Steel rail fat edge automatic grinding machine

A grinding machine and edge fattening technology, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of enlarged equipment outline size, unable to maintain transmission ratio, unstable grinding wheel speed, etc., so as to improve the swing flexibility and improve the The overall effect, the effect of enhancing the fineness of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

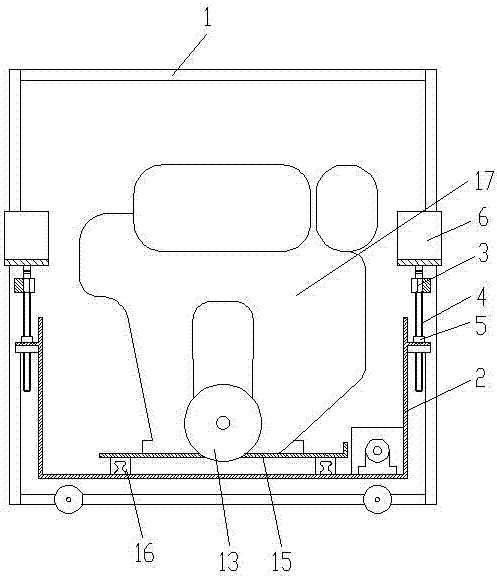

[0066] An automatic grinding machine for fat edges of rails, including a frame 1, and also includes an up and down moving device, a traveling device and a horizontal feeding device;

[0067] The up and down moving device comprises a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball nut 5 sleeved on the ball screw 4, and the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, The hanger 2 is slidingly connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 is connected with the ball bearing seat 3, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2 , the hanger 2 is connected with the ball screw 4 through the ball nut 5;

[0068] Described running gear comprises driving gear 8, driven gear 9, road wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, and driving gear 8 is connected with the motor shaft of motor 12, a...

Embodiment 2

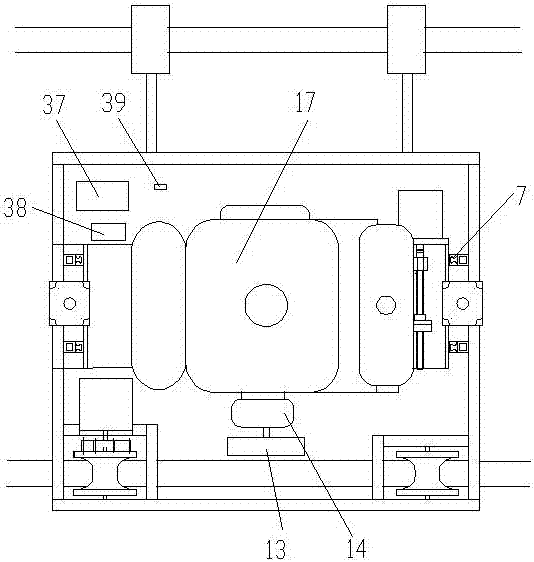

[0072] An automatic grinding machine for fat edges of rails, including a frame 1, and also includes an up and down moving device, a traveling device and a horizontal feeding device;

[0073] The up and down moving device comprises a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball nut 5 sleeved on the ball screw 4, and the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, The hanger 2 is slidingly connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 is connected with the ball bearing seat 3, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2 , the hanger 2 is connected with the ball screw 4 through the ball nut 5;

[0074] Described running gear comprises driving gear 8, driven gear 9, road wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, and driving gear 8 is connected with the motor shaft of motor 12, a...

Embodiment 3

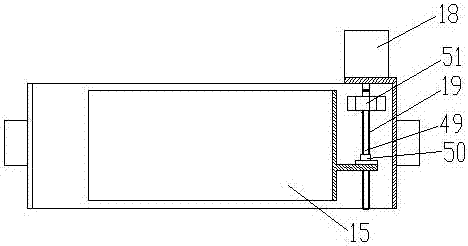

[0083] An automatic grinding machine for fat edges of rails, including a frame 1, and also includes an up and down moving device, a traveling device and a horizontal feeding device;

[0084] The up and down moving device comprises a hanger 2, a ball bearing seat 3, a ball screw 4 and a ball nut 5 sleeved on the ball screw 4, and the frame 1 is provided with a stepping motor 6 and an upper and lower slider 7, The hanger 2 is slidingly connected with the frame 1 through the upper and lower sliders 7, the motor shaft of the stepping motor 6 is connected with the ball bearing seat 3, one end of the ball screw 4 is connected with the ball bearing seat 3, and the other end runs through the hanger 2 , the hanger 2 is connected with the ball screw 4 through the ball nut 5;

[0085] Described running gear comprises driving gear 8, driven gear 9, road wheel 10, roller 11 and the motor 12 that is arranged on the frame 1, and driving gear 8 is connected with the motor shaft of motor 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com