A preparation process of isothermally solidified large liner

A preparation process and liner technology, applied in the field of materials, can solve the problems of lack of beneficial ingredients in the core of the liner, affecting the structure and performance of the core of the liner, poor wear resistance of the core of the liner, etc., to achieve uniform internal and external components and low cost. Low, full core feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

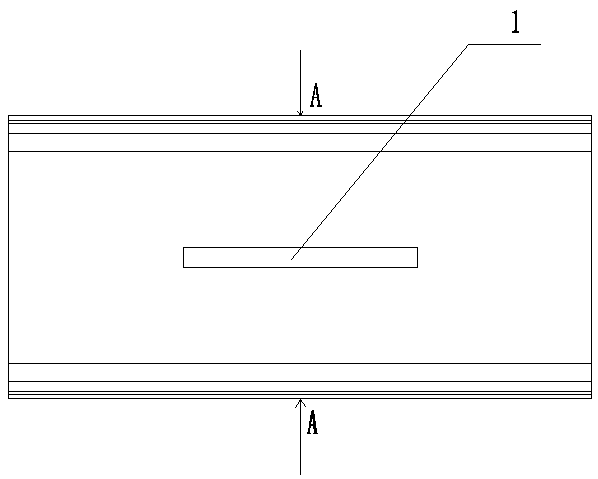

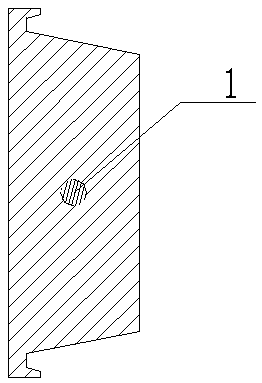

[0046] The large lining plate prepared in this example is used on a semi-autogenous mill with a diameter of 10.3m. The maximum size of the lining plate is 340mm*960mm*1980mm, the unit weight is 2.35T, and the material is alloy steel. The specific composition is as follows:

[0047] Table 1: Composition Table of Lining Board of Embodiment 1

[0048]

[0049] Calculated according to formulas (1)-(5), the complete liquidus temperature of the above materials is 1478°C, tapped and cast at room temperature 20°C and 1580°C, and the mass of the built-in chilled iron is 91.8Kg; solidification intervention conditions (built-in chilled iron ) The overall dimensions are 796mm in length and 68mm in radius; the placement position is the center of the liner.

[0050] The preparation method of the large liner of the present embodiment comprises the following steps:

[0051] ①According to the above calculation results, prepare a built-in cold iron with qualified size and composition, and f...

Embodiment 2

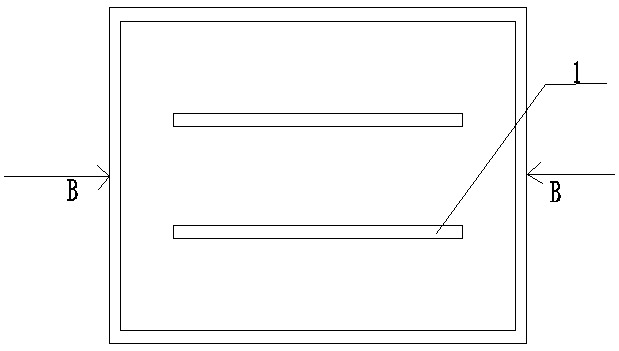

[0057]The large lining plate prepared in this example is a large lining plate used on a jaw crusher. The maximum outer dimension of the lining plate is 1557mm*1256mm*197mm, the unit weight is 2.12T, and the material is high-manganese steel. The specific composition is as follows:

[0058] Table 2: Composition Table of Lining Board of Embodiment 2

[0059]

[0060] Calculated according to formulas (1)-(5), the complete liquidus temperature of the above material is 1395°C, tapped and cast at room temperature 20°C and 1550°C, and the mass of the built-in chilled iron is 125Kg; solidification intervention conditions (built-in chilled iron) The overall dimensions are 1080mm in length and 68.5mm in radius. Considering the width (1256mm) direction factor, under the condition that the total mass of the built-in cooling iron remains unchanged, the original built-in cooling iron with a length of 1080mm and a radius of 68.5mm is replaced by two built-in cooling irons with a length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com