A high numerical aperture all-solid-state fluorotellurite glass optical fiber, preparation method and application thereof

A high numerical aperture, fluorotellurite technology, applied in glass manufacturing equipment, clad optical fiber, optics, etc., can solve the problems of increased fiber loss and shortened life of related devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of high NA all-solid-state fluorotellurite glass optical fiber

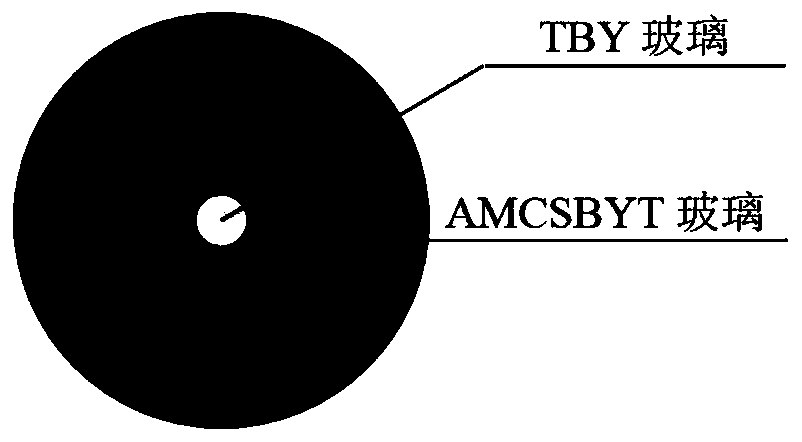

[0031] A high numerical aperture all-solid-state fluorotellurite glass fiber, such as figure 1As shown, including the core and cladding, wherein the material of the core is barium tellurium yttrium (TBY), the diameter of the core is 7 μm, which is made of TeO 2 、BaF 2 , Y 2 o 3 Composition, the mole percentage of each component is: TeO 2 70%, BaF 2 20%, Y 2 o 3 10%; the cladding material is aluminum magnesium calcium strontium barium yttrium tellurium (AMCSBYT), the thickness is 100μm, which is made of AlF 3 , MgF 2 , CaF 2 , SrF 2 、BaF 2 , YF 3 , TeO 2 Composition, the mole percentage of each component is: AlF 3 29%, MgF 2 9%, CaF 2 17%, SrF 2 8.5%, BaF 2 8.5%, YF 3 13%, TeO 2 10%;

[0032] A method for preparing a high numerical aperture all-solid-state fluorotellurite glass optical fiber, the specific steps are as follows:

[0033] (1) According to th...

Embodiment 2

[0036] Example 2: Application of preparation of high-NA all-solid-state fluorotellurite glass optical fiber in high-power supercontinuum light source

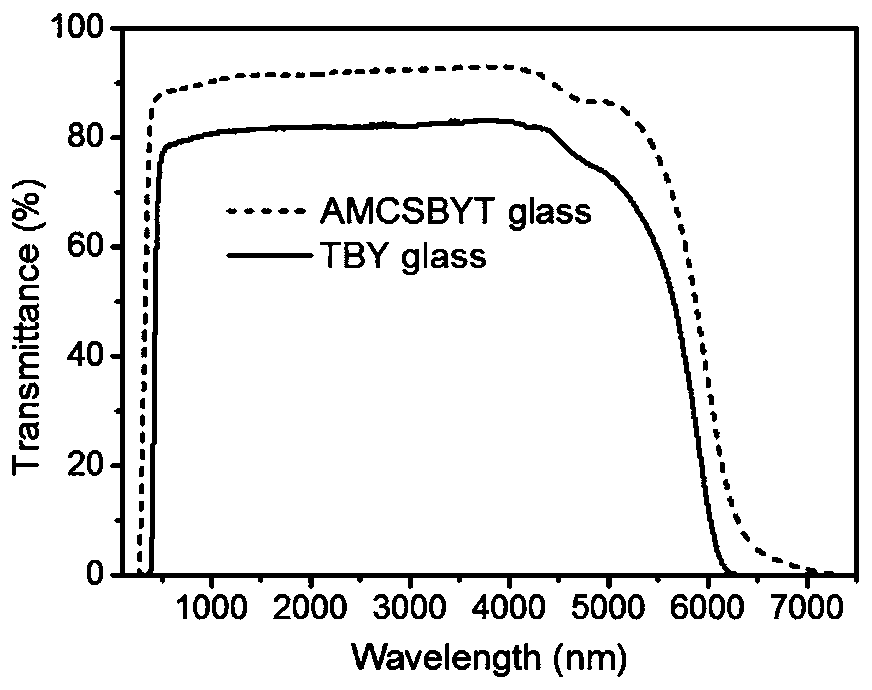

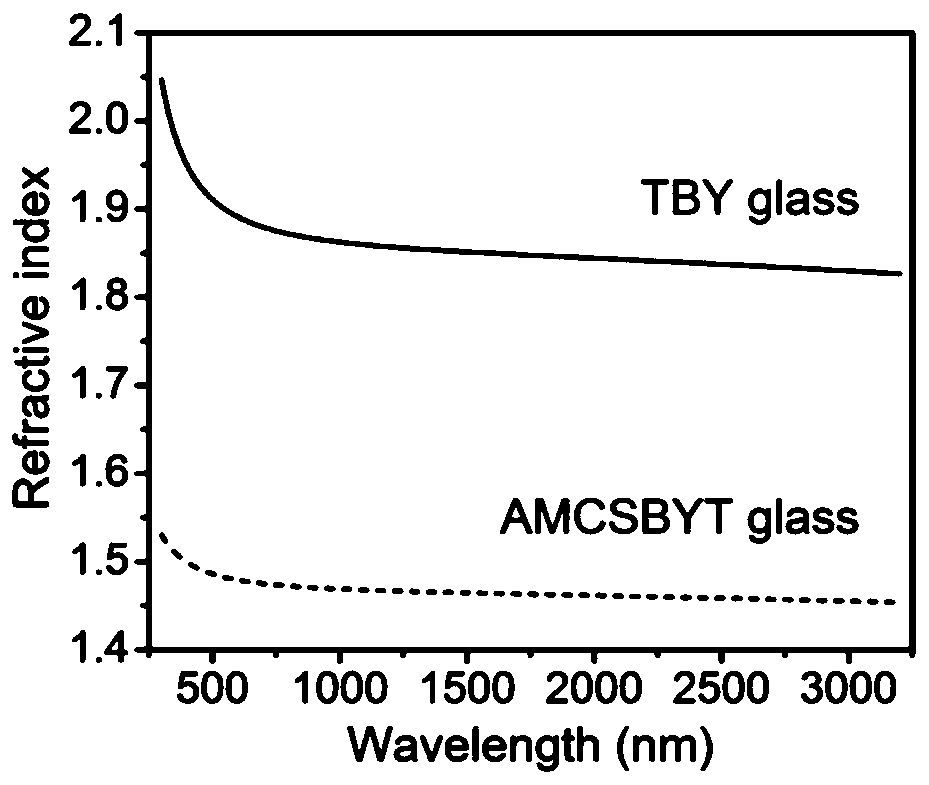

[0037] use Figure 7 The device shown is used to test the prepared ultra-high NA all-solid-state fluorotellurite glass optical fiber. The pump source 1 is a 2 μm femtosecond fiber laser. After the pump light passes through the isolator 2, it is coupled into the fluorotellurite glass fiber 4 prepared by us through the lens group 3. The final output spectrum and power are obtained by the spectrum analyzer 5 monitor. Due to the large difference in refractive index between the two component glasses (TBY glass: n=~1.84@2μm, AMCSBYT glass: n=~1.46@2μm), the calculated NA of the optical fiber at 2μm is ~1.1. In the experiment, we used a 60cm-long high-NA all-solid-state fluorotellurite glass fiber as the nonlinear medium. When the pump power was ~10.5W, we obtained a supercontinuum light source with an average power of 4.5W and a sp...

Embodiment 3

[0038] Example 3: Application of tapered high-NA all-solid-state fluorotellurite glass fiber in broadband supercontinuum light source

[0039] The ultra-high NA all-solid-state fluorotellurite glass optical fiber prepared in Example 1 was tapered with an optical fiber tapering machine. The taper length of the prepared tapered optical fiber is ~1.8 cm, and the core diameter of the optical fiber is reduced from 7 μm to 1.4 μm. Figure 9 The relationship between the core diameter and the position of the tapered fluorotellurite glass fiber we made is given, as well as the calculated group velocity dispersion curves of the fundamental mode in the fluorotellurite glass fiber with different core diameters. Using this tapered fluorotellurite glass fiber as a nonlinear medium, Figure 7 The device shown was used to test it. The pump source 1 is a 1.56 μm femtosecond fiber laser. After the pump light passes through the isolator 2, it is coupled into the tapered fluorotellurite glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com