Stepping type strip-shaped wood equidistant cutting device

An equidistant cutting and step-by-step technology, applied to wood processing equipment, sawing equipment, circular saws, etc., can solve the problems of low wood cutting efficiency, unfavorable production process, and stuck cutting tools, etc., and achieve a stable feeding process Uniform, avoid sharp rise, prevent over-concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

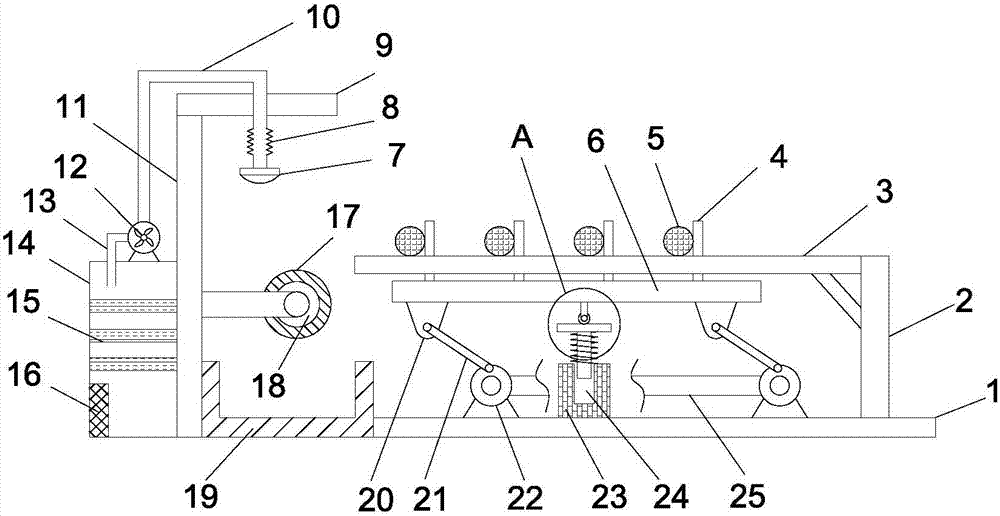

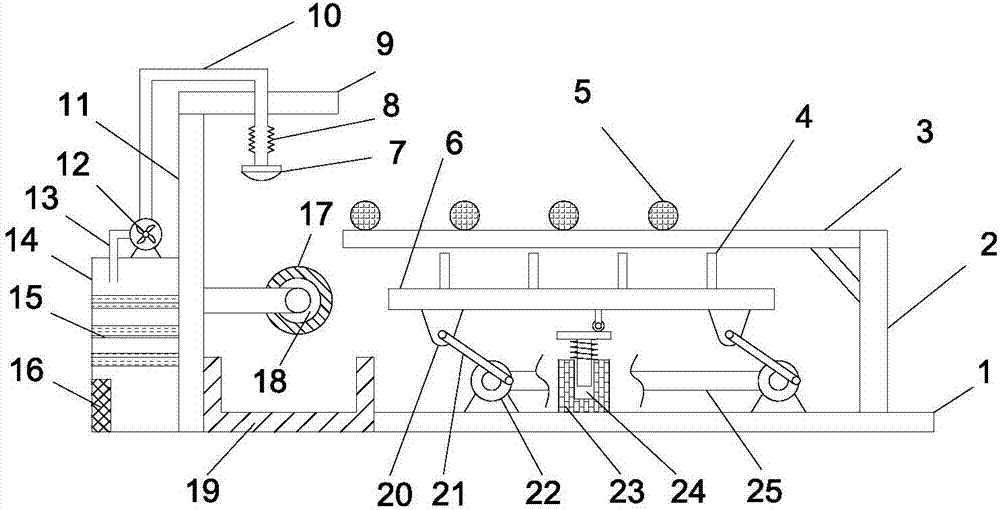

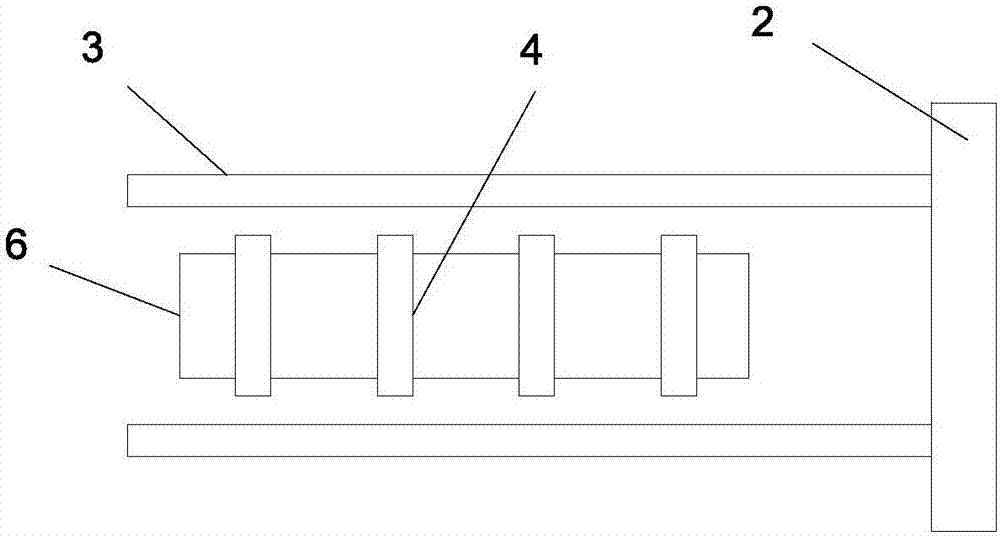

[0021] see Figure 1-5 , a step-by-step strip wood equidistant cutting device, comprising a base plate 1, characterized in that a vertical plate 2 is fixedly installed on the base plate 1, and two slide rails 3 are horizontally arranged on the vertical plate 2, and the two Two slide rails 3 are parallel to each other; two runners 22 are fixedly installed on the base plate 1, and a belt pulley mechanism 25 is connected on the two runners 22; guide rods 21 are all provided on the two runners 22; the base plate 1 The limit block 23 is fixedly installed on the limit block 23, and the limit groove 24 is longitudinally provided in the limit block 23. The limit groove 24 is a cylindrical hole groove, and the slide shaft 30 is slidably connected in the limit groove 24, and the slide shaft 30 is partially located In the bit groove 24, the top of the sliding shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com