A normal temperature synthetic environment-friendly polyurethane grouting plugging agent and preparation method thereof

A room temperature synthesis, polyurethane technology, applied in the field of waterproof materials, can solve the problems of slow reaction between secondary hydroxyl-terminated polyether and -NCO, insufficient activity of secondary hydroxyl-terminated polyether, and failure of normal industrial production, so as to reduce energy consumption , High production safety, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

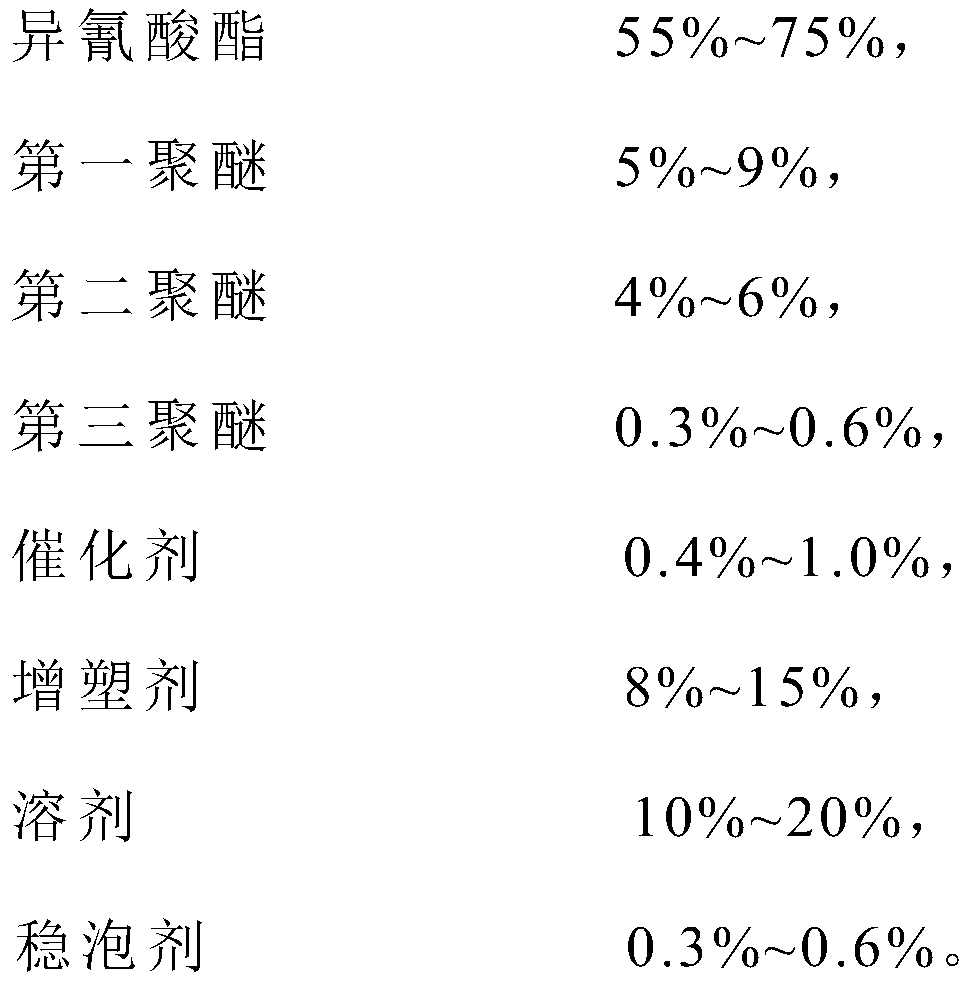

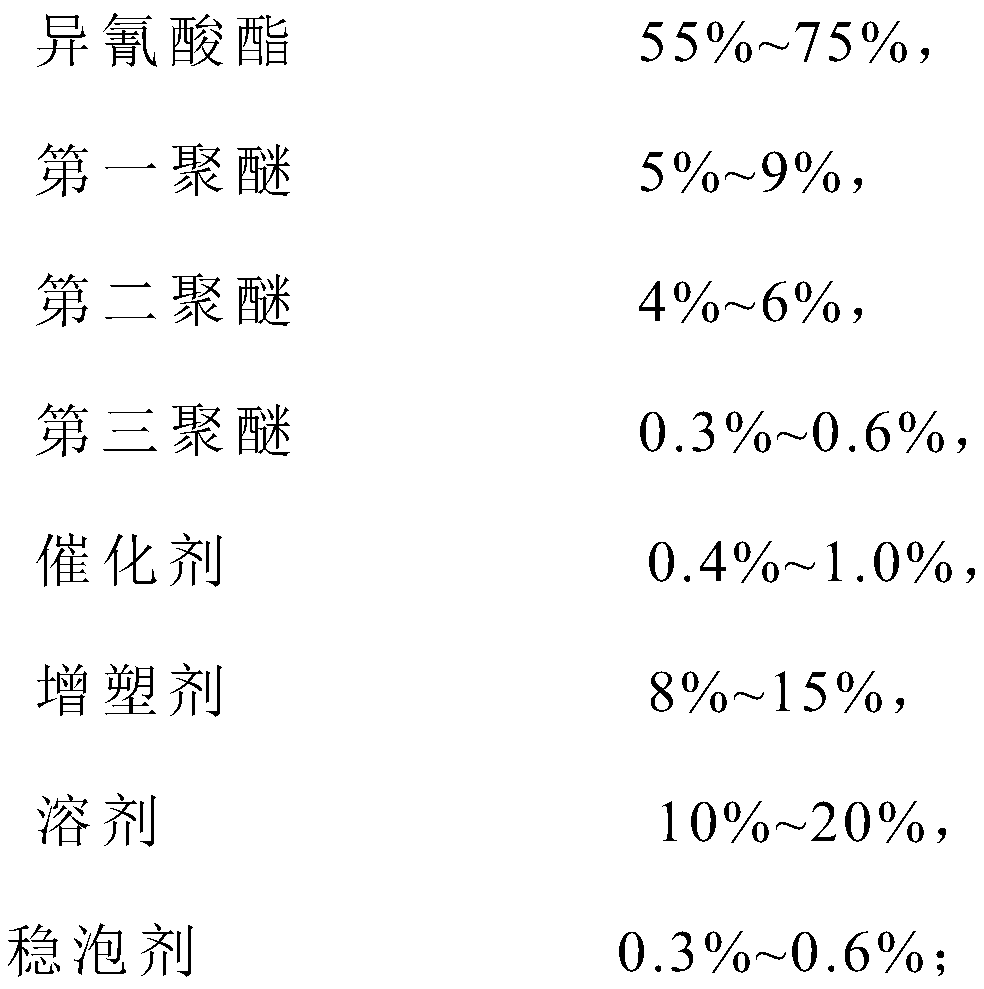

[0040] A normal temperature synthetic environment-friendly plugging material, the preparation process of which is as follows:

[0041] At room temperature (about 20°C), first add 9 parts of the first polyether, 4 parts of the second polyether, and 0.6 parts of the third polyether into the first reaction kettle, stir and mix evenly for later use, and add 65 parts of polymerized MDI-200 Add it into the second reaction kettle, start stirring (200~500r / min), then slowly add the polyether in the first reaction kettle into the second reaction kettle, and after stirring for 1 hour, add 0.6 parts of bismorpholinyl Put the diethyl ether catalyst in the second reactor, react at normal temperature for 3-4 hours, reduce the stirring speed (50-100r / min), add 10 parts of chlorinated paraffin and 10.3 parts of dichloromethane respectively in the second reactor, Stir for half an hour, add 0.5 parts of methyl silicone oil, continue stirring for half an hour, and then discharge.

Embodiment 2

[0043] A normal temperature synthetic environment-friendly plugging material, the preparation process of which is as follows:

[0044] At room temperature (about 20°C), first add 6 parts of the first polyether, 6 parts of the second polyether, and 0.4 parts of the third polyether into the first reaction kettle, stir and mix evenly for later use, and add 67 parts of polymerized MDI-200 Add it into the second reaction kettle, start stirring (200~500r / min), then slowly add the polyether in the first reaction kettle into the second reaction kettle, after stirring for 1 hour, add 0.8 parts of bismorpholino Put the diethyl ether catalyst in the second reactor, react at normal temperature for 3 to 4 hours, reduce the stirring speed (50 to 100r / min), add 8 parts of chlorinated paraffin, and 11.4 parts of dichloromethane into the second reactor respectively, Stir for half an hour, add 0.4 parts of methyl silicone oil, continue stirring for half an hour, and discharge.

Embodiment 3

[0046] A normal temperature synthetic environment-friendly plugging material, the preparation process of which is as follows:

[0047] At room temperature (about 20°C), first add 7 parts of the first polyether, 5 parts of the second polyether, and 0.6 parts of the third polyether into the first reaction kettle, stir and mix evenly for later use, and add 58 parts of polymerized MDI-200 Add it into the second reaction kettle, start stirring (200~500r / min), then slowly add the polyether in the first reaction kettle into the second reaction kettle, after stirring for 1 hour, add 0.4 parts of bismorpholinyl Put the diethyl ether catalyst in the second reactor, react at normal temperature for 3-4 hours, reduce the stirring speed (50-100r / min), add 14 parts of chlorinated paraffin, 14.5 parts of dichloromethane into the second reactor respectively, Stir for half an hour, add 0.5 parts of methyl silicone oil, continue stirring for half an hour, and then discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com