A device and method for preventing medium and low voltage cable armor from leaking

A low-voltage cable and armoring technology, which is used in the field of cable production control and steel tape armoring machine wrapping quality control, can solve the problems of cable conductor thinning and breaking, cable core insulation damage, steel tape leakage, etc. Yield rate, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

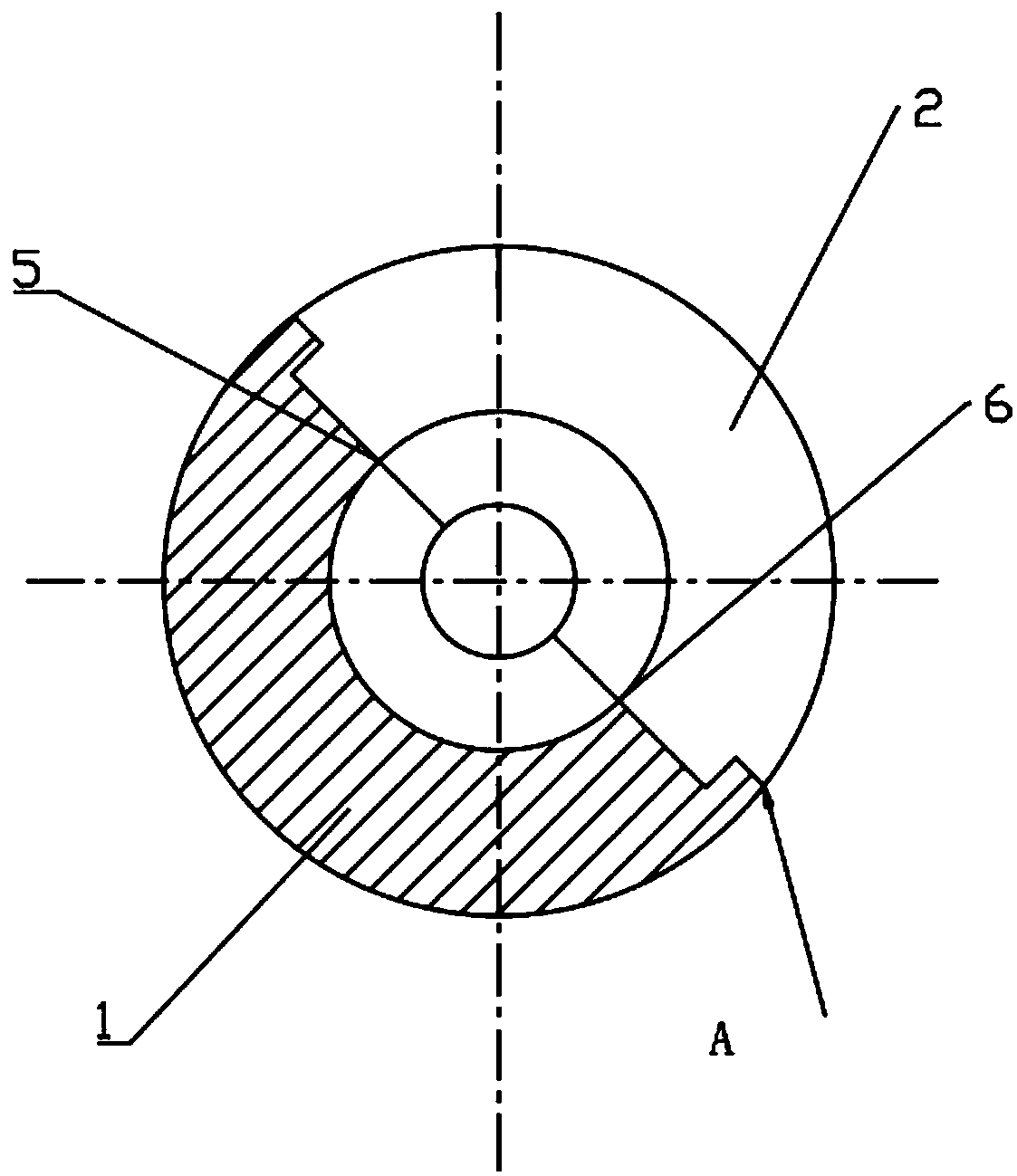

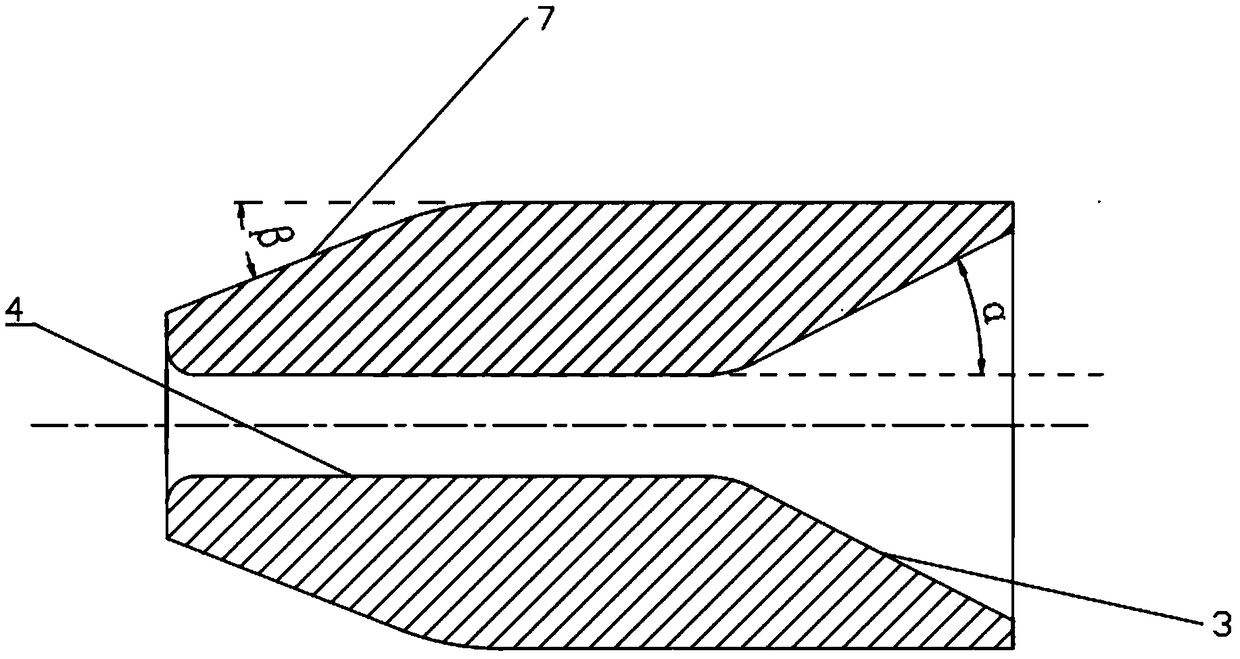

[0021] Such as Figure 1 to Figure 2 As shown, taking the processing of a cable with a diameter of 15mm as an example, a device specially used to prevent leakage of medium and low voltage cable armor, the diameter of the wire passing die is set to 80mm, and the wire passing die includes the first mold 1 and the The second mold 2, the first mold 1 and the second mold 2 have mutually symmetrical cable inlet grooves 3, the length of the cable inlet groove 3 is set to 50mm, the cable inlet groove 3 is set as a cone, and the cone angle α is set The end of the cable inlet groove 3 is smoothly connected with the diameter bearing groove 4, the length of the diameter bearing groove 4 is set to 100mm, the diameter of the diameter bearing groove 4 is set to 18mm, and the front end 7 of the wire passing mold is set as a cone with a length of 50mm shape, the angle β of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com