UV (Ultraviolet) curing fluorine-silicon release agent and preparation method thereof

A light-curing and release agent technology, applied in coatings and other directions, can solve the problems of high-temperature curing and expensive catalysts, and achieve the effect of energy-saving applicability and excellent release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

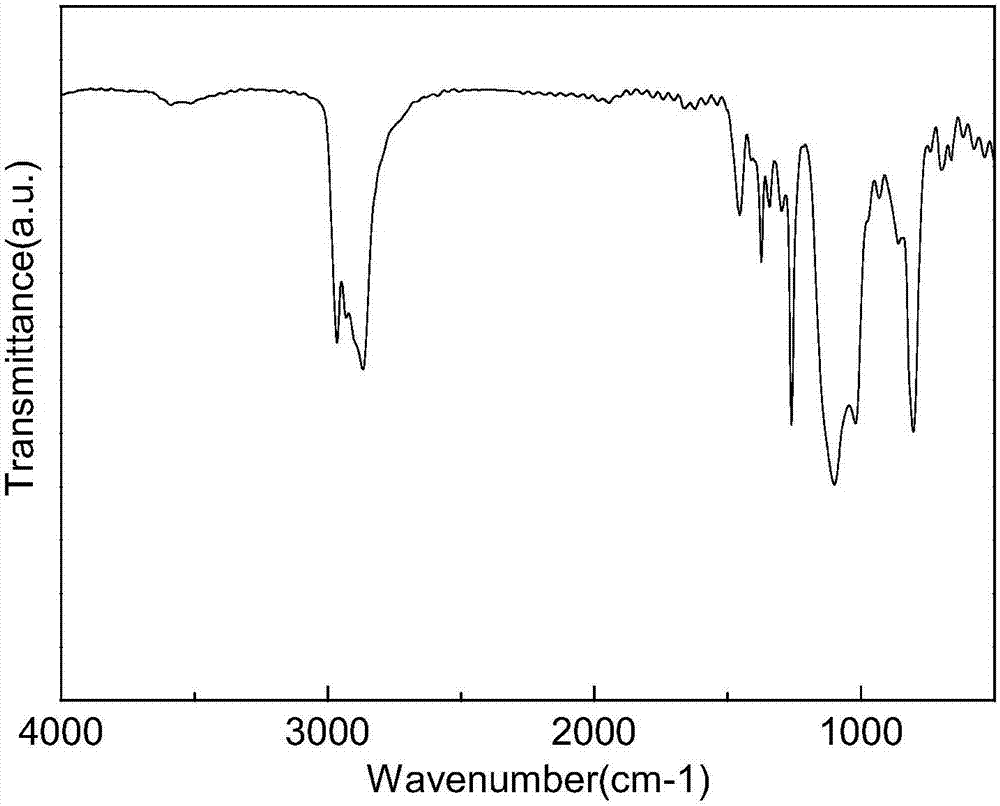

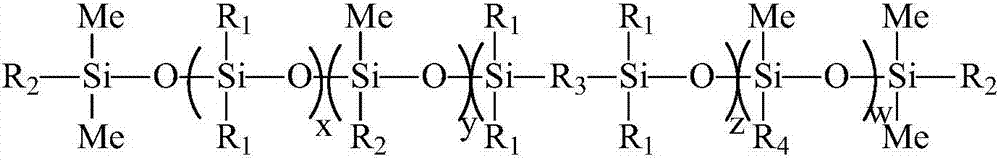

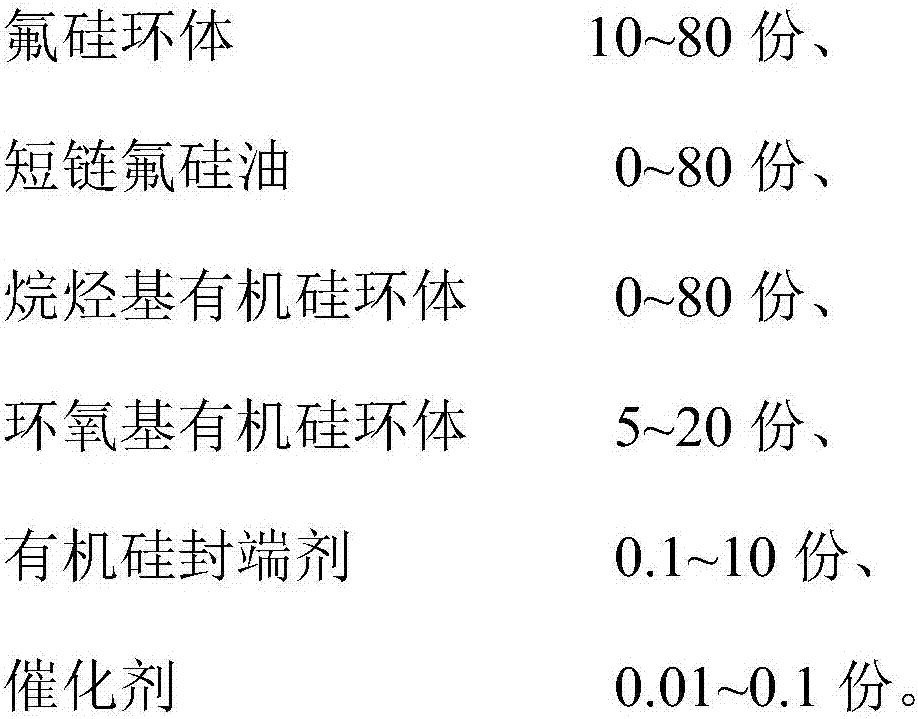

[0033] Pentamethyl perfluorooctyl cyclotrisiloxane 10mol, octamethylcyclotetrasiloxane 40mol, glycidyl ether propyl heptamethylcyclotetrasiloxane 5mol, glycidyl ether propyl tetramethyldisiloxane Add 0.2 mol of oxane into the reaction kettle, reduce the pressure, feed nitrogen and remove moisture at 50°C, heat up to 75°C, add 0.1mol trifluorosulfonic acid, react for 10h, add alkali to neutralize the catalyst, and then heat up After removing low-boiling silicone oil at 150°C, cool and filter to obtain a colorless and transparent UV-curable fluorosilicone release agent. Infrared spectrum such as figure 1 As shown, the structural formula is as follows:

[0034]

[0035] The prepared UV photocurable fluorosilicone release agent and HPF 6 After mixing evenly, it is coated on a PET film and cured by UV light to obtain a release coating. Its performance test is as follows:

[0036] Table 1. Contact angle and surface energy tests

[0037]

water

Diiodomethane ...

Embodiment 2

[0041] Pentamethylperfluoroether trisiloxane 30mol, short chain fluorosilicone oil 10mol, octamethylcyclotetrasiloxane 10mol, glycidyl ether propyl hexamethylcyclotetrasiloxane 10mol, glycidyl ether propyl tetramethicone Add 0.1mol into the reaction kettle, depressurize to 0.09Mpa, feed nitrogen and remove moisture at 50°C, heat up to 120°C, add 0.1mol KOH, react for 10h, add acid to neutralize the catalyst, and heat up to 200°C After removing low-boiling silicone oil at ℃, cool and filter to obtain colorless and transparent fluorosilicone oil.

[0042] The prepared fluorosilicone and HPF 6 After mixing evenly, it is coated on a PET film and cured by UV light to obtain a release coating. Its performance test is as follows:

[0043] Table 3. Contact angle and surface energy tests

[0044]

water

Contact Angle / Surface Energy

120°

89°

[0045] Table 4. Release performance and heat resistance test

[0046]

Embodiment 3

[0048] Pentamethylperfluorooctylcyclotrisiloxane 60mol, short-chain fluorosilicone oil Add 40mol, 20mol of glycidyl ether propyl heptamethylcyclotetrasiloxane, 5mol of glycidyl ether propyl tetramethyldisiloxane into the reaction kettle, reduce the pressure, and remove the moisture after nitrogen gas is introduced and at 50°C After that, heat up to 75°C, add 0.01mol trifluorosulfonic acid, react for 10h, add alkali to neutralize the catalyst, heat up to 150°C to remove low-boiling silicone oil, cool and filter to obtain a colorless and transparent UV light-curable fluorosilicone release agent .

[0049] The prepared UV photocurable fluorosilicone release agent and HPF 6 After mixing evenly, it is coated on a PET film and cured by UV light to obtain a release coating. Its performance test is as follows:

[0050] Table 5. Contact angle and surface energy tests

[0051]

water

Contact Angle / Surface Energy

118°

88°

[0052] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com