Noise reduction structure of engine oil bottom shell

An engine oil and noise reduction technology, which is applied in the direction of engine lubrication, oil pan, engine components, etc., can solve the problems of high cost of transformation, poor technical effect, high cost, etc., and achieve fast transformation, good noise reduction effect, The effect of low renovation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

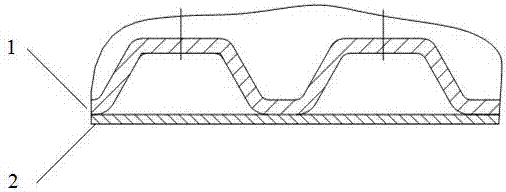

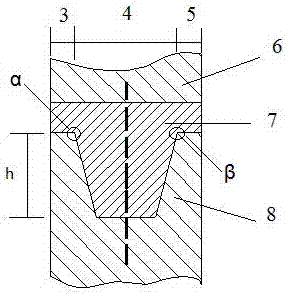

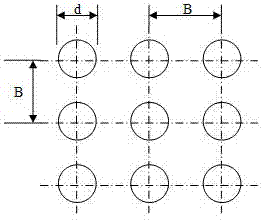

[0032] The noise reduction structure includes: engine oil pan; resonant sound-absorbing plate, the resonant sound-absorbing plate is set on the inner side wall of the engine oil pan, and there are several through holes on the resonant sound-absorbing plate, the holes on the resonant sound-absorbing plate are circular The diameter of the circular hole is d, the center distance of the circular hole is B, the perforation rate σ is proportional to the square of the ratio of d and B, and σ is 0.01, and the diameter d is 3mm; and high damping vibration isolation Rubber pad, the high damping vibration isolation rubber pad is set between the top end surface of the oil pan and the connection surface of the crankcase, the high damping vibration isolation rubber pad includes the first part, the second part and the third part, the high damping vibration isolation rubber pad The cross-sections of the first and second parts are rectangular, the cross-section of the third part of the high-dam...

Embodiment 2

[0034] Replace some parameters in Example 1 as follows: σ is 0.08, diameter d is 6.5mm; height (h) of the trapezoidal part is 30mm, first inclination angle (α) is 80° and second inclination angle (β) is 77 °, the length of the bottom side of the third part is greater than the sum of the lengths of the bottom sides of the first part and the second part. Among them, the thickness of the resonant sound-absorbing panel is 6 mm, and the thickness of the resonant sound-absorbing panel is smaller than the diameter d, and the B range of the resonant sound-absorbing panel is 16 mm. The first angle of inclination is 3° greater than the second angle of inclination, the length of the bottom side of the first portion is the same as the length of the bottom side of the second portion, and the length of the bottom side of the third portion is three times the length of the bottom side of the first portion The high-damping vibration-isolation rubber pad has a three-layer structure, in which bu...

Embodiment 3

[0036] Replace some of the parameters in Example 1 as follows: σ is 0.04, diameter d is 5mm; the height (h) of the trapezoidal part is 20mm, the first inclination angle (α) is 70° and the second inclination angle (β) is 68 °, the length of the bottom side of the third part is greater than the sum of the lengths of the bottom sides of the first part and the second part. Wherein, the thickness of the resonant sound-absorbing panel is 4 mm, and the thickness of the resonant sound-absorbing panel is smaller than the diameter d, and the B range of the resonant sound-absorbing panel is 15 mm. The first angle of inclination is 2° greater than the second angle of inclination, the length of the bottom side of the first portion is the same as the length of the bottom side of the second portion, and the length of the bottom side of the third portion is three times the length of the bottom side of the first portion times, the high-damping vibration-isolation rubber pad is a single-layer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com