Three-dimensional optical fiber acceleration sensor with strong electromagnetic interference-resistant capability

An acceleration sensor and strong electromagnetic interference technology, applied in multi-dimensional acceleration measurement, acceleration measurement using inertial force, etc., can solve the problems of narrow operating frequency bandwidth of the sensor, potential safety hazards of electrode discharge, and low sensitivity, so as to improve the convenience of production, Effect of suppressing residual jitter and polarization fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] A kind of anti-strong electromagnetic interference three-dimensional optical fiber acceleration sensor of the present invention is described in further detail below in conjunction with accompanying drawing and specific embodiment, but the present invention is not limited to this embodiment:

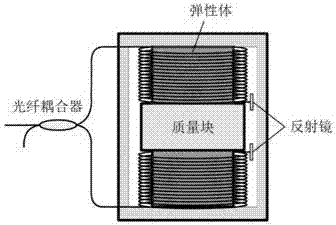

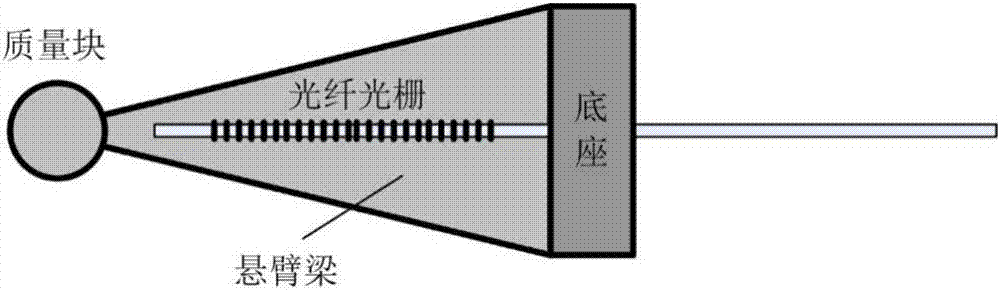

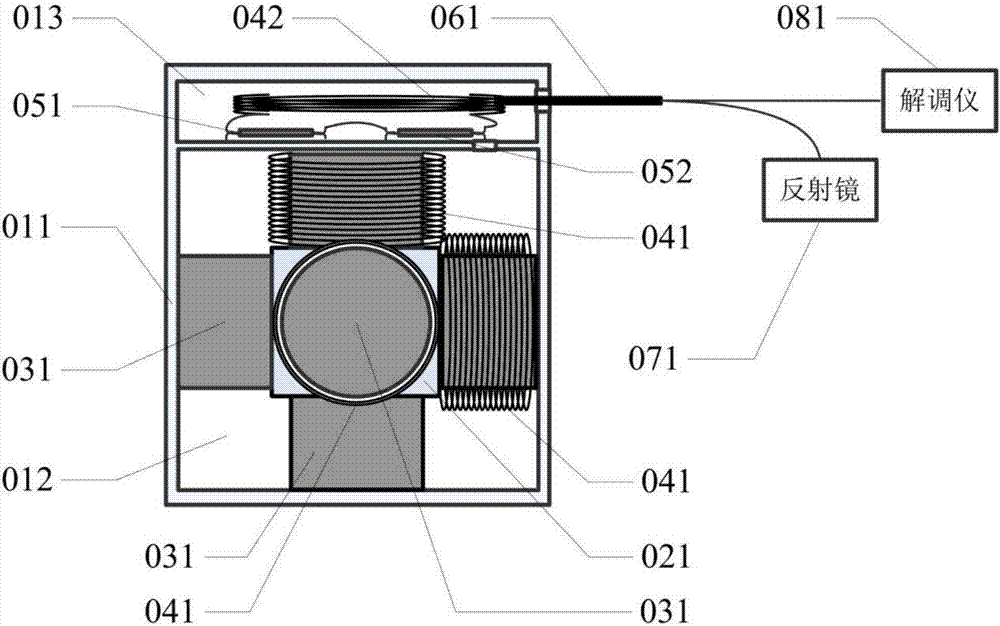

[0040] The working mechanism of the three-dimensional optical fiber acceleration sensor with strong electromagnetic interference resistance of the present invention is: when the sensor is subjected to the acceleration vibration signal, the inertial force of the mass block 021 will cause the elastic sensitive element 031 to undergo stretching and compression deformation, thereby causing the sensor to be wound around The sensing fiber 041 on the elastic sensitive element 031 produces a strain change related to the acceleration vibration, and the strain change of the sensing fiber 041 is converted into an optical phase change by an improved optical fiber Mach-Zehnder interferometer. Ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com