Pulverized coal conveying quantity control system for steel ball mill

A technology of conveying control and steel ball milling, which is applied in the control of combustion, block/powder fuel preparation, combustion method, etc., can solve the problems of destroying water circulation, swelling, and large deviation of the heat of the burner, so as to reduce the amount of NOx generated. , The effect of reducing heat deviation and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

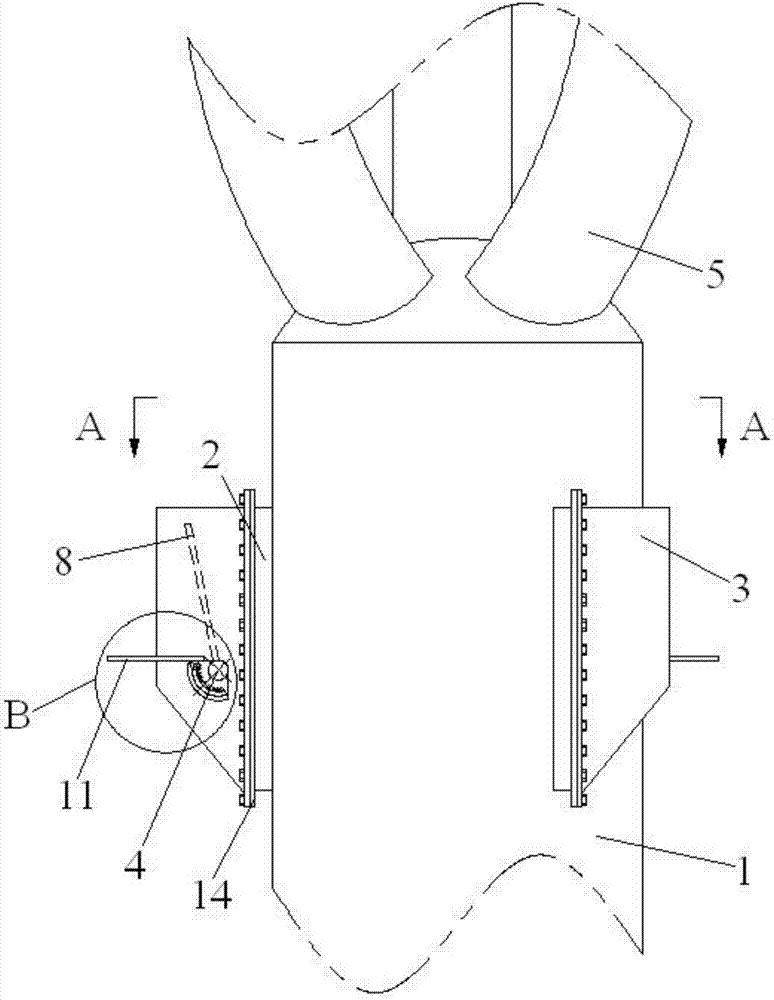

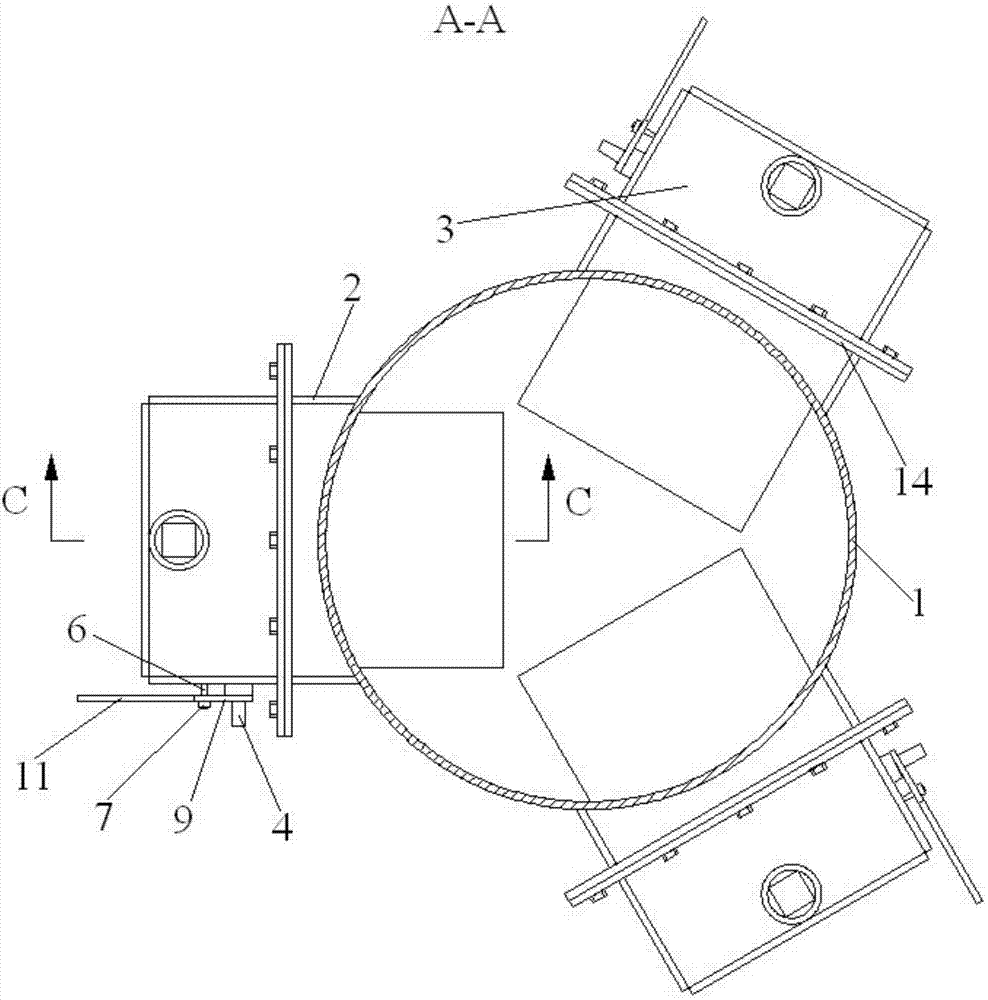

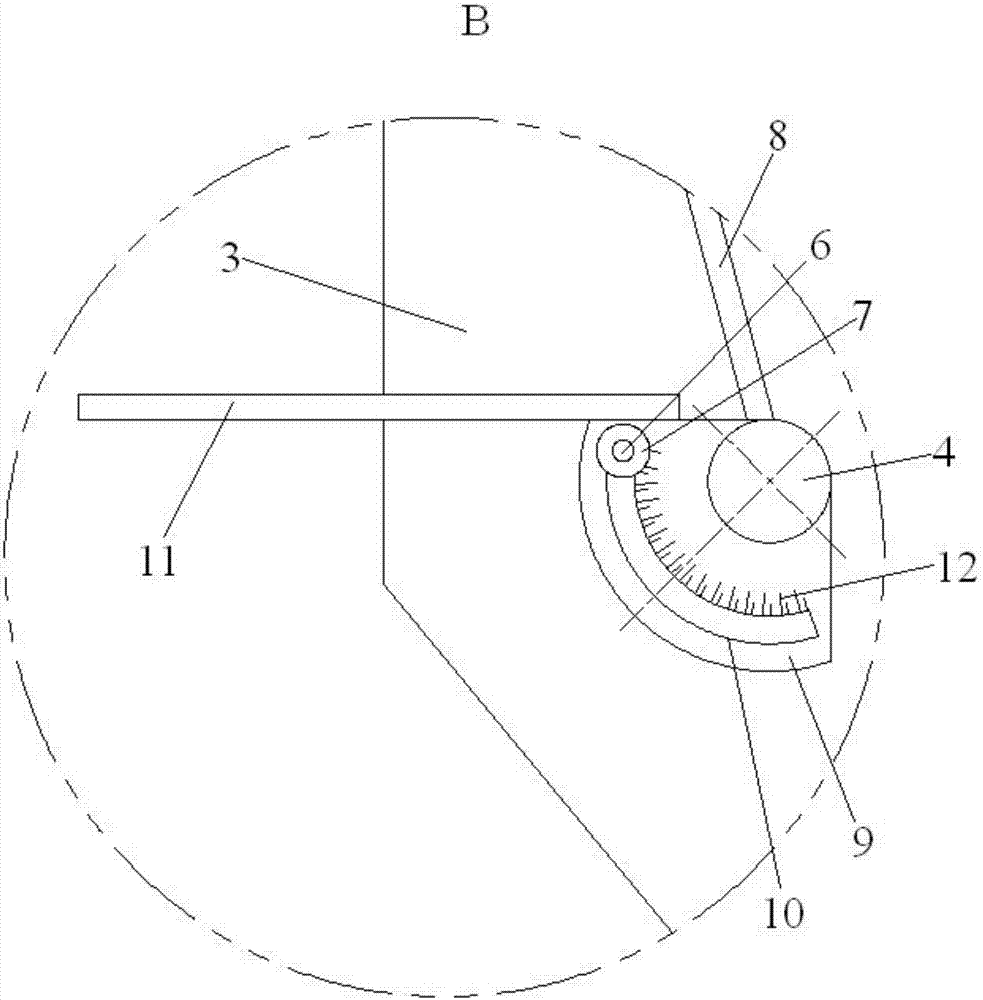

[0029] refer to Figure 1 to Figure 4 , the embodiment of the present invention proposes a steel ball mill coal delivery control system, which is used to control the pulverized coal delivery in multiple pulverized coal pipelines 5 connected to the pulverized coal main pipe 1, including: multiple connecting seats 2, A plurality of fixed covers 3 and a rotating shaft 4; a plurality of connecting seats 2 are symmetrically fixedly connected on the side wall of the pulverized coal main pipe 1, and one end of each connecting seat 2 communicates with the inner side of the pulverized coal main pipe 1, and the opening at the other end A connection edge 14 is provided; the end of each fixed cover 3 is connected with the connection edge 14 on the opening of the connection seat 2; the rotating shaft 4 is rotatably assembled between the two side walls of the fixed cover 3, and the rotating shaft 4 is connected to the pulverized coal mother The axes of the pipe 1 are vertical, the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com