A landfill mineralized waste sorting device and its application resource treatment system

A technology of mineralized garbage and sorting device, which is applied in the direction of cyclone, magnetic separation, solid separation, etc., can solve the problems of mineralized garbage sorting, that is, low resource utilization efficiency, and achieve the effect of improving the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

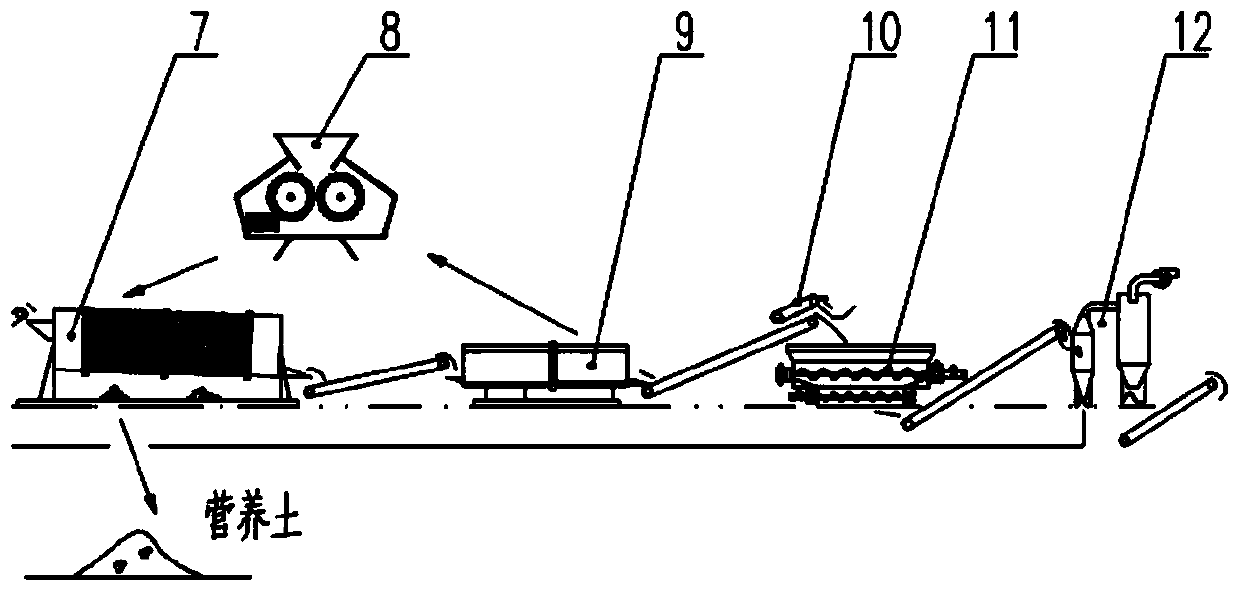

[0049] see figure 1 , the landfill mineralized waste sorting device in the illustration is a preferred solution of the present invention, specifically including trommel 7, crushing equipment 8, combustibles sorting equipment 9, magnetic separation equipment 10, rotary crushing equipment 11 and Cyclone air separation equipment 12, wherein drum screen 7, combustibles sorting equipment 9, magnetic separation equipment 10, rotary crushing equipment 11 and cyclone air separation equipment 12 are connected in series by conveyor belts in sequence, and crushing equipment 8 is connected with drum screen 7 and combustibles sorting equipment. The selection equipment 9 is connected into a circulation conveying system, and the mineralized garbage after screening is subjected to at least two circulation separations.

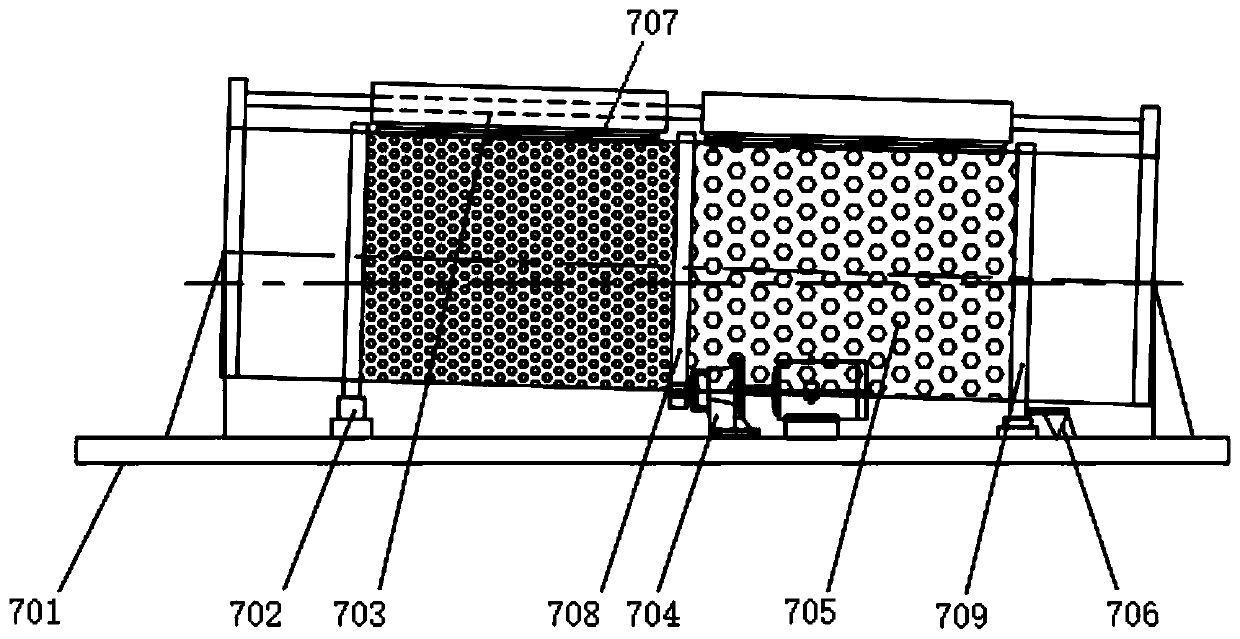

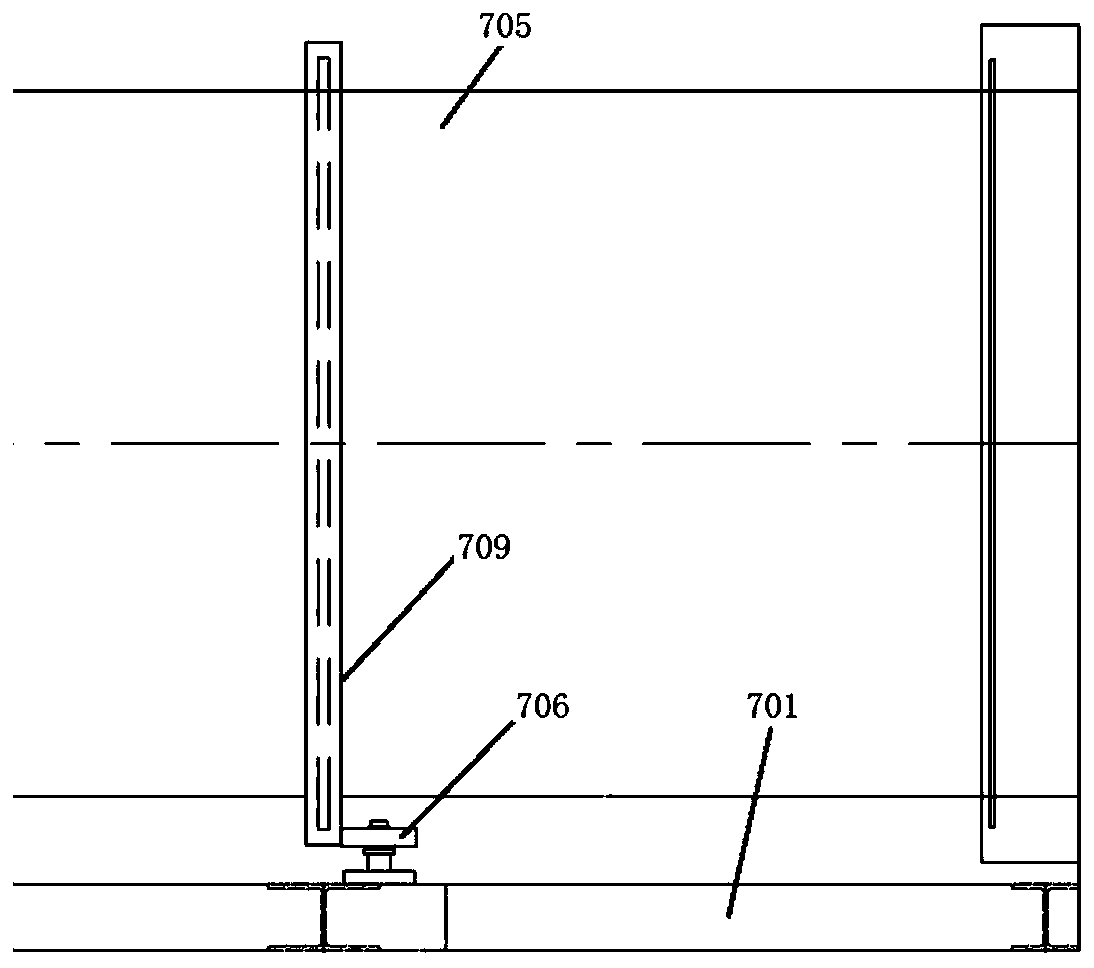

[0050] Such as Figure 2a , 2b As shown in and 2c, the trommel 7 includes an inclined drum 705, the two ends of which are open. 705 is in drive connection with the power as...

Embodiment 2

[0062] see Figure 5 , a landfill mineralized waste resource treatment system in this embodiment is a preferred solution for applying the sorting device in the first embodiment. When the sorting device in the first embodiment is used, it also includes the front section of the trommel 7. Mineralized waste excavation equipment, conveying and storage equipment, and drying equipment 13, crushing equipment 15 and high-pressure extrusion equipment 16 arranged in the rear section of the cyclone air separation equipment 12 in sequence.

[0063] Specifically, the exploration drilling rig 1 samples and analyzes the mineralized waste under the landfill, and the excavator 2 digs out the deeply buried mineralized waste in the landfill. The transport vehicle 4 is transported to the silo 5 for storage, and the conveyor belt 6 transports the mineralized waste from the silo 5 to the drum screen 7, and the drum screen 7 is respectively connected with the crushing equipment 8 and the combustible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com