Rapid evaluation tool and rapid evaluation method for weld quality of butt-fusion welding

A hot-melt butt joint and fast technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems that the test cannot be carried out on site, time, economic waste, and inconvenience of rapid construction, etc., to achieve Wide range of use, easy operation, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

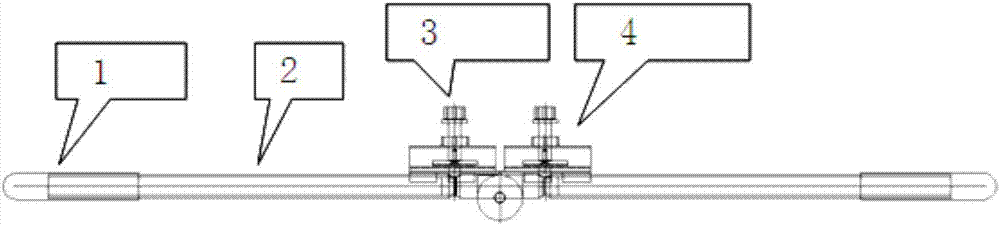

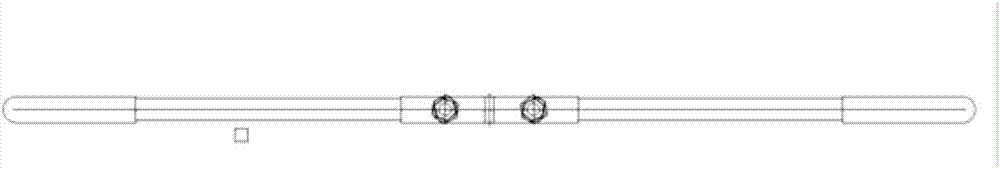

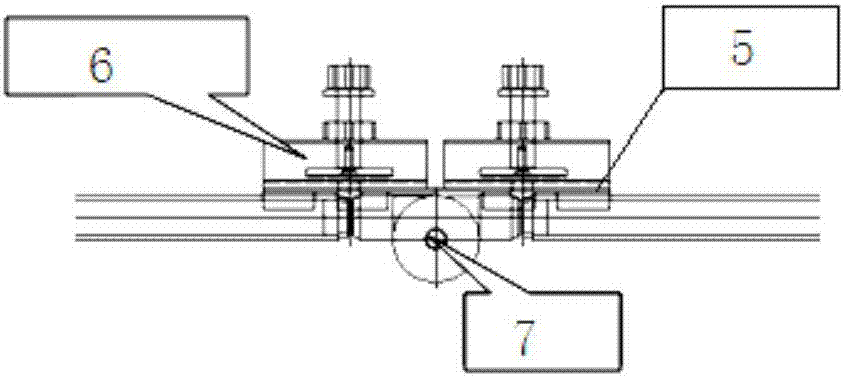

[0025] According to the standard requirements of GB / T 19810 "Determination of tensile strength and failure mode of hot-melt butt joints of polyethylene (PE) pipes and pipe fittings", the hot-melt butt joints of polyethylene (PE) pipes were processed into dumbbell-shaped samples, and the test A pulling force is applied at a constant velocity. When the sample is loaded on the tensile testing machine, the stress concentrates on the welded part and finally fails near the joint. The quality of hot-melt butt joints is judged by the failure mode and tensile strength, and the failure mode is as follows: Figure 4 as shown,

[0026] Among them, if the ductile fracture pattern occurs at or near the welding joint, the welding is judged to be qualified, and if the brittle fracture pattern occurs, the welding fails.

[0027] Due to reasons such as the grade of the material tested, the tensile yield strength of the weld joint cannot be given a standard value, and the welding quality is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com