Open area core with chopped fiber reinforced skin

一种纤维、玻璃纤维的技术,应用在中空结构芯支撑基质领域,能够解决低总密度、夹层复合材料热循环性能不是最佳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

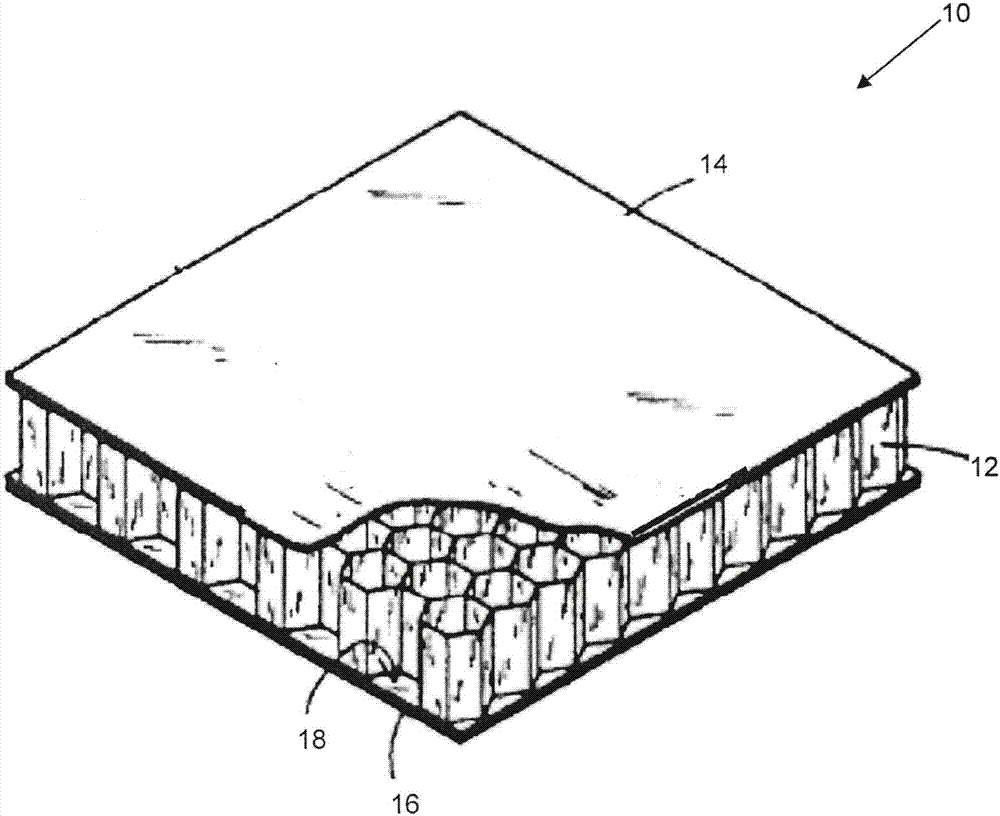

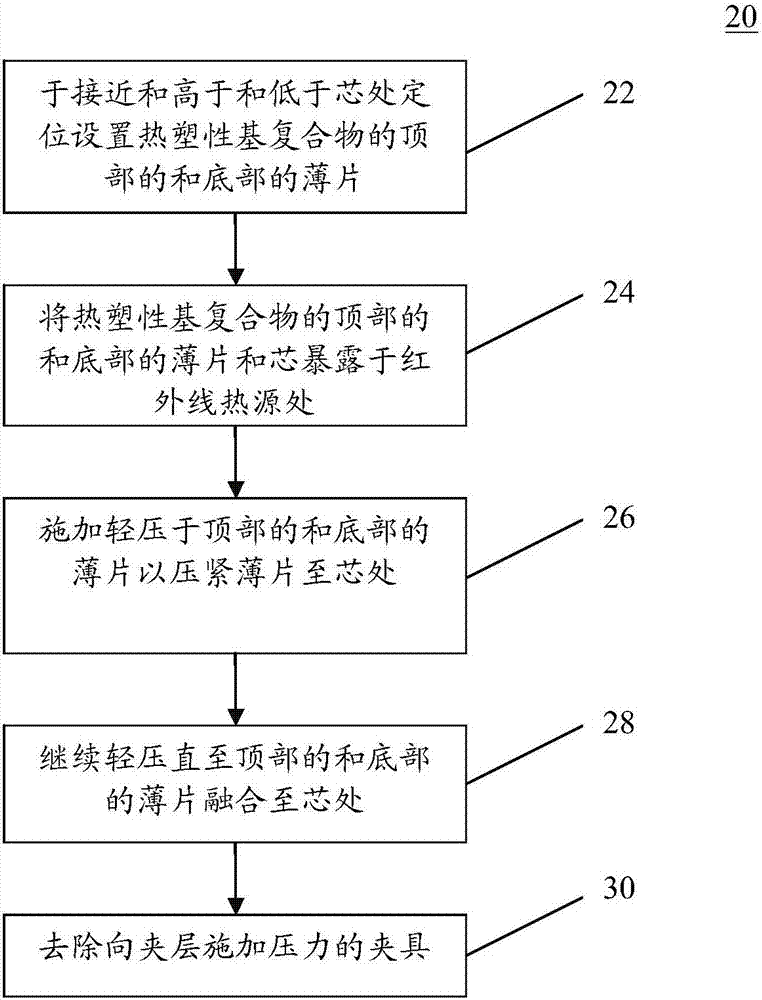

[0010] The present invention has utility as an improved composite sandwich panel structure having two side sheets sandwiching an intermediate hollow structural core support matrix made of the same composite material as the top and bottom sheets to improve Thermal cycle performance and relief of formed part stress. The sandwich composite structure of the embodiment of the present invention is made of polypropylene, nylon, polycarbonate, polyethylene, acrylonitrile butadiene styrene (acrylonitrile butadienestyrene), polybutene, cross-linked polyethylene (polyethylene cross linked), poly Vinyl chloride, chlorinated polyvinyl chloride, polyvinylidene fluoride, and thermoplastic polymers containing any of the above block copolymers (block copolymers).

[0011] As used in the present invention, the term "same" applied to a type of polymer is intended to mean that there is a common monomeric subunit present in the majority in both polymers. It will be appreciated that some, but not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com