Manufacturing method of 500MPa-grade zinc-iron alloy coating dual-phase steel plate for automobile outer panel

A technology of zinc-iron alloy and manufacturing method, which is applied in the field of manufacturing zinc-iron alloy-coated dual-phase steel sheets for 500MPa-level automotive outer panels, can solve the problems of low surface quality requirements and insufficient attention to surface quality, and achieve color without defects , Excellent anti-powdering performance, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

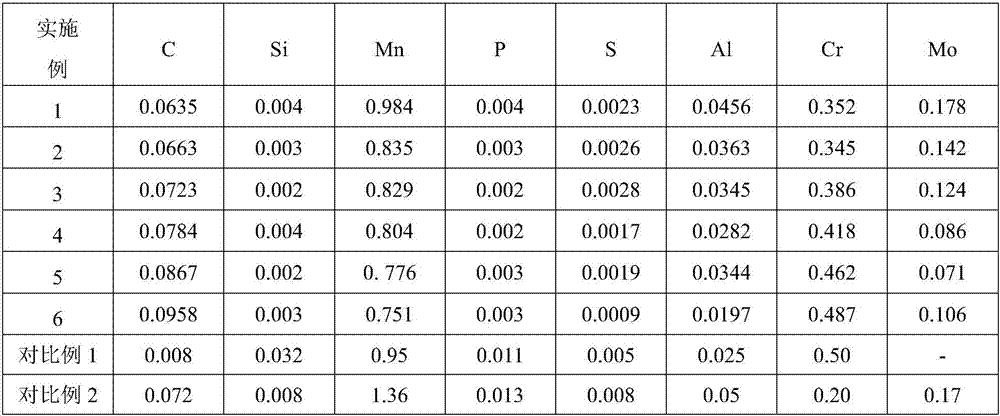

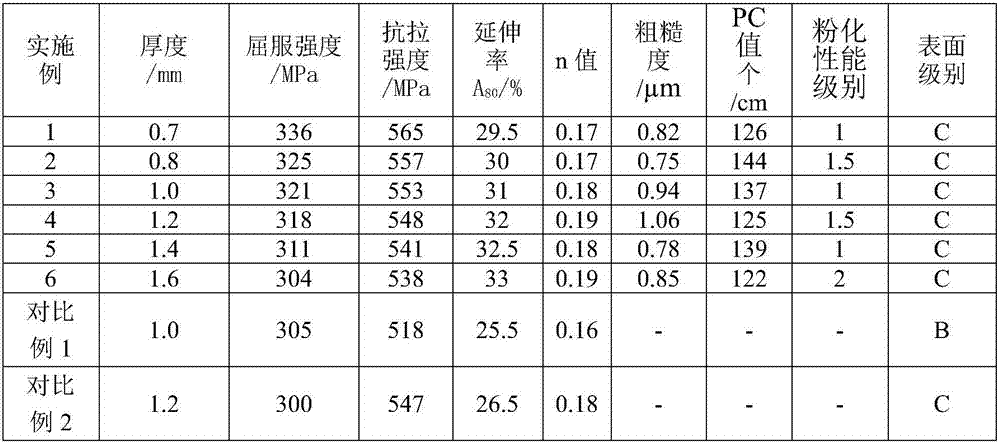

[0017] Embodiment: a kind of manufacturing method of zinc-iron alloy coated dual-phase steel sheet for 500MPa level automobile outer panel, comprises the following steps:

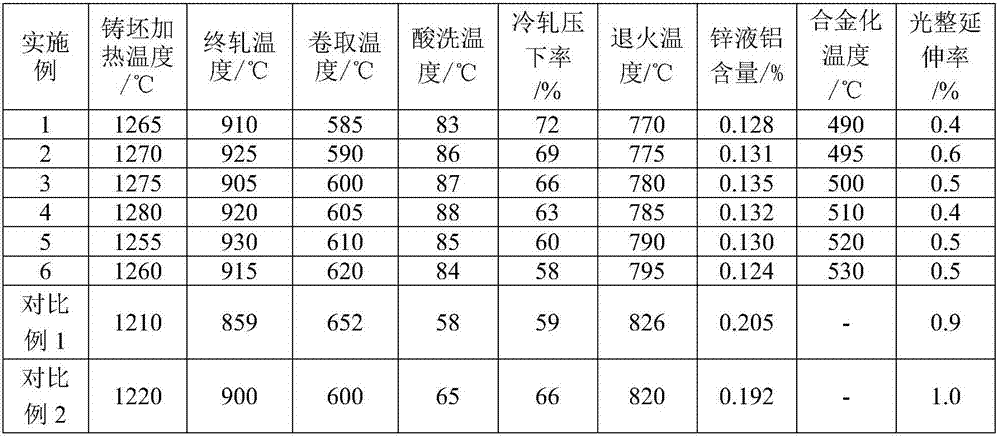

[0018] 1) After the steel is smelted, refined and continuously cast into a slab, the slab is heated, and the heating temperature is controlled at 1250-1280°C;

[0019] 2) Carry out rough rolling, and control the rough rolling temperature at 1060-1110°C;

[0020] 3) Carry out finish rolling, and control the finishing rolling temperature at 900-930°C;

[0021] 4) Carry out coiling, and control the coiling temperature at 580-620°C;

[0022] 5) Carry out pickling, the pickling temperature is controlled at 80-90°C, and the acid concentration is greater than 70g / l;

[0023] 6) Carry out cold rolling, and control the total reduction rate of cold rolling at 58% to 72%;

[0024] 7) Carry out continuous annealing: control the soaking temperature at 770-800°C, control the dew point of the annealing atmosphere in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com