Stackable drawing type adjustable sieve plate

A technology of extractable and sieve plate, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of increased production cost of sieve plate, unadjustable sieve plate, large use space, etc., achieves simple and reasonable structure and prolongs service life , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

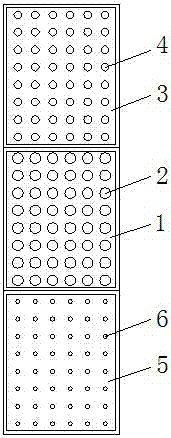

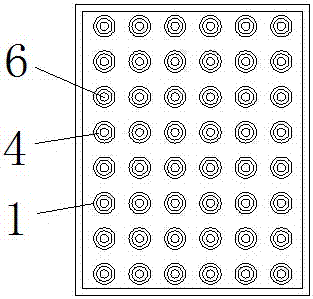

[0016] Such as figure 1 As shown, a superimposed and extractable adjustable sieve plate is formed by stacking the upper plate 1, the middle plate 3 and the bottom plate 5, and the upper plate 1, the middle plate 3 and the bottom plate 5 pass through Pull-out movement, the upper plate 1 is provided with evenly distributed large sieve holes 2, the middle plate 3 is provided with medium sieve holes 4, and the bottom plate 5 is provided with small sieve holes 6, when the upper plate 1, middle plate 3 and bottom plate After the plates 5 are synthesized, the large mesh holes 2, middle mesh holes 4 and small mesh holes 6 on their respective plates are all in a concentric state.

[0017] Such as figure 1 As shown, a superimposed extractable adjustable sieve plate, the upper plate 1, the middle plate 3 and the bottom plate 5 are moved by extracting, the upper plate 1 is in a motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com