Thermochemical modified starch, preparation method and method for preparing adhesive by using thermochemical modified starch

A thermochemical and adhesive technology, applied in the direction of starch-derived adhesives, adhesive additives, adhesive types, etc., can solve problems such as high transportation costs, unsatisfactory water resistance, and complicated starch modification processes, and achieve Low transportation cost, excellent bonding strength and bonding water resistance, and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

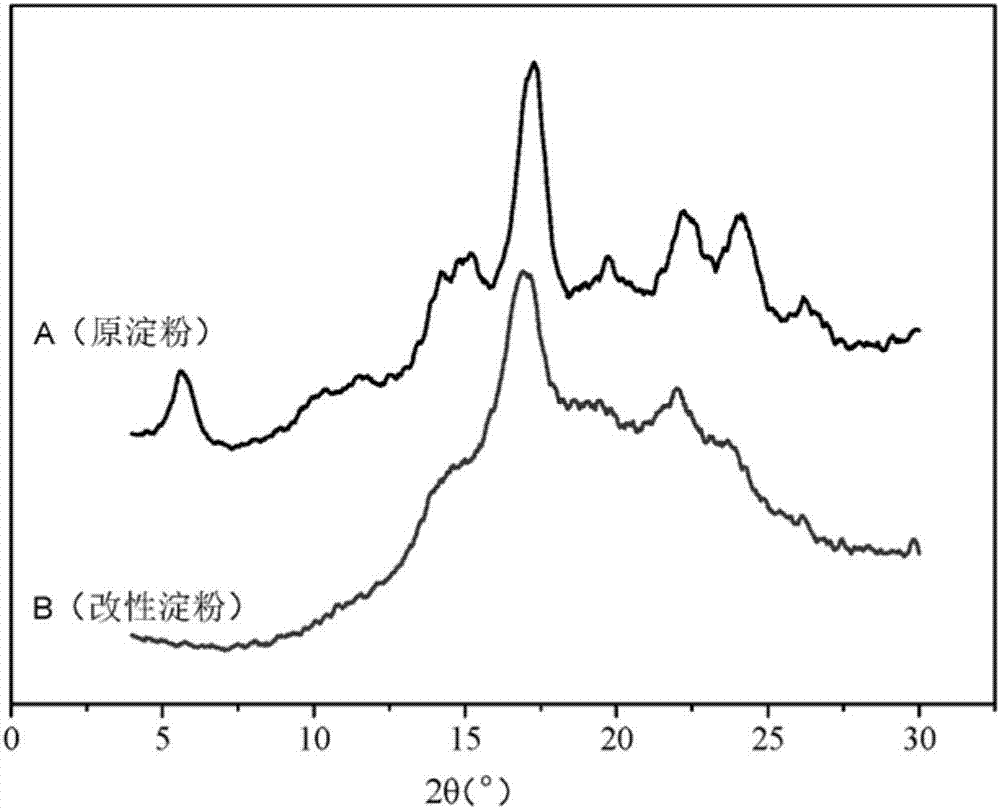

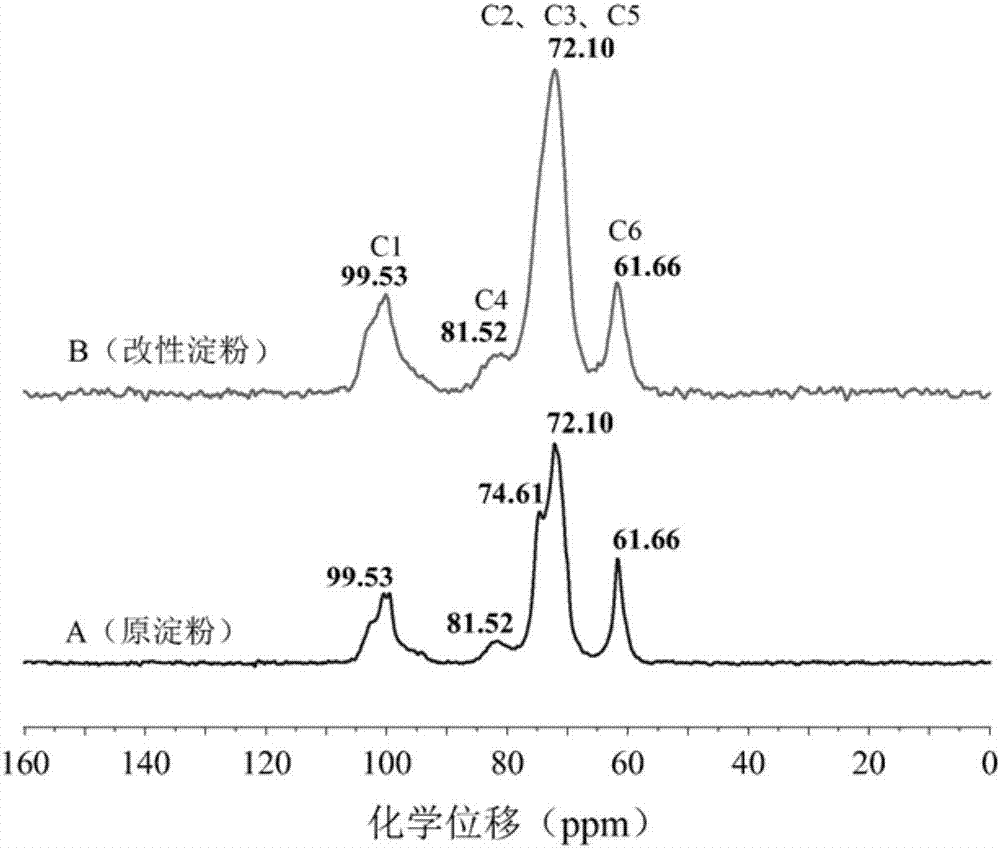

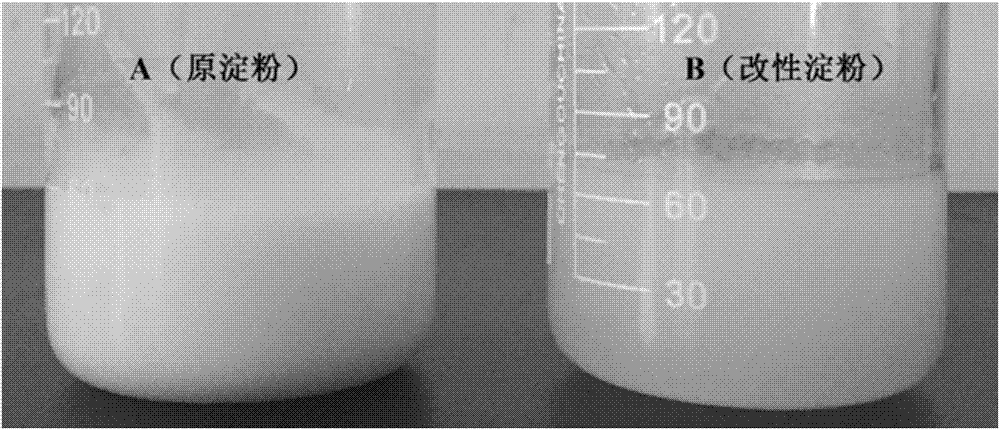

[0034] Specific embodiment 1: In this embodiment, thermochemically modified starch is uniformly sprayed into 100 parts of starch by weight parts of 10-70 parts of acid solution, and after mixing evenly, heat treatment is carried out at 70°C-110°C for 30-210 minutes , dried, cooled, and then crushed.

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment differs from Embodiment 1 in that the starch is one or a mixture of corn starch, wheat starch, potato starch, tapioca starch and sweet potato starch. Others are the same as in the first embodiment.

[0036] When the starch described in this embodiment is a mixture, the ratio between the components is arbitrary.

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass concentration of the acid solution is 1% to 20%. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com