Heat exchanger with multi-stream wound-tube-type shell sides

A coiled tube heat exchanger and multi-flow technology, which is applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problem that the single coiled tube heat exchanger cannot meet the demand, etc. It achieves the effect of facilitating subsection processing, reducing power consumption and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

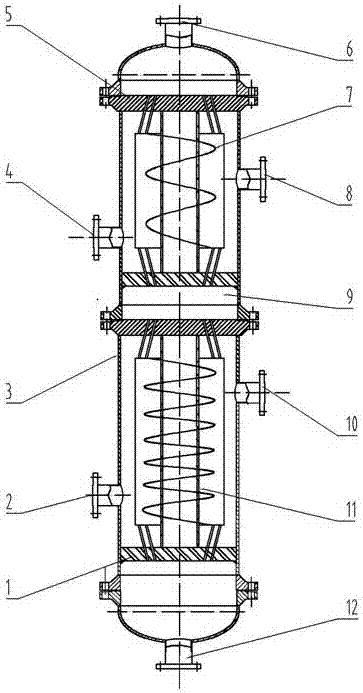

[0015] Embodiment 1, for the shell-side multi-stream flow wound tube heat exchanger with flange connection between the cylinders of different shells and between the cylinder and the pipe box, firstly, the core cylinder of each shell side of the heat exchanger The two ends are respectively welded and fixed at the center of the two tube sheets, one end of the winding tube is inserted into the tube sheet, and then wound on the core barrel according to the designed helix angle, the other end of the winding tube is inserted into the flanged tube sheet, and the winding tube The connection between the two ends of the tube plate and the tube plate adopts the method of first expansion and then welding; the axial distance between the winding tubes of the same layer is fixed by positioning strips, and the positioning strips are welded and fixed on the bottom strips in advance, and the bottom strips are arranged along the axial direction of the core tube. It is welded and fixed on the core...

Embodiment 2

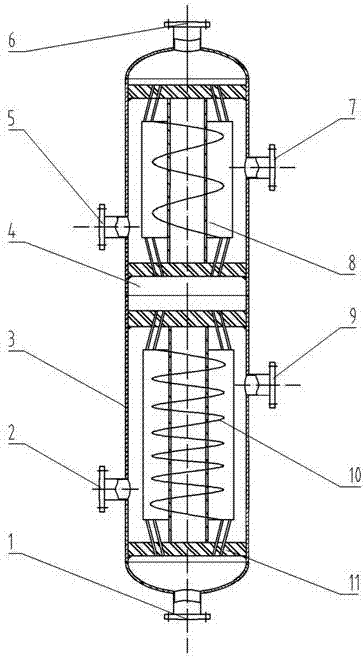

[0016] Embodiment 2, for the shell-side multi-stream flow-wound tube heat exchanger with butt welding connection between the shells of different shells and between the shell and the pipe box, firstly, the two ends of the core tube of each shell are respectively It is welded and fixed at the center of the two tube sheets, and one end of the winding tube is first inserted into the tube sheet, and wound on the core barrel according to the designed helix angle, and then the other end of the winding tube is inserted into another tube sheet, and the winding tube The connection between both ends and the tube sheet adopts the method of first expansion and then welding; the axial distance between the winding tubes of the same layer is fixed by positioning strips, which are welded and fixed on the bottom strips in advance, and the bottom strips are arranged along the axial direction of the core tube, and Welding and fixing on the core barrel or the bottom winding pipe; the winding direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com