A large amount of blast furnace heavy slag composite sand-based permeable brick and its efficient preparation method

A technology of blast furnace heavy slag and permeable bricks, which is applied in manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of limited source of raw materials, high cost, and complicated production process of pre-coated new sand, so as to alleviate the environment Effects of pollution, short hardening time, shortened setting and hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

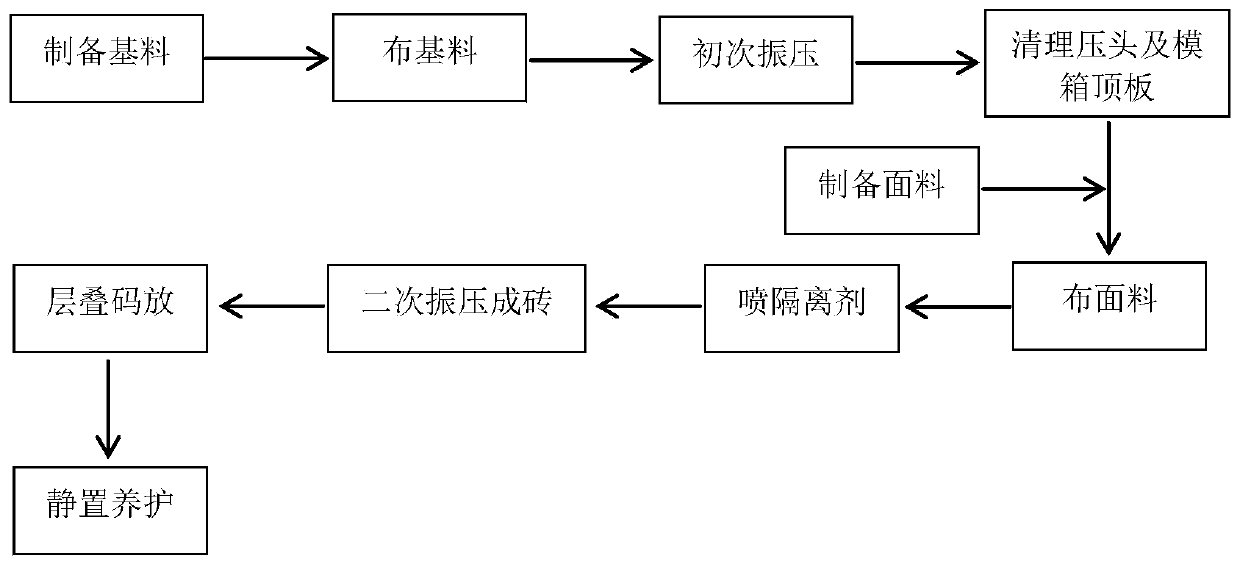

Method used

Image

Examples

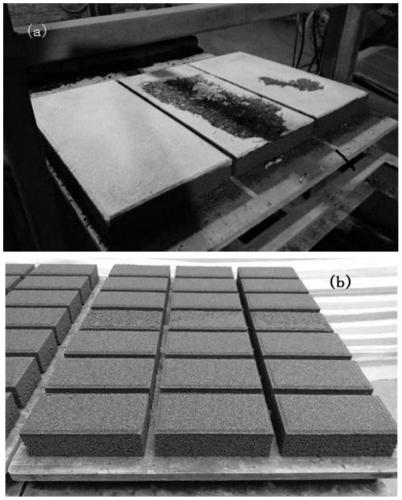

Embodiment 1

[0053] A large-volume heavy slag sand-based permeable brick includes a sand-based surface layer and a cement-based base layer. The material of the sand base surface layer is 200g of 20-40 mesh heavy slag superfine sand, 10.4g of 128 epoxy resin, 2.6g of aliphatic polyamine curing agent 531, 0.22g of coupling agent KH5500, and 0.2g of hardening accelerator DMP-30. Red color paste 0.1g; cement-based base material: 1mm-2mm heavy slag 200g, 3-5mm heavy slag 800g, P·O42.5 cement 174g, SAC42.5 cement 44g, polycarboxylate superplasticizer 0.11g, water 74g . After the surface layer and base layer materials were prepared, the automatic vibrating bricks were completed according to the production process. The ratio of the surface layer thickness to the base layer thickness of the prepared permeable bricks was 0.2:1. The performance parameter characterization results are shown in Table 1.

Embodiment 2

[0055] A large-volume heavy slag sand-based permeable brick includes a sand-based surface layer and a cement-based base layer. The material of the sand base surface layer is 200g of heavy slag superfine sand of 20-40 mesh, 13.3g of 128 epoxy resin, 3.3g of aliphatic polyamine curing agent 531, 0.13g of coupling agent KH5500, 0.1g of hardening accelerator DMP-30, Red color paste 0.1g; cement-based base material is 1mm-2mm heavy slag 200g, 3mm-5mm heavy slag 800g, P O52.5 cement 190g, SAC42.5 cement 48g, polycarboxylate superplasticizer 0.13g, water 79g . After the surface layer and base layer materials were prepared, the automatic vibrating bricks were completed according to the production process. The ratio of the surface layer thickness to the base layer thickness of the prepared permeable bricks was 0.2:1. The performance parameter characterization results are shown in Table 1.

Embodiment 3

[0057] A large-volume heavy slag sand-based permeable brick includes a sand-based surface layer and a cement-based base layer. The material of the sand base surface layer is 200g of heavy slag superfine sand of 20-40 mesh, 10.4g of 128 epoxy resin, 2.6g of aliphatic polyamine curing agent 593, 0.2g of coupling agent KH5500, 0.4g of hardening accelerator DMP-30, Red color paste 0.1g; cement-based base material is 150g of 1mm-2mm heavy slag, 950g of 3mm-5mm heavy slag, 153g of P·O42.5 cement, 65g of SAC42.5 cement, 0.11g of polycarboxylate superplasticizer, and 74g of water . After the surface layer and base layer materials were prepared, the automatic vibrating bricks were completed according to the production process. The ratio of the surface layer thickness to the base layer thickness of the prepared permeable bricks was 0.15:1. The performance parameter characterization results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com