Low-efficiency and low-consumption water seal lithium ion battery film extraction process

A lithium-ion battery, low water consumption technology, applied in solvent extraction, countercurrent extraction, battery pack components, etc., can solve the impact of extraction concentration and extraction activity, increase the difficulty of extractant treatment, and consume large amounts of dichloromethane, etc. problems, achieve good economic benefits and production requirements, increase extraction activity, and reduce volatilization consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Adopt dichloromethane as extraction agent

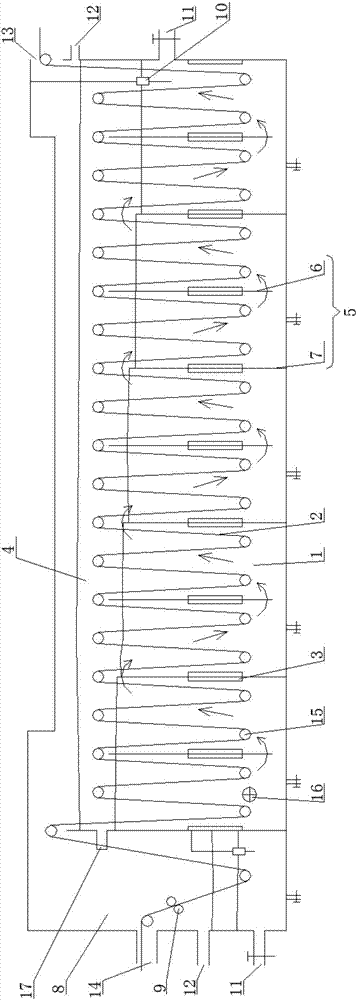

[0037] A high-efficiency and low-consumption water-sealed lithium-ion battery film extraction process, the battery film is placed in the extraction equipment equipped with dichloromethane for extraction, the extraction equipment includes a closed extraction tank storing dichloromethane 1, setting Guide roller 15 for transporting the film 2 in the extraction tank 1, and the dichloromethane heating device 3, the film 2 is submerged in the dichloromethane to replace the small molecule agent (pore-forming agent) therein, in the dichloromethane extractant The upper layer is also provided with a water seal layer 4, which adopts a flowing water seal layer, water is continuously introduced and drawn out through overflow, and the temperature of the water seal layer is controlled below 36°C. A set of upper and lower Separators 5 are arranged in random order, and a serpentine dichloromethane extractant circulation channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com