Analog compensation-based temperature compensation high-frequency crystal oscillator

A crystal oscillator, temperature compensation technology, applied in the direction of output stability, electrical components, etc., can solve the problem of failure to make a breakthrough in the frequency temperature characteristics of temperature compensated crystal oscillators, restricting the frequency compensation accuracy of temperature compensated high frequency crystal oscillators, and temperature sensors Problems such as temperature hysteresis of the resonant chip, easy real-time high-precision compensation, easy integration and mass production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

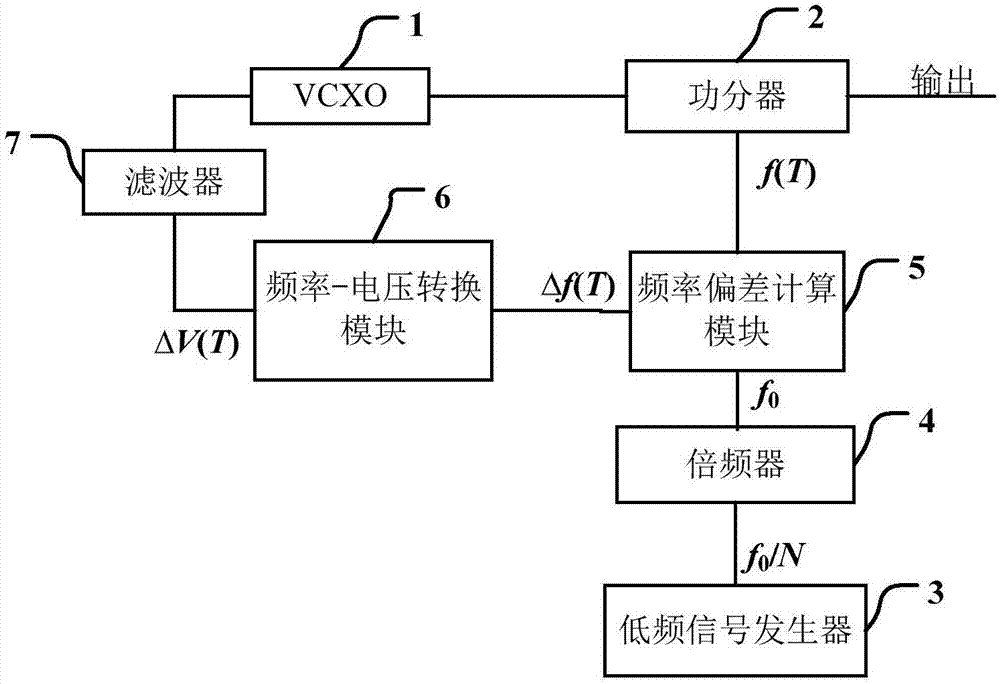

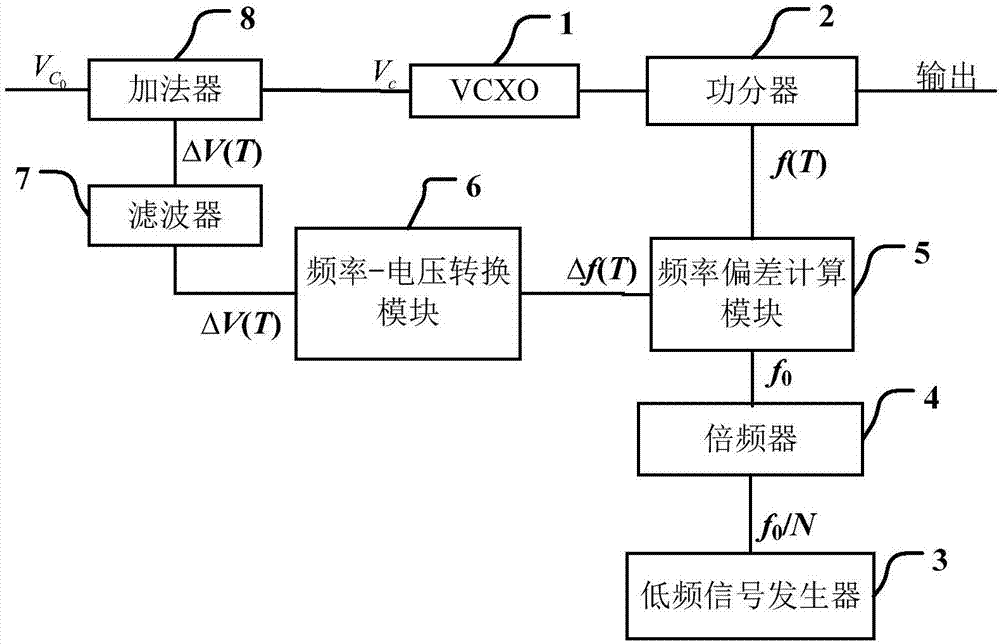

[0050] In this embodiment, with the output signal frequency f 0 Take 100MHz as an example. Now the frequency stability of the 100MHz temperature-compensated crystal oscillator on the market is about 1ppm, and now the 10MHz temperature-compensated crystal oscillator (the temperature-frequency stability of the 10MHz temperature-compensated crystal oscillator on the market can reach about 0.28ppm) is frequency multiplied to obtain a frequency ratio of 100MHz. For the signal, the temperature frequency stability of the output signal with a frequency of 100MHz can be increased to about 0.28ppm without affecting its phase noise.

[0051] combine figure 2 , the power divider 2 divides the f(T)=100MHz signal output by the voltage-controlled crystal oscillator, that is, the VCXO 1, into two channels, one for normal output, and one for output to the frequency deviation calculation module 5 .

[0052] The frequency deviation calculation module 5 compares the f(T) input by the power div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com