Permanent magnet synchronous motor control method and system

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of control system, vector control system, motor generator control, etc., and can solve problems such as motor starting failure and large switching current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the embodiments of the present invention, and are not used to limit the embodiments of the present invention.

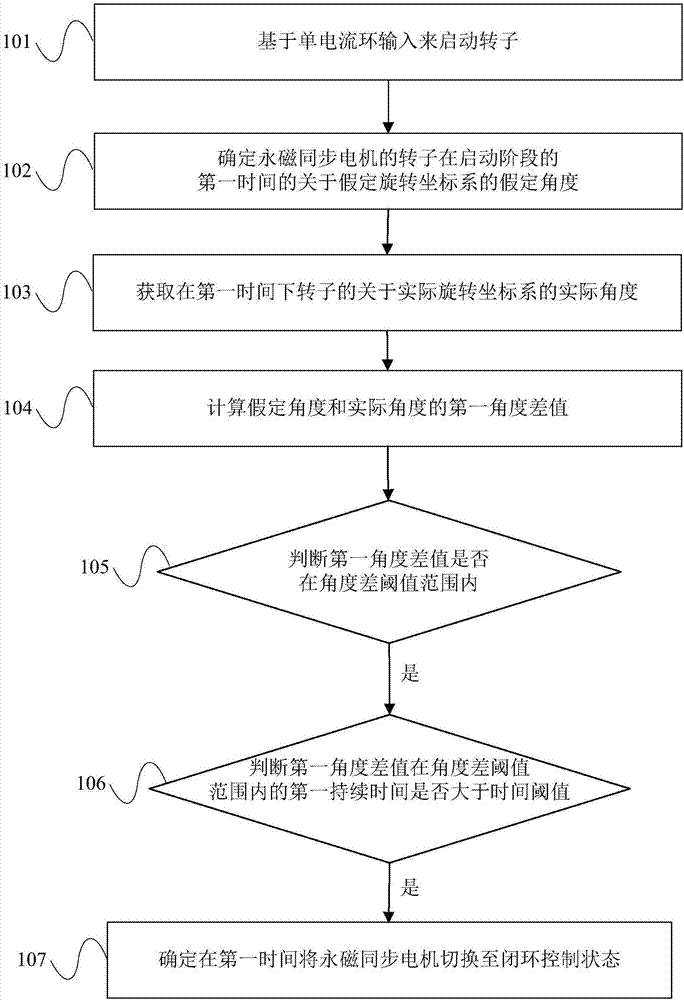

[0034] See figure 1 Shown is a schematic flow chart of a method for controlling a permanent magnet synchronous motor according to an embodiment of the present invention. The method specifically includes:

[0035] Step 101: Start the rotor based on the single current loop input;

[0036] Step 102: Determine the assumed angle of the rotor of the permanent magnet synchronous motor with respect to the assumed rotating coordinate system at the first time during the startup phase;

[0037] Step 103: Obtain the actual angle of the rotor with respect to the actual rotating coordinate system at the first time;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com