Device and method for extracting nicotine by using complete equipment of short-range distiller

A short-path distillation and complete set of equipment technology, applied in extractive distillation, tobacco, application and other directions, can solve the problems of low purity and low nicotine yield, and achieve the effect of reducing impurity content and preventing oxidative deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

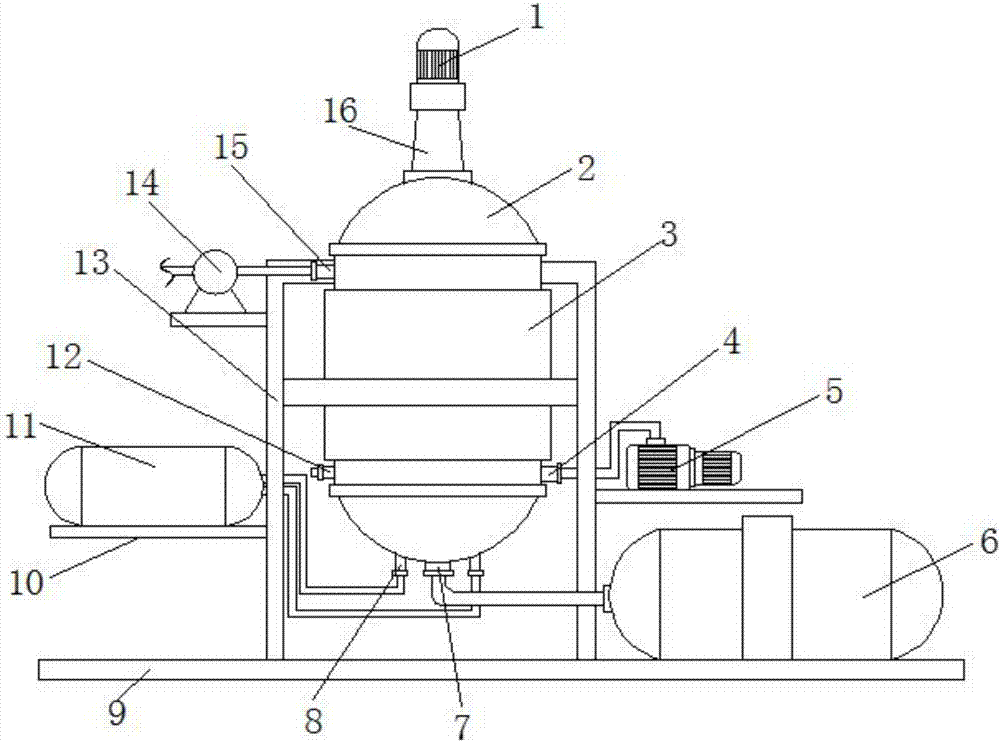

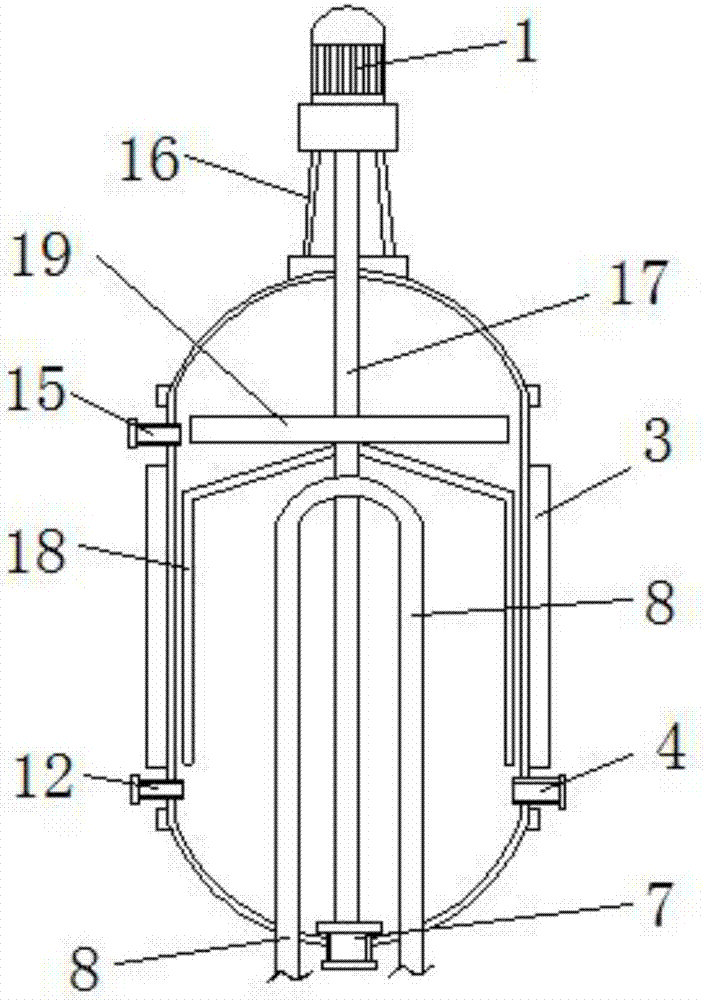

[0028] The present invention also provides a method for extracting nicotine by utilizing a complete set of short-path distillers, comprising the following steps:

[0029] S1. Pump the crude nicotine organic solution from the feed pump 14 to the feed port 15, and then enter the distillation tank 2 for short-path distillation and separation process, wherein the feed temperature of the short-path still is 62°C, and the heating mantle is used to 3. Heat the inside of the distillation tank 2 to 63°C, use the vacuum pump 5 to vacuumize the distillation tank 2, and control the pressure at 12Pa; The ratio of component to heavy component is controlled to be 2 / 3, and the rotating speed of film wiper 18 is controlled at 180r / min simultaneously.

[0030] S2. The final light component refined nicotine product is discharged into the collection tank 6 from the light component outlet 7 for storage.

[0031] The method for preparing the crude nicotine organic solution in S1 comprises the foll...

Embodiment 2

[0038] The present invention also provides a method for extracting nicotine by utilizing a complete set of short-path distillers, comprising the following steps:

[0039] S1. The crude nicotine organic solution is pumped from the feed pump 14 to the feed port 15, and then enters the distillation tank 2 for the short-path distillation separation process, wherein the feed temperature of the short-path still is 63°C, and the heating mantle is used to 3. Heat the inside of the distillation tank 2 to 65°C, use the vacuum pump 5 to vacuumize the distillation tank 2, and control the pressure at 13Pa; The ratio of component to heavy component is controlled to be 2 / 3, and the rotating speed of film wiper 18 is controlled at 190r / min simultaneously.

[0040] S2. The final light component refined nicotine product is discharged into the collection tank 6 from the light component outlet 7 for storage.

[0041] The method for preparing the crude nicotine organic solution in S1 comprises the ...

Embodiment 3

[0048] The present invention also provides a method for extracting nicotine by utilizing a complete set of short-path distillers, comprising the following steps:

[0049] S1. Pump the crude nicotine organic solution from the feed pump 14 to the feed port 15, and then enter the distillation tank 2 for short-path distillation and separation process, wherein the feed temperature of the short-path still is 65°C, and the heating mantle is used to 3. Heat the inside of the distillation tank 2 to 68°C, use the vacuum pump 5 to vacuumize the distillation tank 2, and control the pressure at 15Pa; The ratio of component to heavy component is controlled to be 2 / 3, and the rotating speed of film wiper 18 is controlled at 200r / min simultaneously.

[0050] S2. The final light component refined nicotine product is discharged into the collection tank 6 from the light component outlet 7 for storage.

[0051] The method for preparing the crude nicotine organic solution in S1 comprises the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com