Steel structure assembled type building component and steel structure assembled type building

A building component and assembly technology, which is applied in the direction of building construction and construction, can solve the problems of poor structural stability, poor ability to resist natural disasters, poor thermal insulation ability, etc., and achieve fast assembly speed, good stability, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

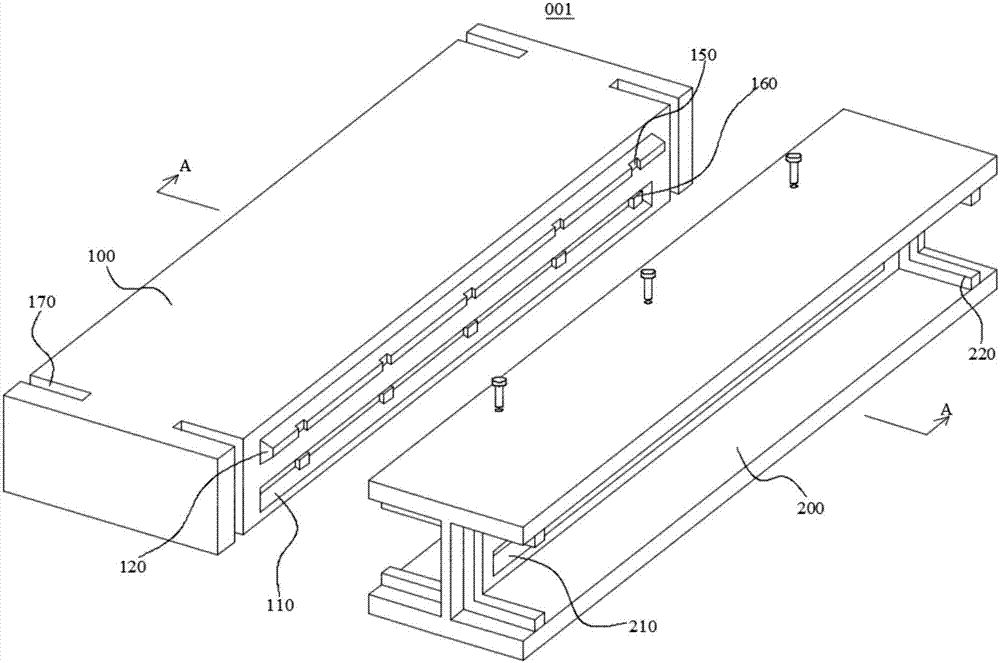

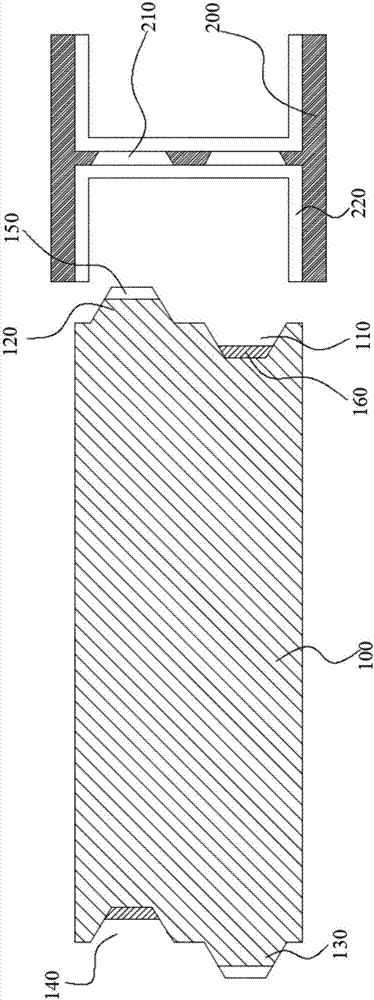

[0031] Please refer to figure 1 and figure 2 , this embodiment provides a prefabricated steel structure building assembly 001, which includes a prefabricated panel 100 and an I-beam connecting plate 200 clamped to one side of the prefabricated panel 100, and the prefabricated panel 100 and the I-beam connecting plate 200 are clamped One side is provided with at least one first card slot 110 and at least one first protrusion 120 extending along its length direction, and the other side is provided with a second protrusion 130 that can be engaged with the first card slot 110 and can be engaged with the first card slot 110. The second clamping groove 140 in which a protrusion 120 is clamped, and the I-beam connecting plate 200 is provided with a clamping hole 210 corresponding to the first protrusion 120 and the second protrusion 130 . In this embodiment, a first slot 110 and a first protrusion 120 are provided on both sides of the prefabricated panel 100 respectively. A straig...

Embodiment 2

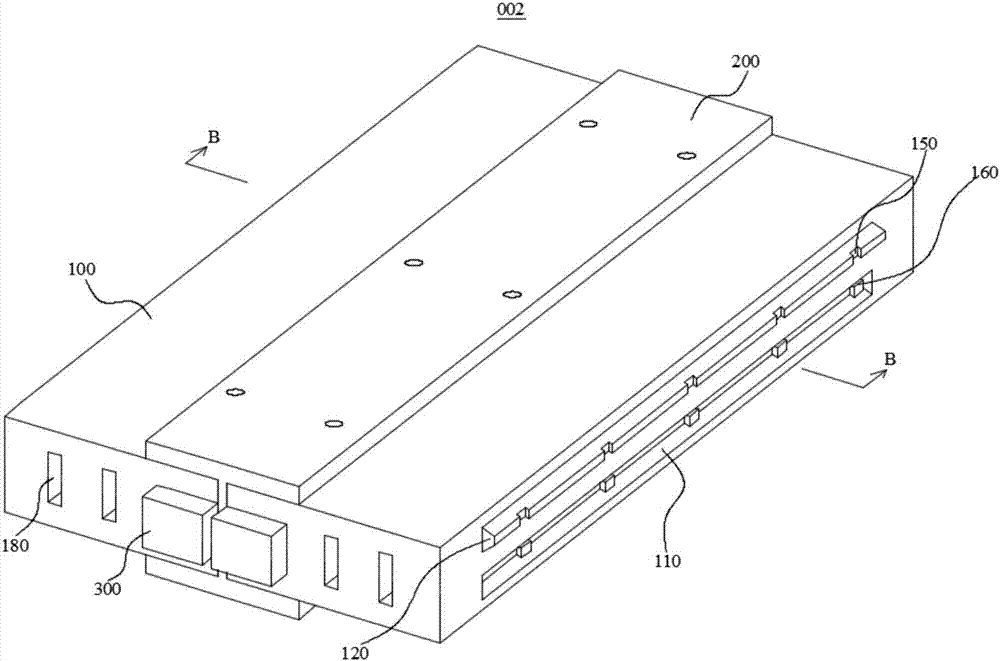

[0038] Please refer to image 3 , Figure 4 and Figure 5 As shown, this embodiment provides a steel structure prefabricated building, which includes a plurality of steel structure prefabricated building components 002, each steel structure prefabricated building component 002 includes a prefabricated panel 100 and is clamped with one side of the prefabricated panel 100 The I-beam connecting plate 200, the side where the prefabricated plate 100 is clamped with the I-beam connecting plate 200 is provided with a first slot 110 and a first protrusion 120 extending along its length direction, and the other side is provided with The second lug 130 that can be engaged with the first lug 110 and the second lug 140 that can be engaged with the first lug 120. The I-beam connecting plate 200 is provided with the first lug 120 and the second lug. In the engaging hole 210 corresponding to the protrusion 130, the first protrusion 120 and the second protrusion 130 are provided with three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com