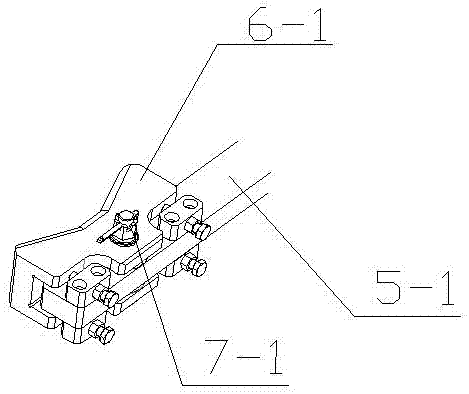

[0013] The right gas outlet 3 is installed on the right synchronous cylinder 4, the right V-shaped jaw block 6 is installed on the right jaw arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com