Bamboo carbonization harvester

A harvester and bamboo technology, applied in agriculture, forestry, application, etc., can solve the problems of large volume, waste, and high labor intensity of chain saws, and achieve the effects of low control technology requirements, reduced production costs, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

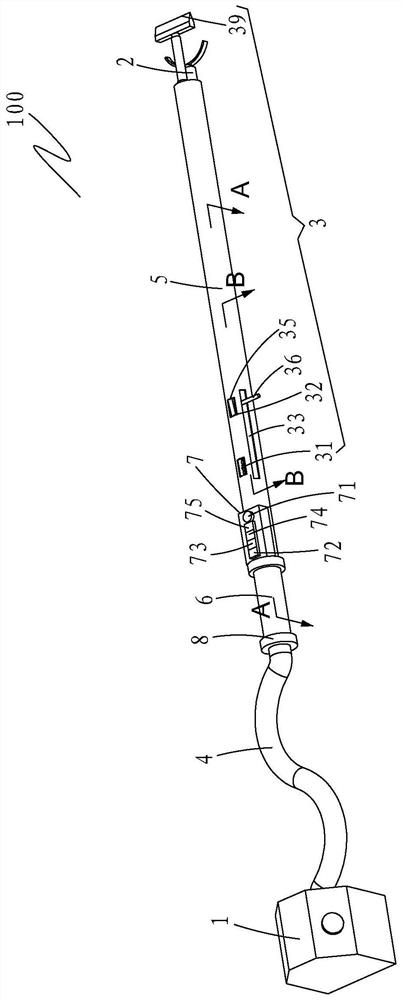

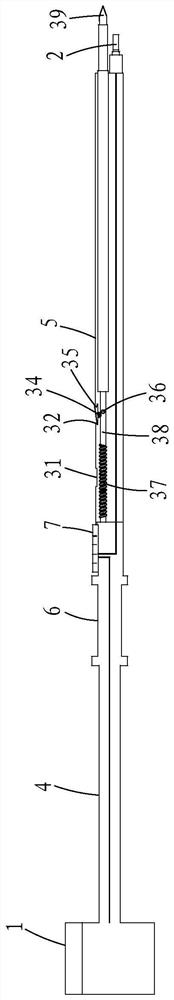

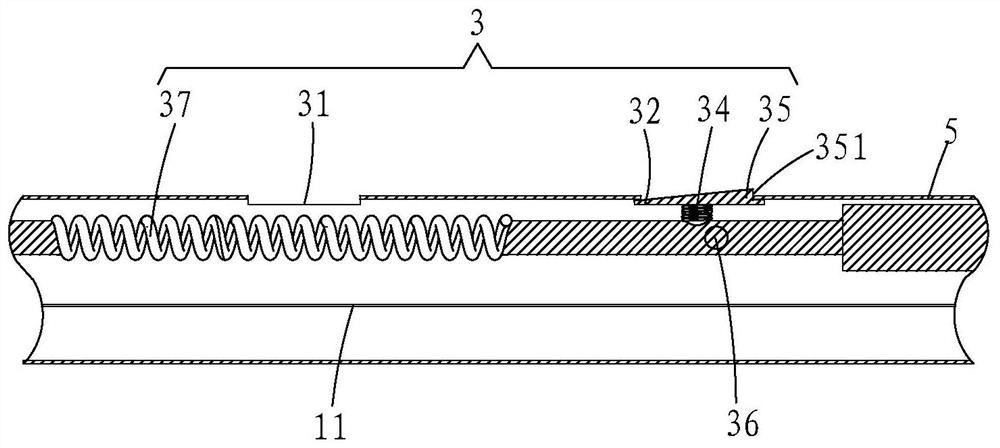

[0019] see figure 1 and figure 2 As shown, a bamboo carbonization harvester 100 includes a gasoline generator 1, an electric soldering iron 2, a telescopic cutter 3, a flexible conduit 4, a rigid sleeve 5, a handle 6 and a temperature controller 7; the electric soldering iron 2 Electrically connected to the gasoline generator 1 , the telescopic cutter 3 is disposed adjacent to the electric soldering iron 2 . One end of the flexible conduit 4 is connected to the gasoline generator 1, and the other end is connected to the hard sleeve 5 through the connector 8. The electric iron 2 is arranged on the free end of the hard sleeve 5; the telescopic cutter 3 It can be moved back and forth on the hard sleeve 5 and is parallel to the electric soldering iron 2 . The hard sleeve 5 is an aluminum alloy hard sleeve 5, and the electric soldering iron 2 is arc-shaped. The handle part 6 and the temperature controller 7 are both arranged on the hard sleeve 5; the temperature controller 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com