On-line detection device for steel cord fabric

A detection device and steel cord technology, applied in the field of tire production, can solve the problems of inconvenient installation and maintenance of equipment, expensive equipment, heavy equipment, etc., and achieve the effects of convenient maintenance, safe use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

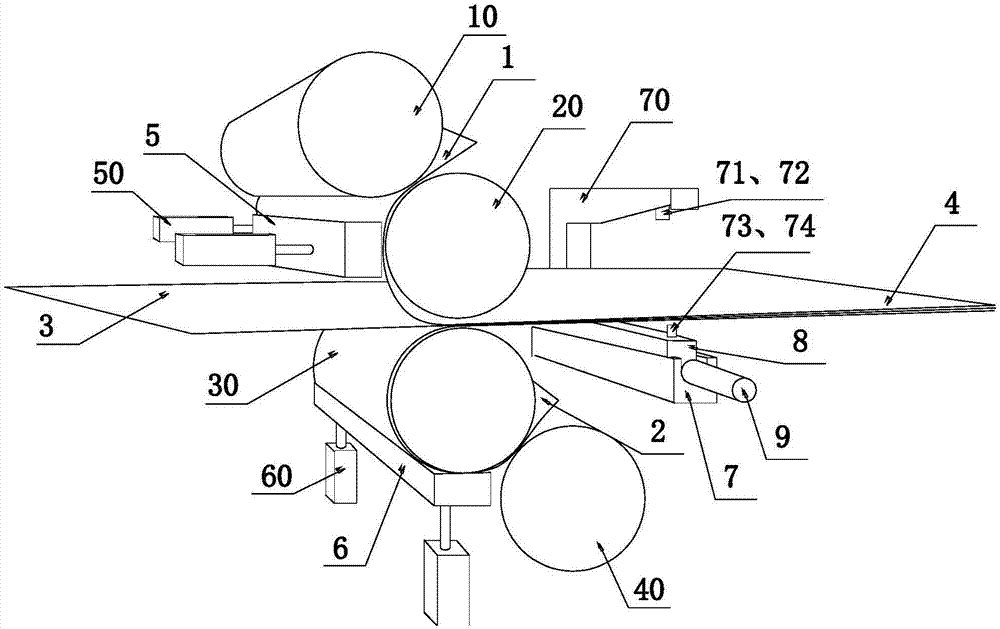

[0018] like figure 1 An on-line detection device for a steel cord is shown, which includes an upper film thickness detection device 5 , a lower film thickness detection device 6 , a total cord thickness detection device and a steel wire levelness detection device 7 .

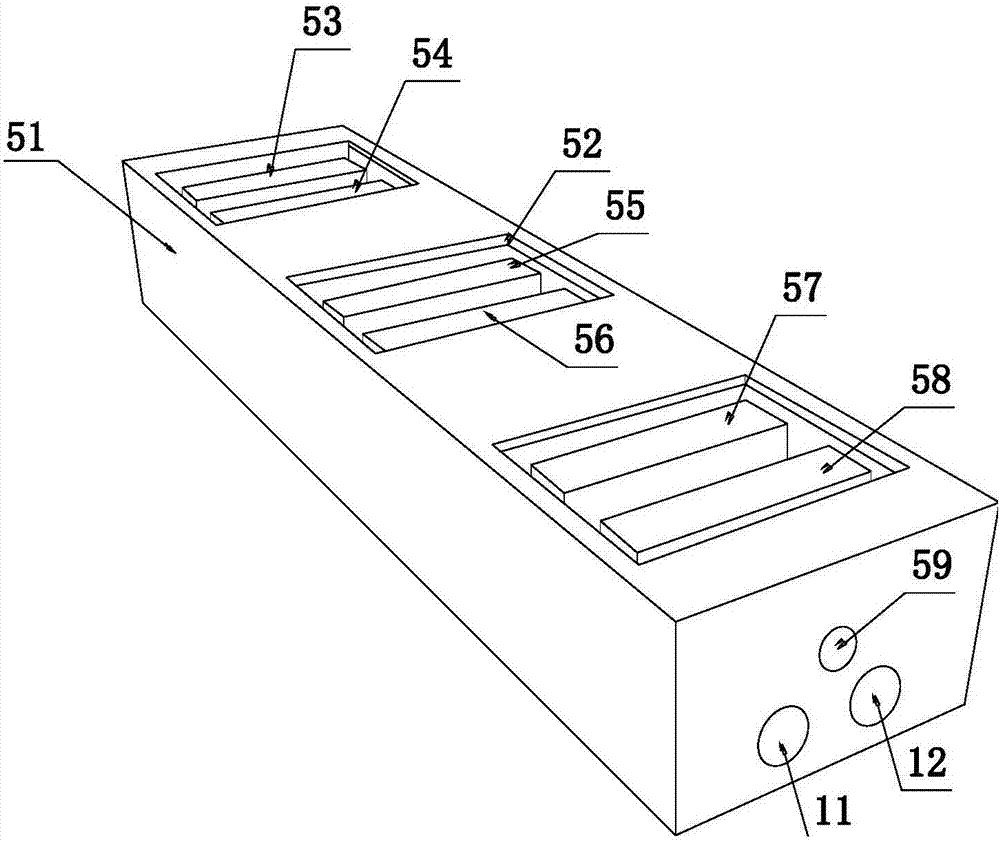

[0019] like figure 2 As shown, the film thickness detection device 5 is composed of a first bracket 51, a first telescopic cylinder 50, a first laser sensor 53, a first eddy current sensor 54, a second laser sensor 55, a second eddy current sensor 56, The third laser sensor 57 and the third eddy current sensor 58, the first bracket 51 is arranged behind the second calendering roll 20 through the first telescopic cylinder 50, and the first bracket 51 is longitudinally facing the second calendering roll Three first sensor installation ports 52 are provided, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com