High-voltage electric appliance fiber gating temperature measuring system

A technology of optical fiber gratings and high-voltage electrical appliances, which is applied in the field of temperature monitoring equipment, can solve problems such as the inability to realize the temperature measurement of the switch cabinet knife switch connection points and contacts, the limit of the safe operation level of the power system, and the unusable sensors, etc., to reduce the number and The effect of workload, reliable power guarantee, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

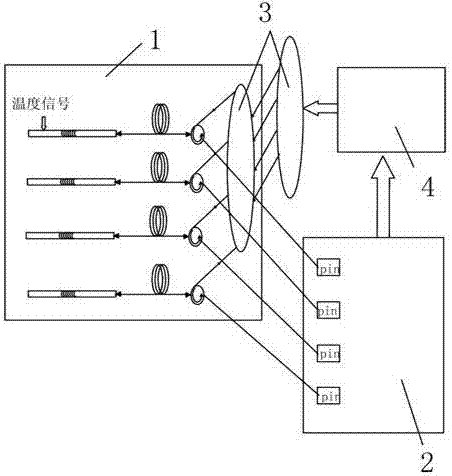

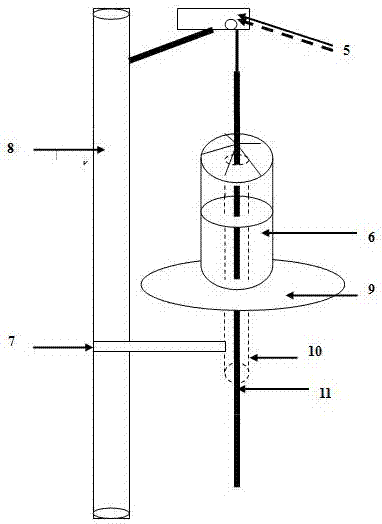

[0023] figure 1 The fiber grating temperature sensor of the present invention is shown to illustrate the working principle of the system; the present invention is developed based on the principle of optical fiber grating photosensitivity, and the temperature detection optical cable 1 is distributed at the measurement point, and the temperature signal at this point is collected; the external temperature The changed temperature signal is transmitted to the fiber grating temperature detector, which causes the drift of the center wavelength of the laser through the fiber grating. According to the experimental research, the drift of the laser center wavelength is linear with the temperature change; the signal demodulation analysis of the back-en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com