High-rebound-elasticity warm non-woven fabric

A technology of resilience and non-woven fabrics, applied in the field of high resilience non-woven fabrics for thermal insulation, can solve the problems of heavy weight and unsatisfactory rebound effect, and achieve the effects of light weight, improved fluffing phenomenon, and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

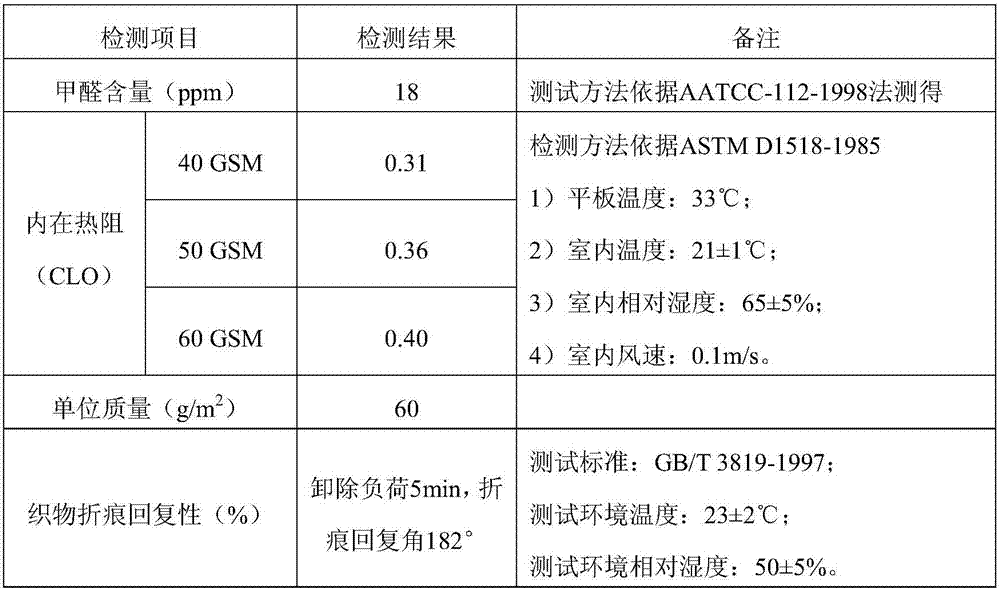

[0019] This example is a high-resilience thermal non-woven fabric, which uses hollow fibers and special-shaped fibers as base materials, and uses environmentally friendly resins with extremely low formaldehyde content and low glass transition temperature as adhesives. It has light weight, good bulkiness, It has the characteristics of high resilience, softness and warmth retention. The products of this embodiment are generally more used in the cuffs of jackets and access control.

[0020] This embodiment is a high resilience thermal non-woven fabric, and its preparation process comprises the following steps:

[0021] 1) Select the base material: select hollow fiber and special-shaped fiber as the base material, and the hollow fiber contains 15-25% of 3D crimped fiber, 65-75% of 1.5D crimped fiber and 5-15% of special-shaped fiber;

[0022] 2) Substrate treatment: it includes,

[0023] A. Substrate mixing: put the whole package of the hollow fiber and the shaped fiber into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com