Stern oil composition and use thereof

An oil composition and technology for stern shafts, applied in the field of stern shaft oil compositions, can solve the problems of composite additives that do not consider biodegradability and biotoxicity, and achieve good biodegradability, excellent extreme pressure and anti-wear properties, initial The effect of low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] [Example 1] (in 100 grams, the same below)

[0028] Table 1

[0029]

[0030] Heat and stir pentaerythritol stearate and trihydroxypropane oleate at a constant temperature of 60°C to obtain mixed oil A. Add composite additive package ADDITIN M 93.001, sulfurized vegetable oil fatty acid ester, phosphate, succinic acid half ester derivatives to mixed oil A, and continue stirring for 40 minutes at a constant temperature of 60°C to prepare mixed oil B. Cool the mixed oil B at room temperature to obtain a clear and transparent lubricating oil for marine stern shafts. The properties are shown in Table 11.

Embodiment 2

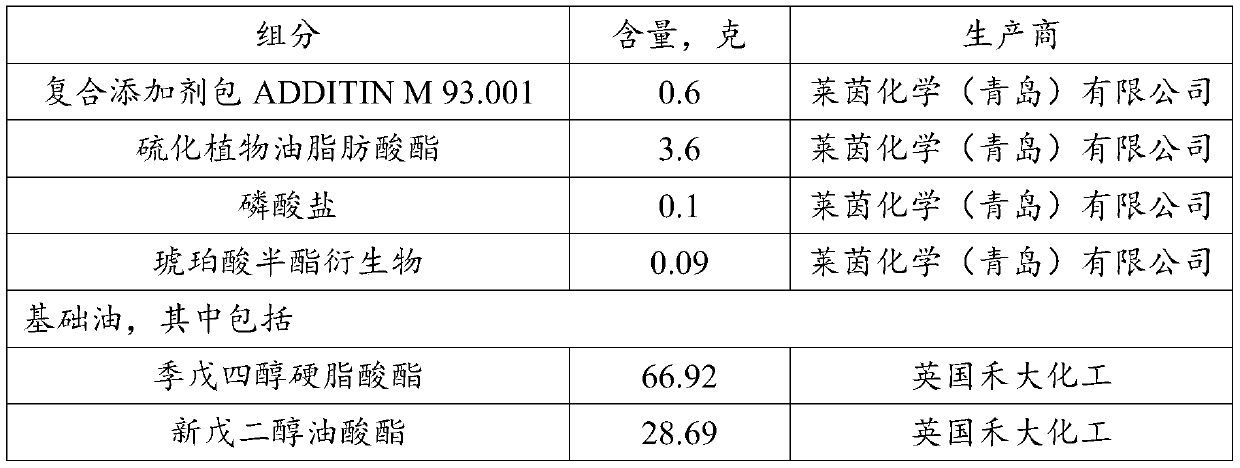

[0032] Table 2

[0033]

[0034] Heat and stir pentaerythritol stearate and neopentyl glycol oleate at a constant temperature of 60°C to obtain mixed oil A. Add composite additive package ADDITIN M 93.001, sulfurized vegetable oil fatty acid ester, phosphate, and succinic acid half ester derivatives to mixed oil A, and continue stirring for 40 minutes at a constant temperature of 60°C to prepare mixed oil B. Cool the mixed oil B at room temperature to obtain a clear and transparent lubricating oil for marine stern shafts. The properties are shown in Table 11.

Embodiment 3

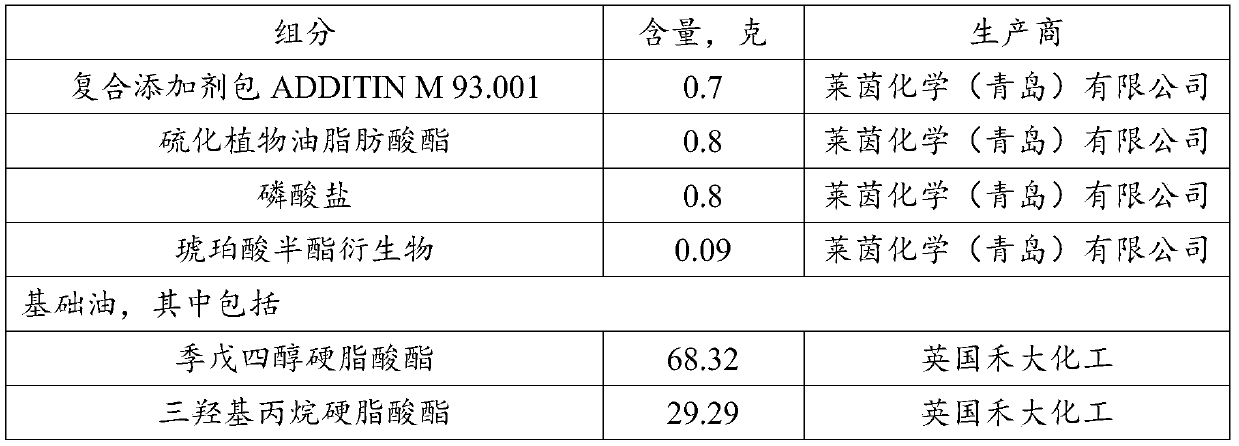

[0036] table 3

[0037]

[0038] Heat and stir pentaerythritol stearate and trihydroxypropane stearate at a constant temperature of 60°C to obtain mixed oil A. Add composite additive package ADDITIN M 93.001, sulfurized vegetable oil fatty acid ester, phosphate, succinic acid half ester derivatives to mixed oil A, and continue stirring for 40 minutes at a constant temperature of 60°C to prepare mixed oil B. Cool the mixed oil B at room temperature to obtain a clear and transparent lubricating oil for marine stern shafts. The properties are shown in Table 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com