Blue photosensitive resin composition, blue color filter and display device comprising the same

A technology of photosensitive resin and display elements, which is applied in the direction of photosensitive materials, optics, instruments, etc. used in optomechanical equipment, can solve the problems of light and dark contrast and visibility reduction, and achieve the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0173] Synthesis example 1. Synthesis of alkali-soluble resin

[0174] In a 1000mL flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen introduction tube, 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, 2 parts by weight of AIBN, Nitrogen substitution was carried out with 13 parts by weight of acrylic acid, 10 parts by weight of benzyl methacrylate, 57 parts by weight of styrene, 20 parts by weight of methyl methacrylate, and 3 parts by weight of n-dodecylmercaptan. Then, stirring was performed to raise the temperature of the reaction liquid to 110° C., and after the temperature was raised, it was allowed to react for 6 hours.

[0175] The solid content acid value of the alkali-soluble resin produced in this way was 100.2 mgKOH / g, and the weight average molecular weight Mw measured by GPC was about 15110.

[0176]

Embodiment 1~6 and comparative example 1~2

[0178] The cyan photosensitive resin compositions of Examples 1-6 and Comparative Examples 1-2 were manufactured with the composition of following Table 1.

[0179] [Table 1] (Unit: parts by weight)

[0180]

[0181] (A-1) Cyan pigment: C.I. Pigment Blue 15:6

[0182] (A-2) Cyan pigment: C.I. Pigment Blue 15:4

[0183] (A-3) Violet pigment: C.I. Pigment Violet 23

[0184] (A-4) Black pigment: PBk7: Carbon-black (MA-8, Mitsubishi Corporation)

[0185] (B) Alkali-soluble resin: Alkali-soluble resin produced in Synthesis Example 1

[0186] (C) Photopolymerizable compound: dipentaerythritol hexaacrylate (KAYARD DPHA; manufactured by Nippon Kayaku Co., Ltd.)

[0187] (D) Photopolymerization initiator: 2-O-benzoyl oxime-1-[4-(phenylthio)phenyl]-1,2-octanedione (OXE-01; manufactured by BASF)

[0188] (E) Solvent: Propylene Glycol Monomethyl Ether Acetate

experiment example 1

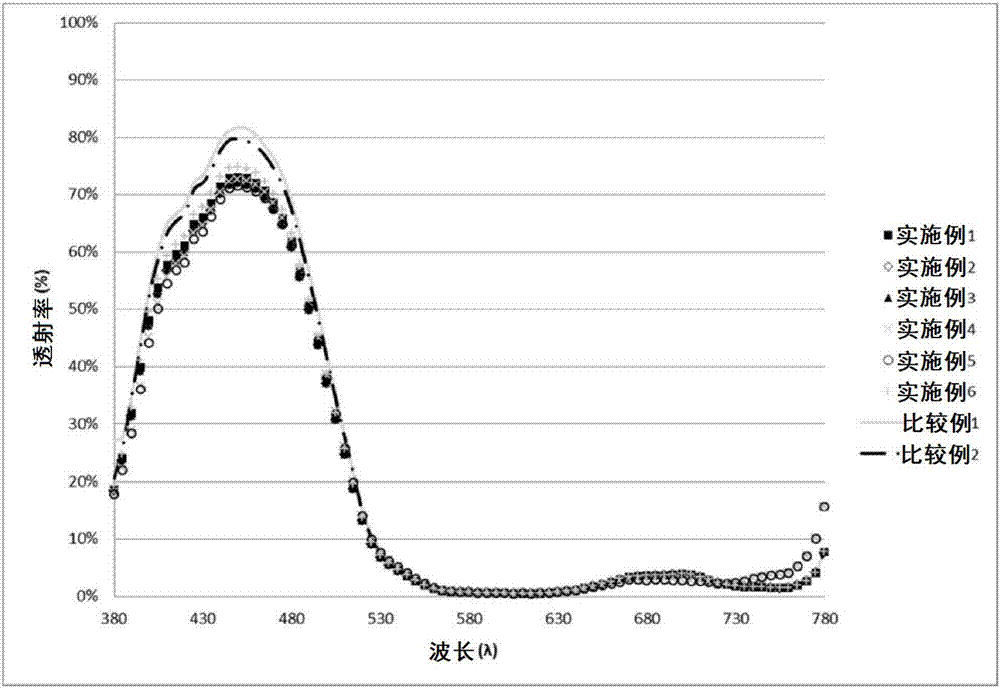

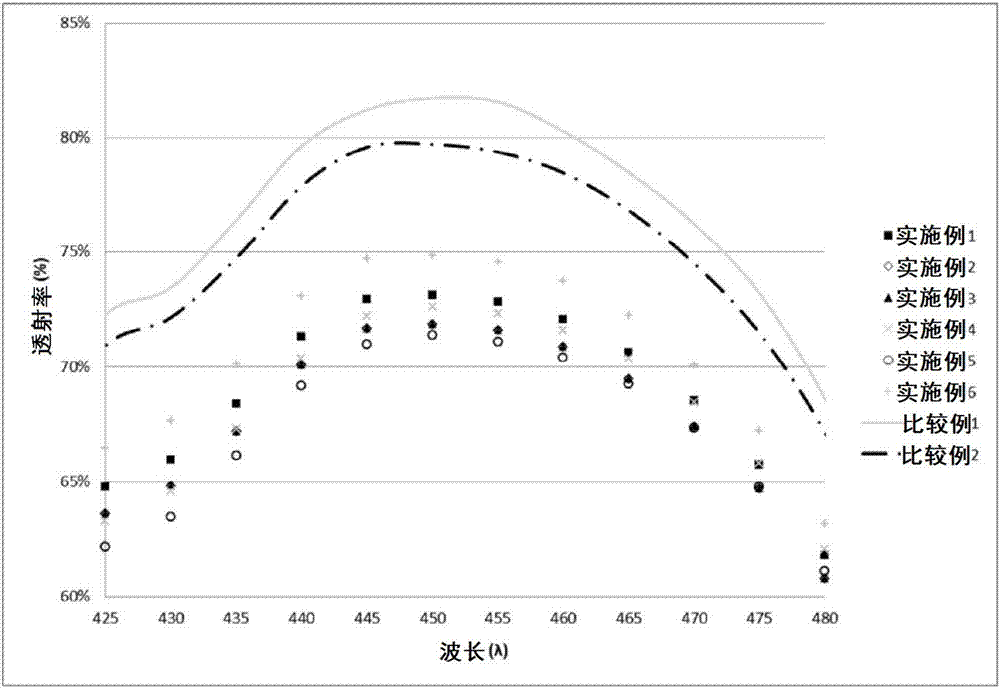

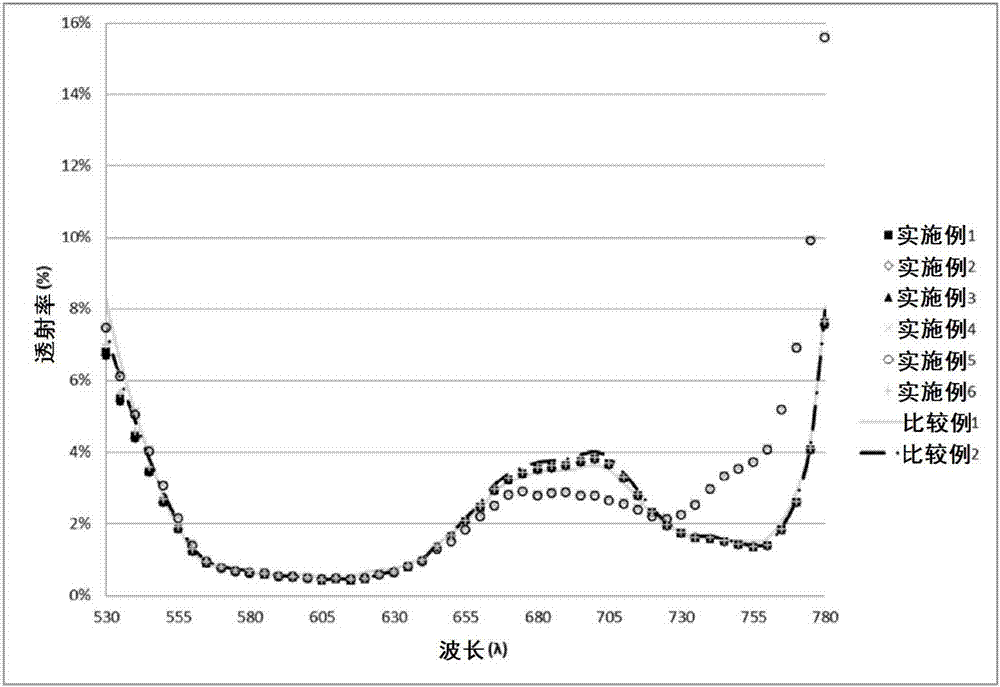

[0189] Experimental example 1. Production of color filter and measurement of spectral transmittance

[0190] The cyan photosensitive resin compositions of Examples 1 to 6 and Comparative Examples 1 to 2 were each applied by spin coating on a 2-inch glass substrate (manufactured by Corning Incorporated, "EAGLE XG"), and placed on a hot plate. , maintained at a temperature of 100° C. for 3 minutes to form a thin film.

[0191] Then, a test photomask having a pattern with a stepwise change in transmittance in the range of 1 to 100% and an exposed portion pattern of 3×3 cm was placed on the above-mentioned film, and the distance between the test photomask and the test photomask was 100 μm, and ultraviolet rays were irradiated. . At this time, the ultraviolet light uses a 1kW high-pressure mercury lamp containing all g, h and i lines, at a rate of 100mJ / cm 2 illuminance without the use of special optical filters.

[0192] The film irradiated with the above-mentioned ultraviole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com