Device and method for detecting characteristic frequency of motor vibration

A characteristic frequency and detection device technology, which is applied to the detection of motor vibration characteristic frequency and the field of motor vibration characteristic frequency detection device, can solve the problems of inability to obtain equipment characteristic frequency and complex structure, and achieve low test cost, good repeatability, The effect of separating fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings of the specification:

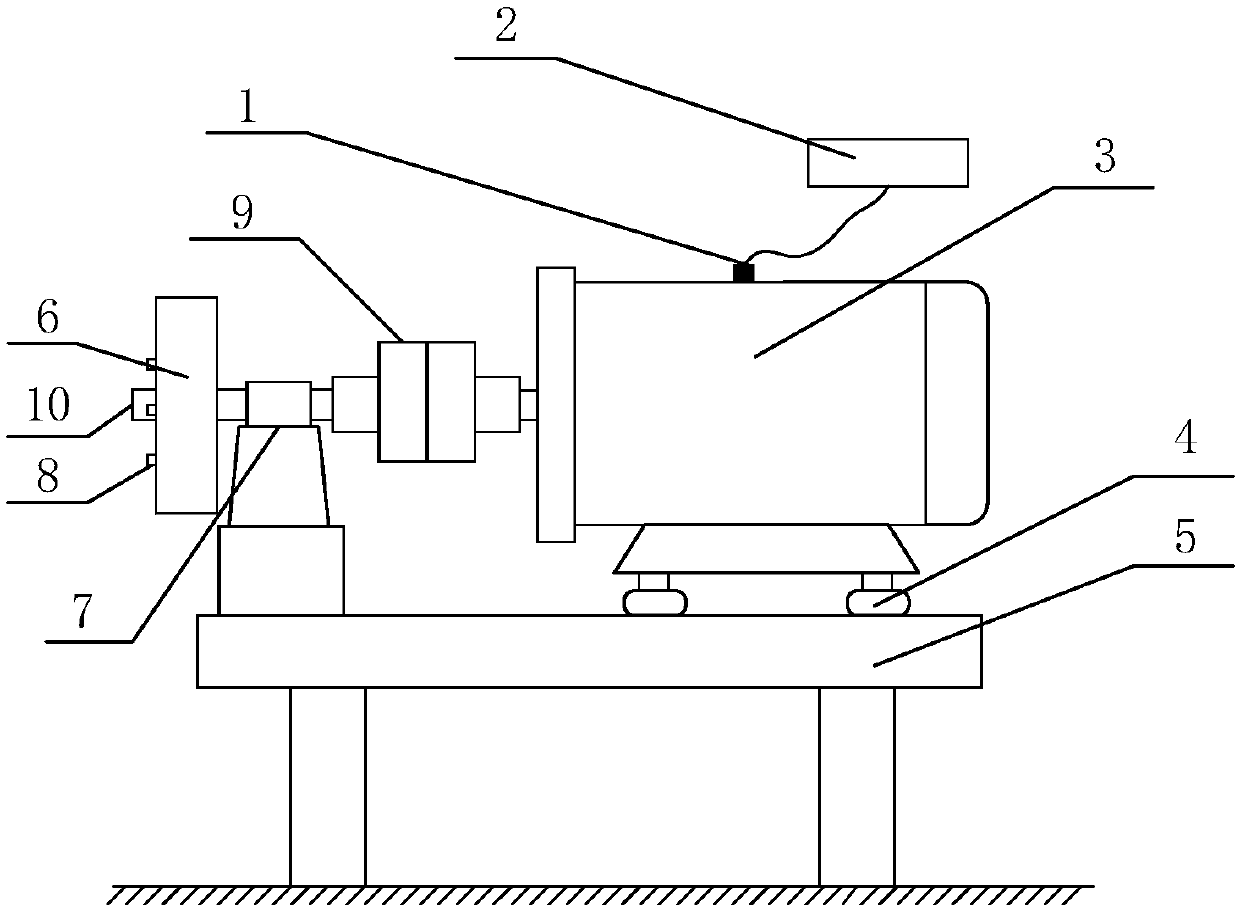

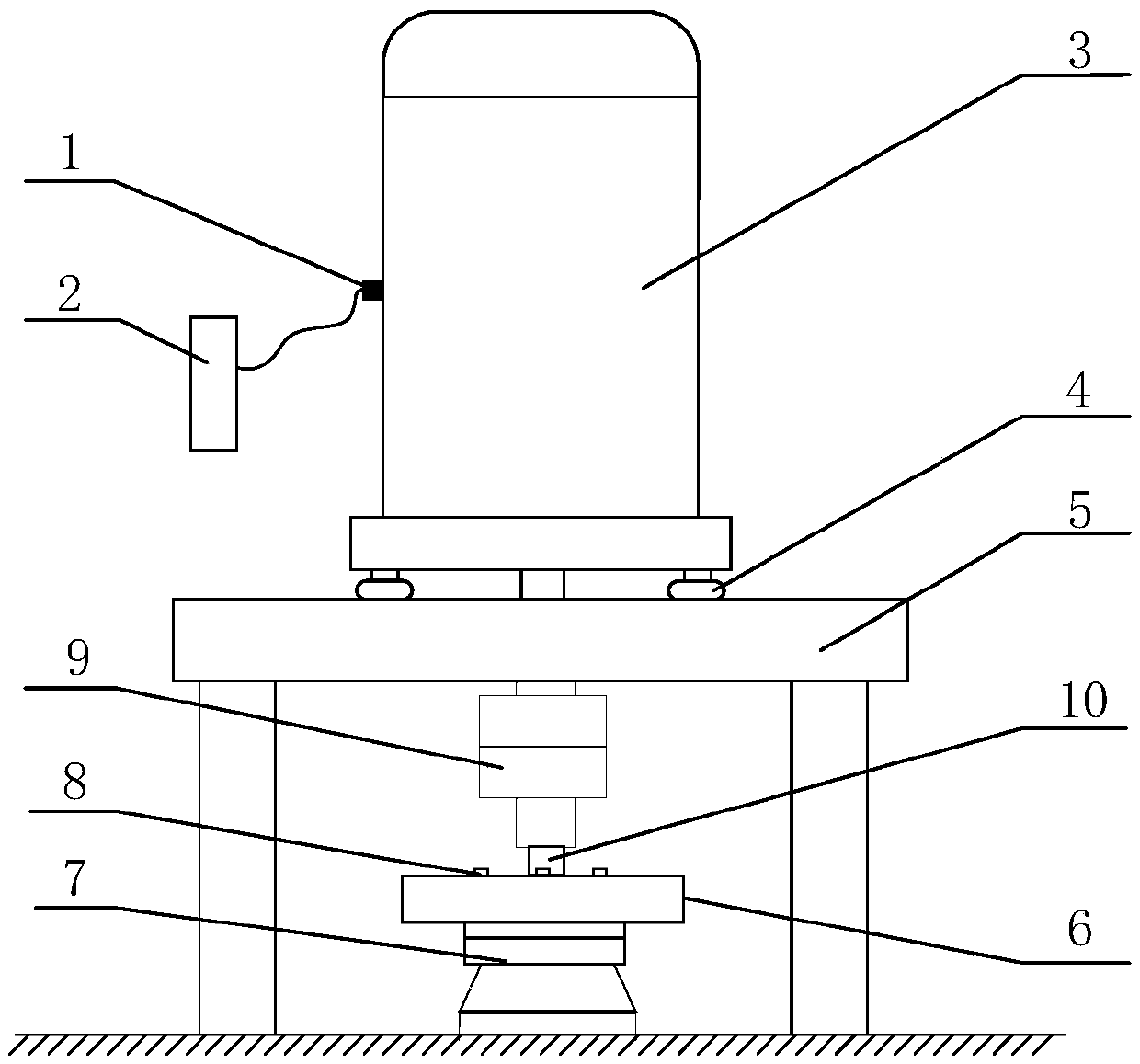

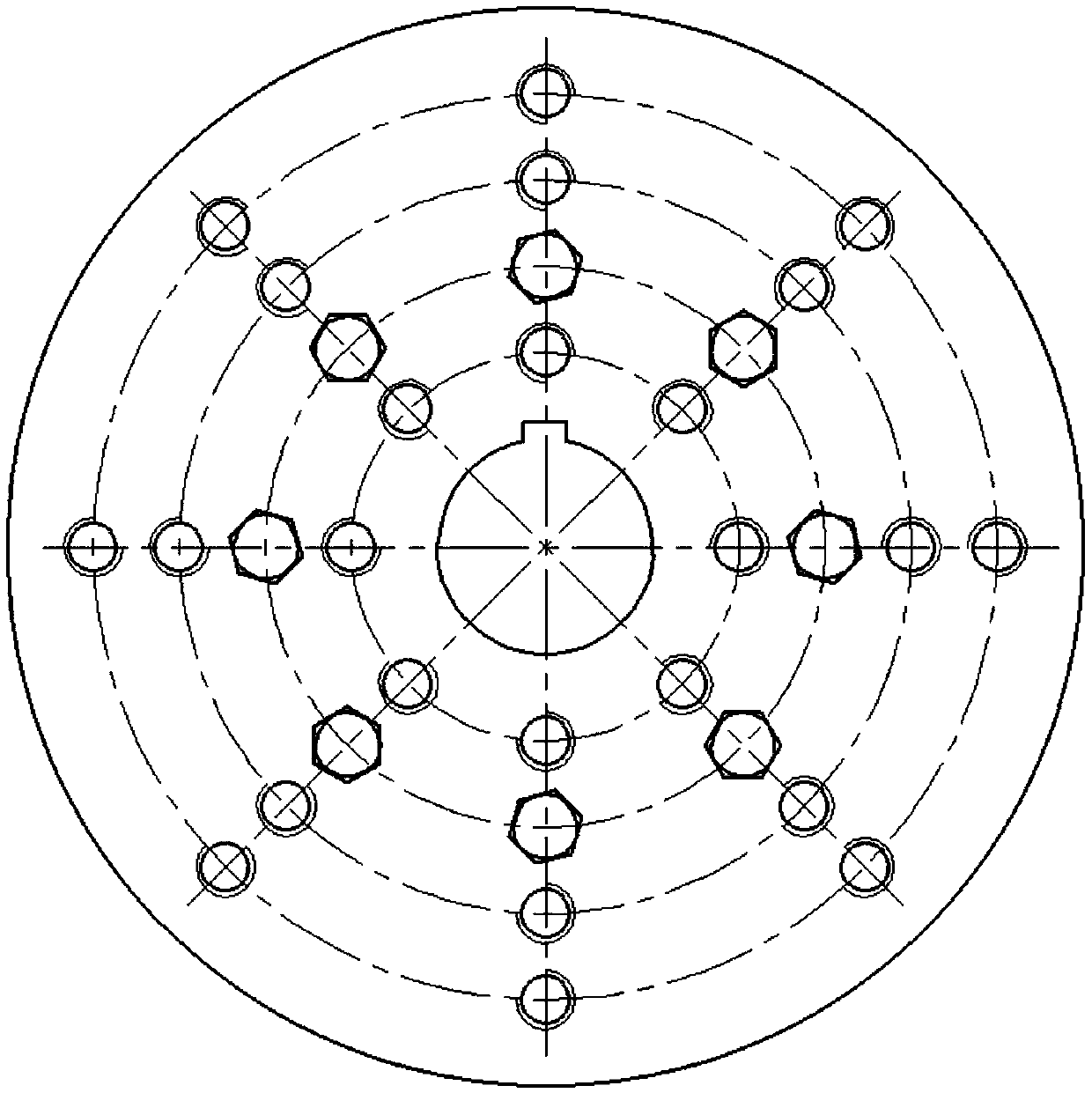

[0023] The device of the present invention includes a mounting base 5, a vibration isolator 4, a flywheel 6, an air bearing 7, an elastic coupling 9, an acceleration sensor 1, and a vibration test analyzer 2 to realize the measurement of the characteristic frequency of the motor 3. The following two specific implementation technical solutions are given for horizontal installation and vertical installation of the motor:

[0024] Technical Solution One:

[0025] Such as figure 1 As shown, a detection device for motor vibration characteristic frequency of the present invention includes the mounting flange of the motor 3 horizontally mounted on the mounting base 5 through the vibration isolator 4, the mounting base 5 is placed horizontally, and the upper surface is also in a horizontal state, In order to reduce the influence of the base on the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com