Overwater bearing construction platform and installation method thereof

A technology of construction platform and installation method, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of complicated design and construction, long construction period, affecting efficiency, etc., to achieve convenient installation and construction, short construction period, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

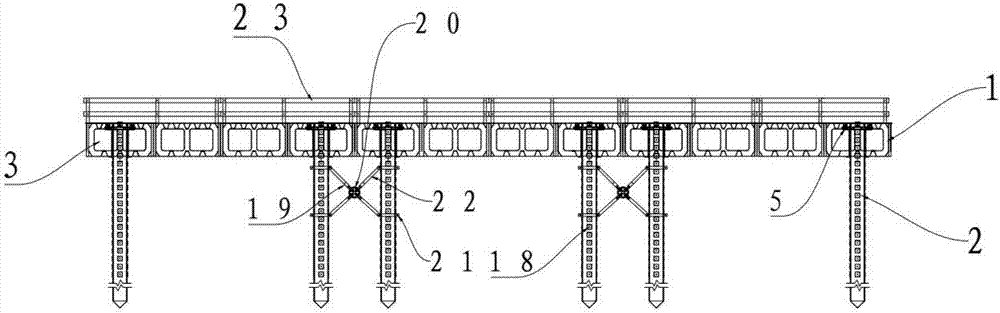

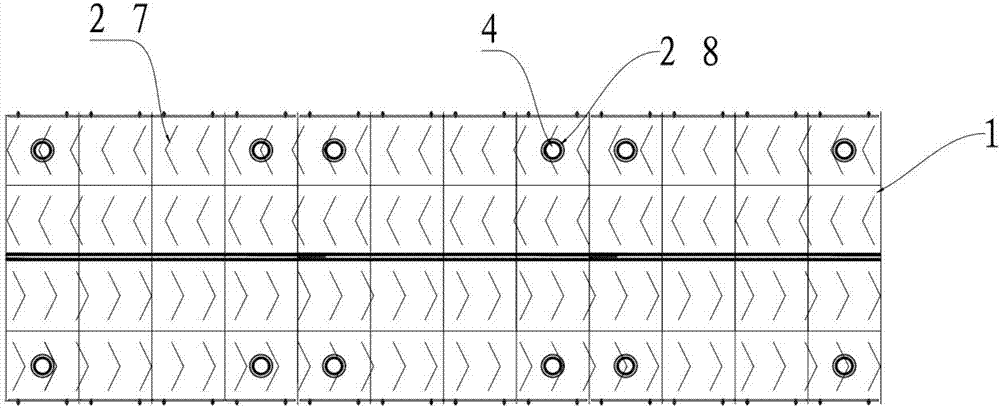

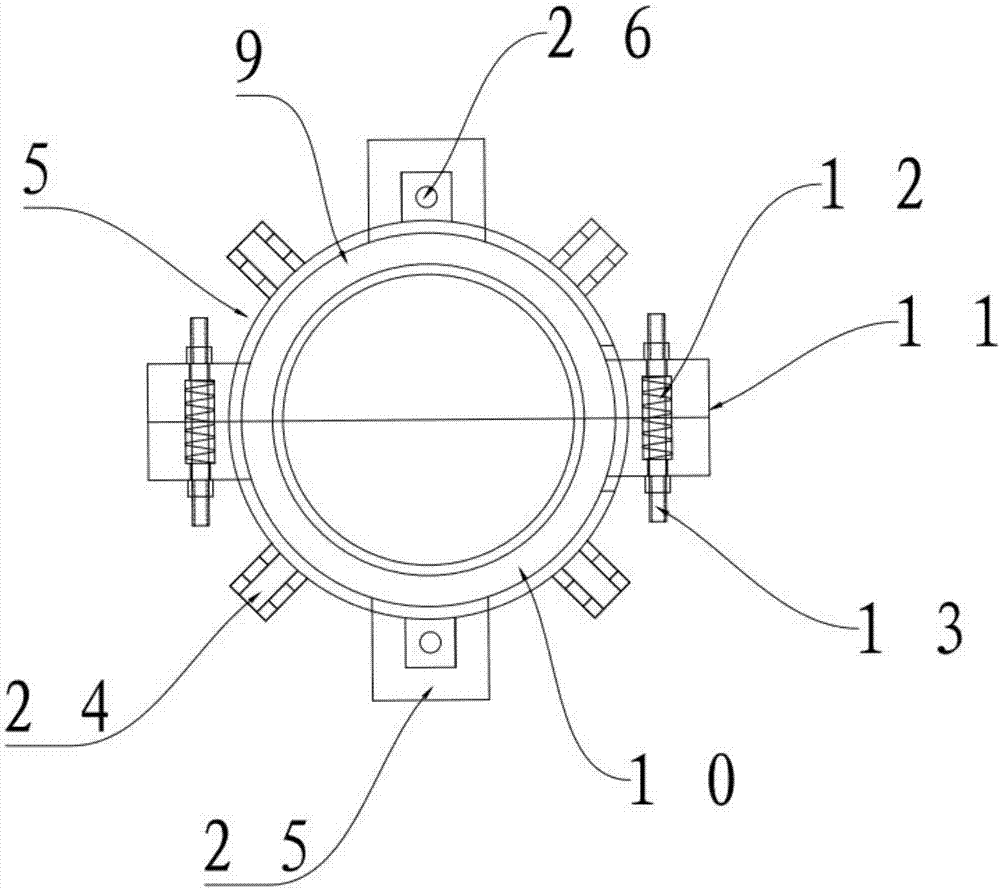

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the load-bearing construction platform on water includes a construction platform body 1 and several steel pipe piles 2 located at its bottom. The construction platform body 1 includes several fixedly connected box beams 3. There is an installation hole 4, and a connector 5 is arranged on the installation hole 4, and the connector 5 includes a steel pipe pile casing 6 arranged in the installation hole 4, and a clamp arranged at the upper end of the steel pipe pile casing 6 Fixer 7 and the steel pipe support 8 that is located on the clamper 7, said clamper 7 includes a left embracing device 9 and a right embracing device 10 forming a ring, and said left embracing device 9 and right embracing device 10 The left and right sides of the connecting block 11 are respectively provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com