Ti2 AlNb-based alloy and gamma-TiAl-based alloy dissimilar material brazing postweld heat treatment process

A post-heat treatment, base alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem that the heat treatment system is not suitable for brazing joints, melting, reducing residual stress of welding joints, etc., to improve the efficiency of heat treatment work , Improve the tensile strength, optimize the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

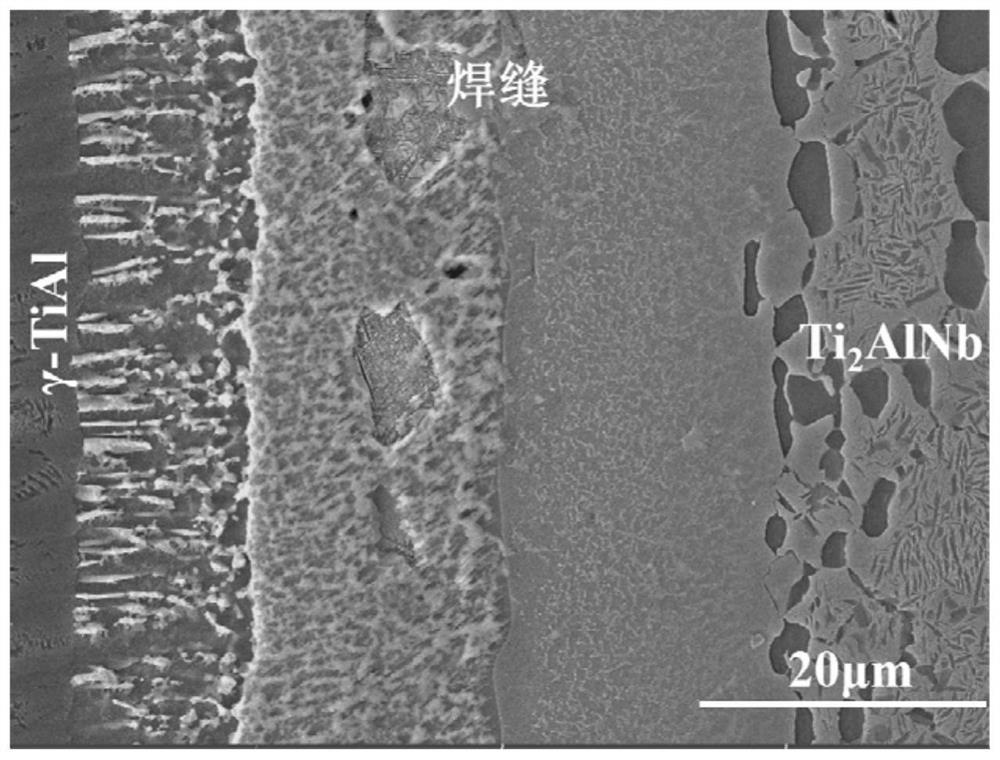

[0038] In this example, the Ti 2 AlNb-based alloys and γ-TiAl-based alloys are welded by vacuum brazing, Ti 2 The post-weld heat treatment process of AlNb-based alloy and γ-TiAl-based alloy dissimilar brazing is as follows:

[0039] Put the brazed sample into a vacuum heat treatment furnace and heat it up to 680°C with the furnace, keep it warm for 15 minutes, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; then heat up to the heat treatment temperature of 720°C, keep it warm for 3h, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; cooled to room temperature with the furnace.

[0040] figure 2 It is the microstructure of the brazed joint after heat treatment at 720°C / 3h, and the tensile strength of the brazed joint at this time is 475MPa. This heat treatment process optimizes the microstructure of the brazed joint and improves its mechanical properties.

Embodiment 2

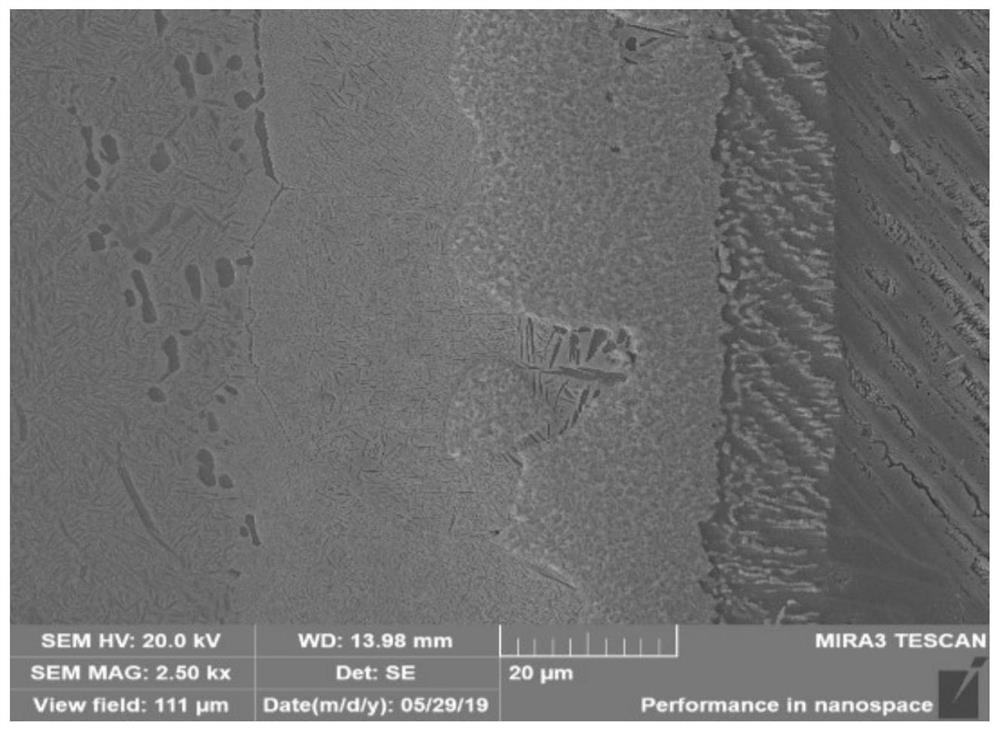

[0042] In this example, the Ti 2 AlNb-based alloys and γ-TiAl-based alloys are welded by vacuum brazing, Ti 2 The post-weld heat treatment process of AlNb-based alloy and γ-TiAl-based alloy dissimilar brazing is as follows:

[0043] Put the brazed sample into a vacuum heat treatment furnace and heat it up to 700°C with the furnace, keep it warm for 15 minutes, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; then heat up to a heat treatment temperature of 750°C, keep warm for 3 hours, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; cooled to room temperature with the furnace.

[0044] image 3 It is the microstructure of the brazed joint after heat treatment at 750°C / 3h, and the tensile strength of the brazed joint at this time is 440MPa. This heat treatment process optimizes the microstructure of the brazed joint and improves its mechanical properties.

Embodiment 3

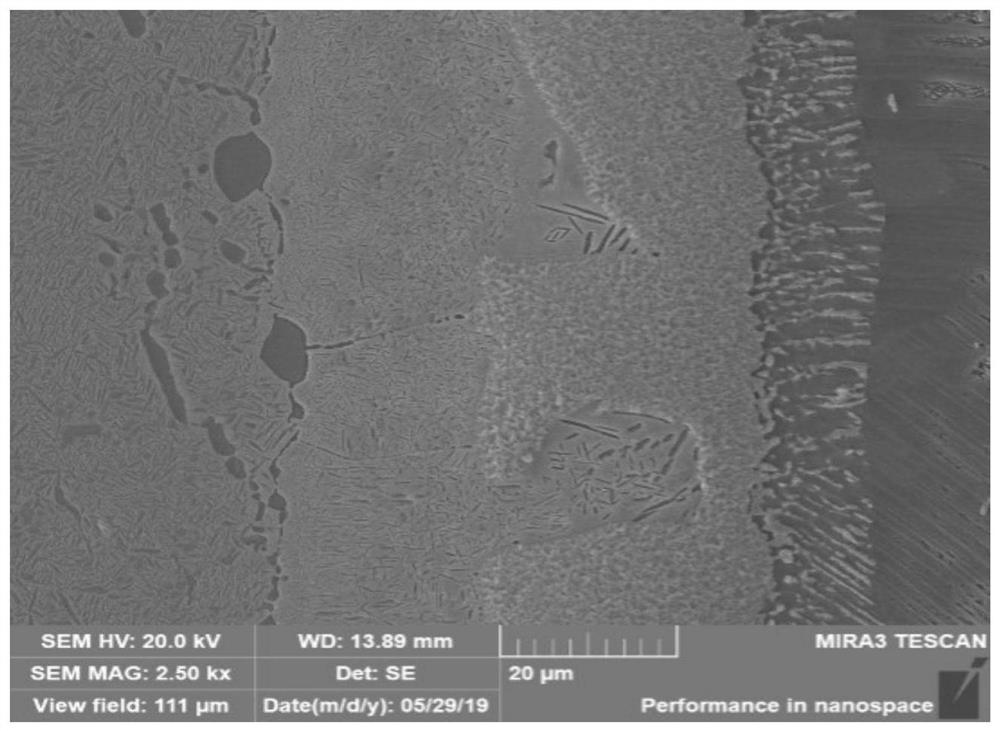

[0046] In this example, the Ti 2 AlNb-based alloys and γ-TiAl-based alloys are welded by vacuum brazing, Ti 2 The post-weld heat treatment process of AlNb-based alloy and γ-TiAl-based alloy dissimilar brazing is as follows:

[0047] Put the brazed sample into a vacuum heat treatment furnace and heat it up to 680°C with the furnace, keep it warm for 15 minutes, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; then heat up to a heat treatment temperature of 700°C, keep warm for 5h, and the vacuum degree is: 5×10 -3 ~5×10 -4 Pa; cooled to room temperature with the furnace.

[0048] Figure 4 It is the microstructure of the brazed joint after heat treatment at 700°C / 5h, and the tensile strength of the brazed joint at this time is 450MPa. This heat treatment process optimizes the microstructure of the brazed joint and improves its mechanical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com