Antibacterial nonwoven cloth and production method thereof

A non-woven fabric and antibacterial adhesive technology, which is applied in the direction of non-woven fabrics, textiles, and papermaking, can solve the problems of general antibacterial effect, weakened antibacterial effect, and single antibacterial particles, and achieve good dimensional stability, easy post-processing, The effect of less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

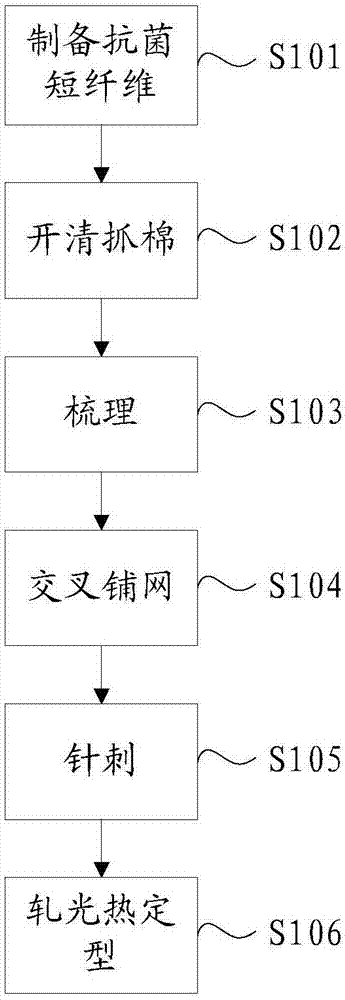

[0024] A kind of preparation method of antibacterial nonwoven fabric is provided in the present embodiment, such as figure 1 As shown, it has the following steps:

[0025] S101: preparing antibacterial fibers;

[0026] Preparation of antibacterial polypropylene staple fiber and antibacterial polyester staple fiber: mix one or more of the three antibacterial particles of nano-bamboo carbon, nano-zinc and silver ions to make masterbatch, and then heat-melt the masterbatch with polypropylene and polyester respectively Mixed, and then spun into antibacterial polypropylene staple fiber and antibacterial polyester staple fiber through spinning process. Wherein, the addition amount of the master batch that contains three kinds of bacteriostatic particles of nano bamboo carbon, nano zinc and silver ion is 2%~5% (master batch accounts for 2%~5% of mixing total amount, 2%~5% is The optimal content obtained in long-term production practice, the antibacterial polyester staple fiber with...

Embodiment 2

[0048] This example provides an antibacterial nonwoven fabric, which is prepared by the preparation method of the first embodiment above.

[0049] The antibacterial nonwoven fabric is made of two or three kinds of antibacterial polypropylene staple fibers, antibacterial polyester staple fibers, and antibacterial viscose staple fibers. Both antibacterial polypropylene staple fibers and antibacterial polyester staple fibers contain antibacterial and deodorizing nano-bamboo carbon One or more of the three kinds of antibacterial particles, nano-zinc and silver ions, so that the antibacterial nonwoven fabric made of a variety of fibers has the function of antibacterial and deodorizing, and is isotropic, stable in size, not easy to deform, Wear-resistant and stretchable, it can be used to make the lining of furniture commonly used by the human body such as cushions and sofas. It has a wide range of uses and can be used for a long time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com