High-pressure water discharging cutter tower assembly of numerically-controlled lathe

A technology for CNC lathes and turrets, which is applied to tools for lathes, accessories of toolholders, turning equipment, etc. The effect of accelerated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

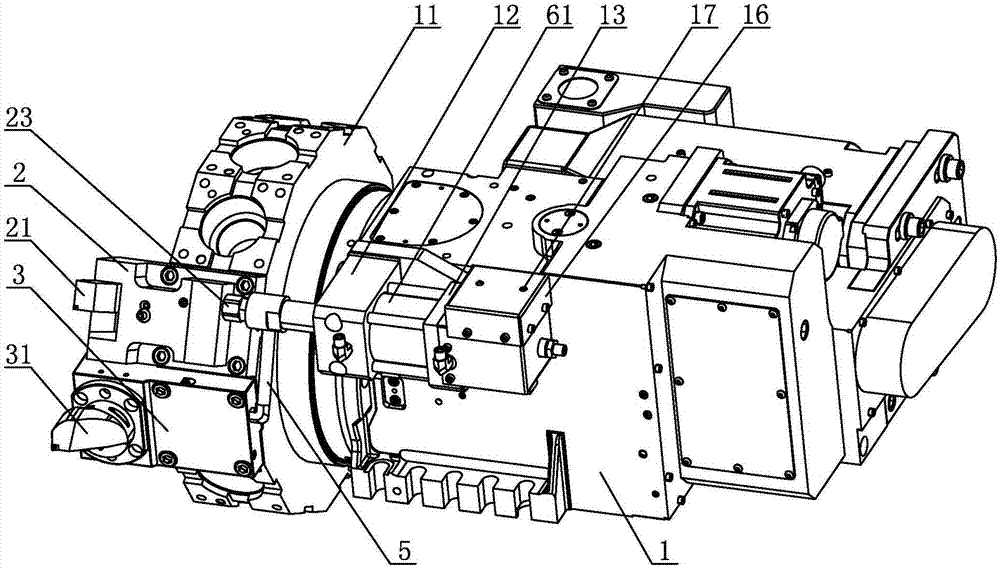

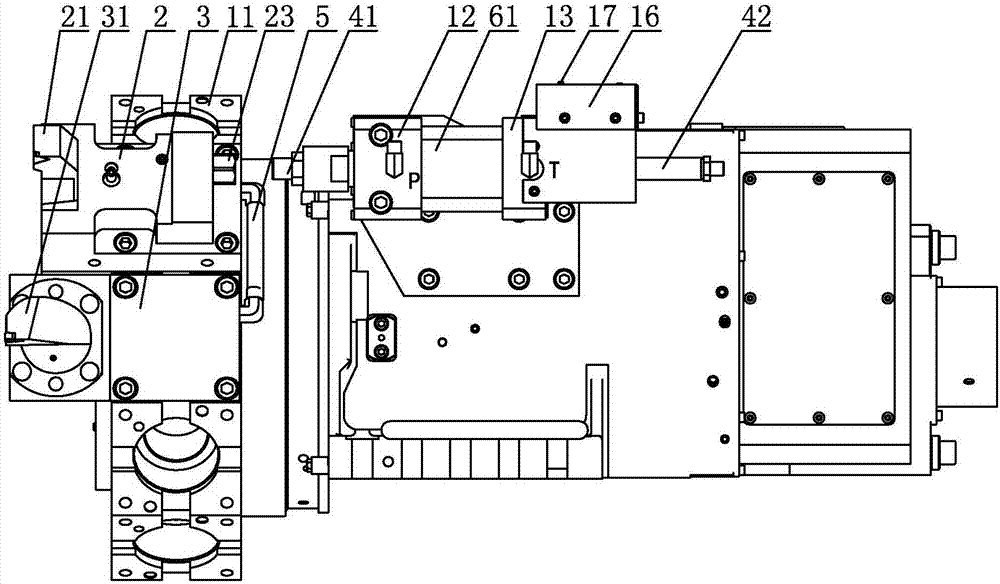

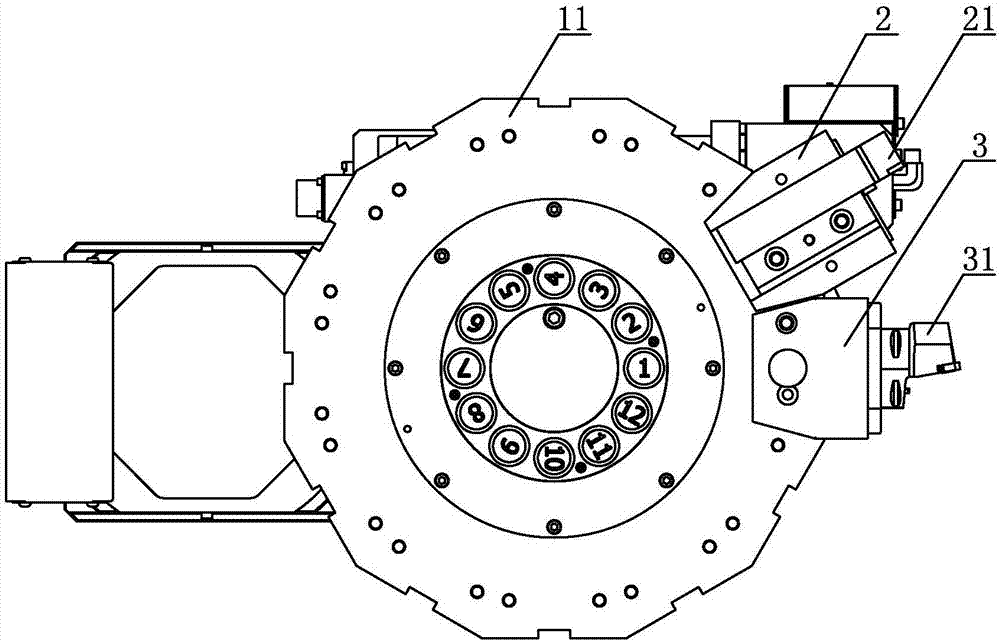

[0021] As shown in the figure, the CNC lathe high-pressure water outlet turret assembly of the embodiment 1 includes a turret 1, a first tool holder 2, a second tool holder 3 and a water delivery pipe 4. One end of the turret 1 is provided with a turret 11. A tool holder 2 and a second tool holder 3 are mounted on the cutter head 11 , the first cutter holder 2 is fitted with an outer cylindrical cutter 21 , the second cutter holder 3 is fitted with a thread cutter 31 , and the first cutter holder 2 is provided with a threaded cutter 31 . The first water channel 22 and the second water channel (not shown in the figure) are arranged in the second knife base 3, the water outlet of the first water channel 22 is connected with the water inlet of the second water channel through the steel pipe 5, and the water outlet of the second water channel It is connected with the central water outlet (not shown in the figure) of the thread cutter 31. The water inlet of the first water channel 2...

Embodiment 2

[0024]The structure of the high-pressure water outlet turret assembly of the CNC lathe in Embodiment 2 is basically the same as that of the turret assembly in Embodiment 1. The difference is that in Embodiment 2, the water pipe 4 is equipped with a limit position for the movement of the water pipe 4. As for the limiting block 44 , the protective cover 16 is installed on the second support base 13 , and the first proximity switch 17 and the second proximity switch 18 adapted to the limiting block 44 are installed on the protective cover 16 .

[0025] In the above embodiment 1 and embodiment 2, the second tool holder 3 is an outsourced standard thread turning tool holder, specifically a thread turning tool holder with a model number of C6-TRE-BT75A produced by Sandvik Company.

[0026] The high-pressure water outlet turret assembly of the numerical control lathe of the present invention can quickly realize the switching between the thread processing mode and the outer circle proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com