A retention aid for papermaking

A retention aid and quality technology, applied in the field of papermaking additives, can solve the problems of loose pulp fiber structure, weak fiber adsorption, poor flatness, etc., to improve the retention rate, increase the number of contact points, and increase the retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

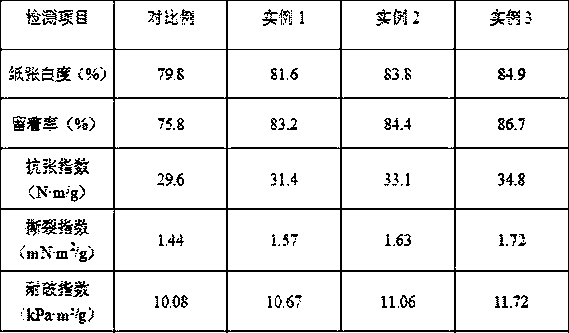

Examples

example 1

[0028] Collect the peach gum on the peach tree, put it in an oven, dry it at 70°C for 10 hours, crush it after drying, and pass it through a 80-mesh sieve to obtain peach gum powder. Add the peach gum powder into water at a mass ratio of 1:20, and soak it at room temperature After 8 hours, heat to 90°C, heat and stir for 20 minutes, then filter while it is hot, collect the filtrate, weigh the cotton stalks, cut them into 2cm pieces, put them in an oven, dry them at 105°C to constant weight, and place the dried cotton stalks In a steam heater, heat it to 130°C and keep it warm for 1 hour. After naturally cooling to room temperature, take out the material in the steam heater, add the material in the steam heater to the filtrate according to the mass ratio of 1:3, and add 0.3% of the filtrate mass N-methylolacrylamide, heated to 50°C, stirred and reacted for 4h, cooled to room temperature, filtered, collected filter residue, sprayed and frozen with liquid nitrogen for 30s, then pu...

example 2

[0031]Collect peach gum from peach trees, put it in an oven, dry at 75°C for 11 hours, crush it after drying, and pass through a 90-mesh sieve to obtain peach gum powder. Add the peach gum powder to water at a mass ratio of 1:20, and soak at room temperature After 9 hours, heat to 93°C, heat and stir for 25 minutes, then filter while it is hot, collect the filtrate, weigh the cotton stalks, cut them into 3cm pieces, put them in an oven, and dry them at 106°C to constant weight. In a steam heater, heat it to 135°C and keep it warm for 1 hour. After naturally cooling to room temperature, take out the material in the steam heater, and add the material in the steam heater to the filtrate according to the mass ratio of 1:3, and add 0.4% of the filtrate mass N-Methylolacrylamide, heated to 55°C, stirred for 5 hours, cooled to room temperature, filtered, collected filter residue, sprayed with liquid nitrogen and frozen for 35 seconds, then put it into a ceramic mortar grinder, at 90r / ...

example 3

[0034] Collect peach gum from peach trees, put it in an oven, dry at 80°C for 12 hours, crush it after drying, and pass through a 100-mesh sieve to obtain peach gum powder. Add the peach gum powder to water at a mass ratio of 1:20, and soak at room temperature After 10 hours, heat to 95°C, heat and stir for 30 minutes, then filter while it is hot, collect the filtrate, weigh the cotton stalks, cut them into 4cm pieces, put them in an oven, dry them at 108°C to constant weight, and place the dried cotton stalks In a steam heater, heat it to 140°C and keep it warm for 2 hours. After naturally cooling to room temperature, take out the material in the steam heater, and add the material in the steam heater to the filtrate according to the mass ratio of 1:3, and add 0.5% of the filtrate mass N-methylolacrylamide, heated to 60°C, stirred for 6 hours, cooled to room temperature, filtered, collected filter residue, sprayed with liquid nitrogen and frozen for 40 seconds, then put it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com