Novel charging gun and manufacturing method thereof

A manufacturing method and charging gun technology, applied in charging stations, electric vehicle charging technology, circuits, etc., can solve problems such as increased production costs and production processes, short circuit of charging guns, poor waterproof performance, etc., to ensure charging effect and safety, Effect of improving overall strength and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

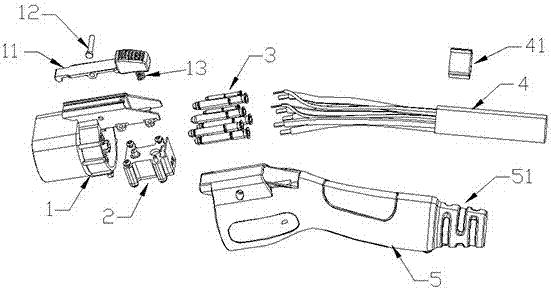

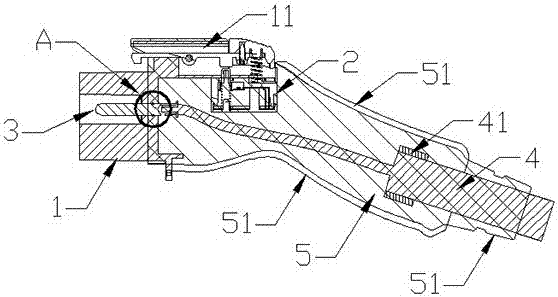

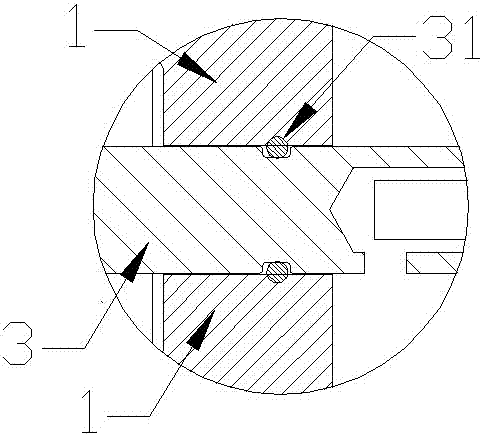

[0052] see figure 1 and figure 2 , in the embodiment of the present invention, a new type of charging gun and its manufacturing method, comprising, a charging plug 1, a charging terminal 3 and a charging wire 4, the upper end of the charging plug 1 is provided with a locking member 11 that is buckled with a socket at one end, The middle part of the locking member 11 is fixedly connected to the charging plug 1 through a fixing pin 12, and a spring 13 is provided between the other end of the locking member 11 and the charging plug 1. When the spring 13 springs up, the locking member 11 The other end of the locking member 11 moves upward under the action of the spring 13, and one end of the locking member 11 moves downward with the fixed pin 12 as the axial direction, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com