Automatic tester for static compressive strength elasticity modulus of concrete

A technology of static compression and elastic modulus, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., it can solve the problems of difficult data reading and complex data calculation, and achieve simple measurement and positioning , Improve test efficiency, improve the effect of success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

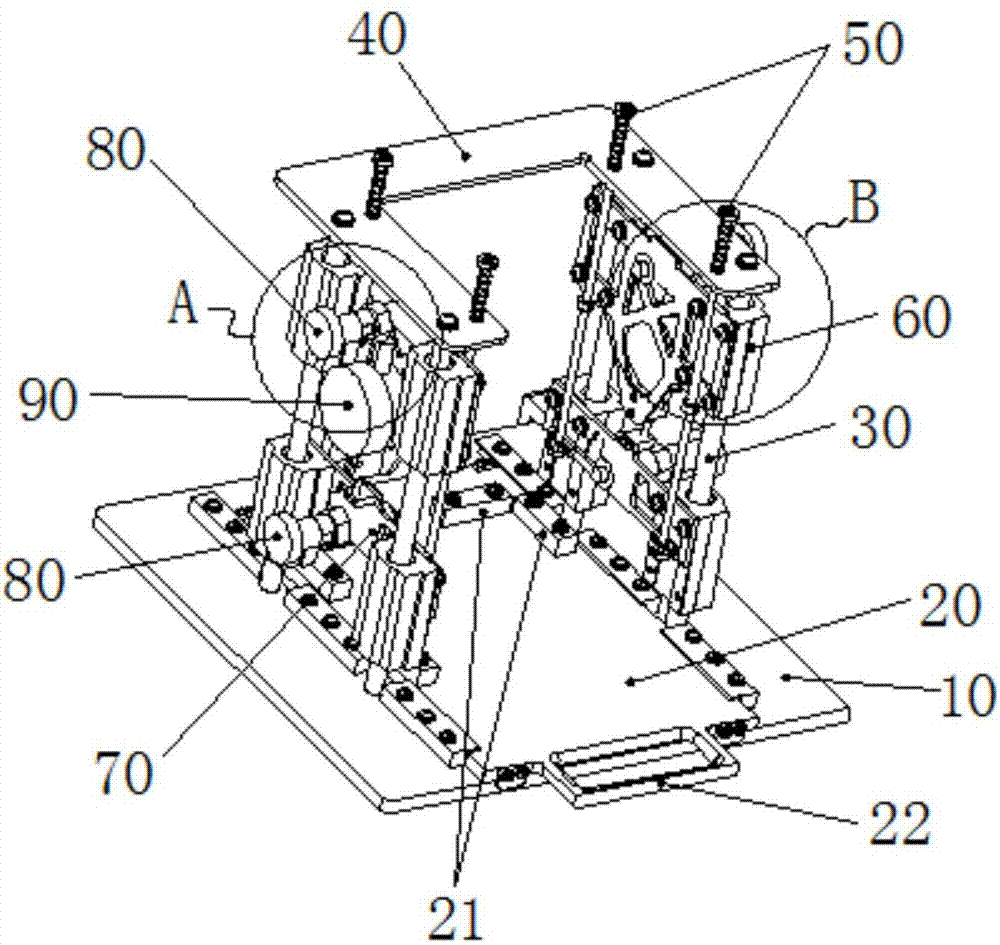

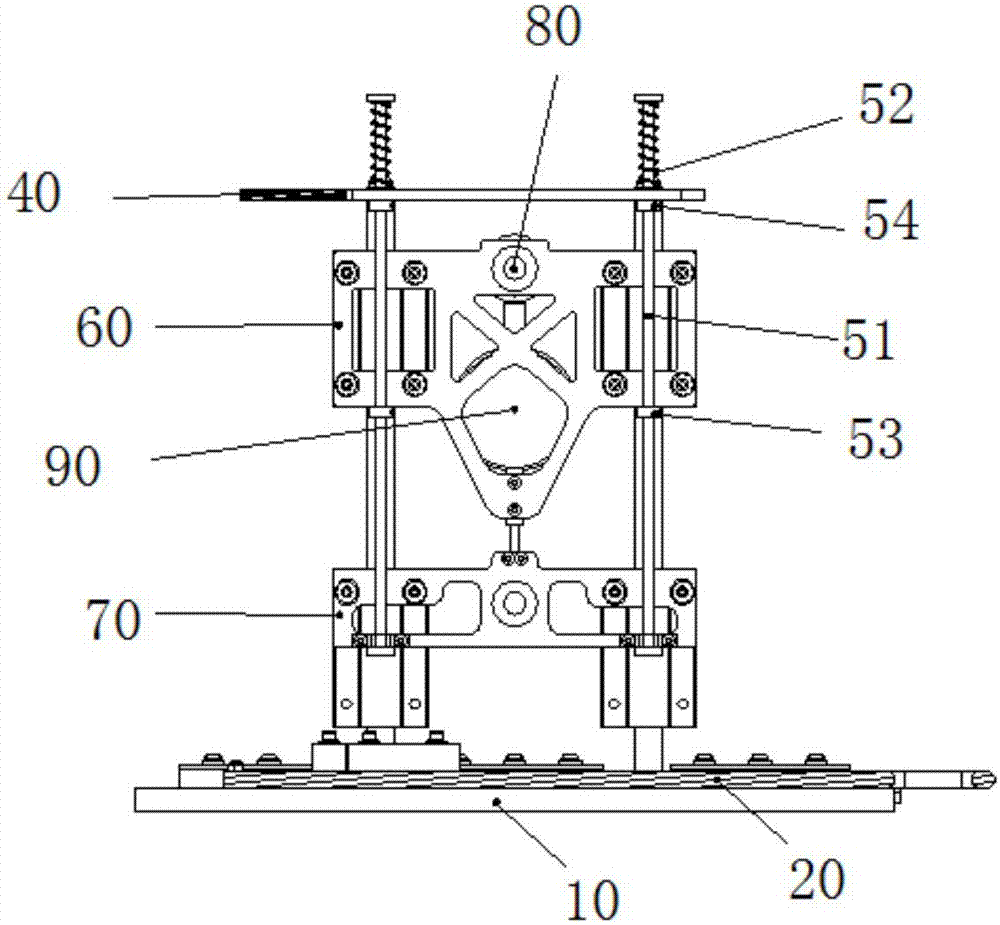

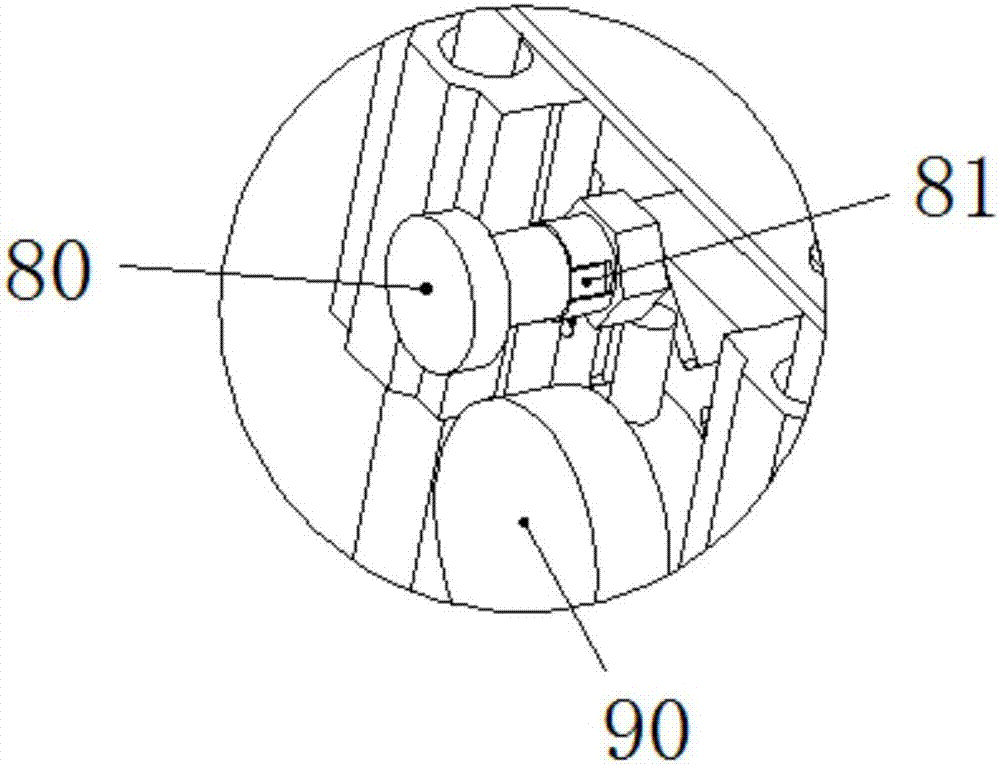

[0026] Such as Figure 1-5 As shown, a concrete static compression elastic modulus automatic measuring instrument includes a horizontal bottom plate 10, an upper strain measurement assembly 60, a lower strain measurement assembly 70, a top plate 40, a dial indicator 90 and a digital display. A test piece positioning plate 20 and four vertical slide bars 30 are installed on the bottom plate 10 , and the four slide bars 30 are symmetrically arranged on the left and right sides of the test piece positioning plate 20 . The bottom plate 10 is provided with linear track grooves on the left and right sides of the test piece positioning plate 20, and the left and right ends of the test piece positioning plate 20 are correspondingly located in the track grooves and can slide along the track grooves. The upper surface of the test piece positioning plate 20 is provided with a test piece positioning block 21 , and the front end is fixedly provided with a handle 22 and a blocking plate, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com