Local annealing method and annealing device for rivet cover of high-temperature alloy self-plugging rivet

A high-temperature alloy steel and blind rivet technology, applied in the direction of improving energy efficiency, process efficiency, furnace type, etc., can solve the problem of small volume and effective heating area of blind rivet sleeves, inaccurate heat treatment process control, and insufficient To local heat treatment and other issues, achieve the effect of improving the quality of the nail sleeve, improving the level of manufacturing technology and manufacturing efficiency, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

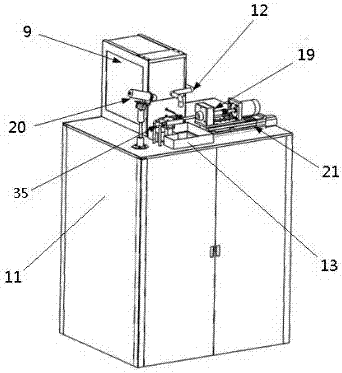

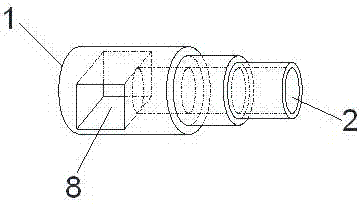

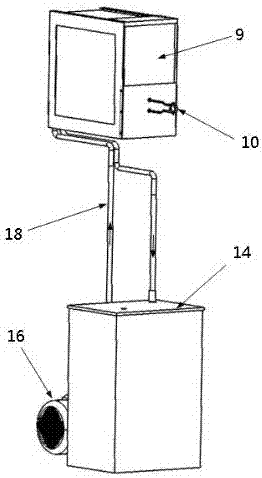

[0047] Example. A method for local annealing of high-temperature alloy steel blind rivet sleeves, such as Figure 1 to Figure 9 As shown, the method is to anneal the nail sleeve locally by making the nail sleeve form a temperature field with a temperature gradient during the heating process; the method is to form a temperature gradient with a temperature gradient in the annealing zone of the nail sleeve during the heating process field, annealing the annealing zone; the method is to heat the annealing zone of the nail sleeve through the heating system 9 and the auxiliary heating sleeve, so that the annealing zone forms a temperature field with a temperature gradient during the heating process, and anneals the annealing zone; The method is to set an inner hole 2 with a gradient wall thickness in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com