An electronic kanban system in a machining workshop

An electronic kanban and mechanical processing technology, applied in general control systems, control/regulation systems, data processing applications, etc., can solve the problems of too little processing information collection and insufficient consideration of workshop space factors, and achieve fast information transmission speed, Good remote monitoring ability and the effect of flexible mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

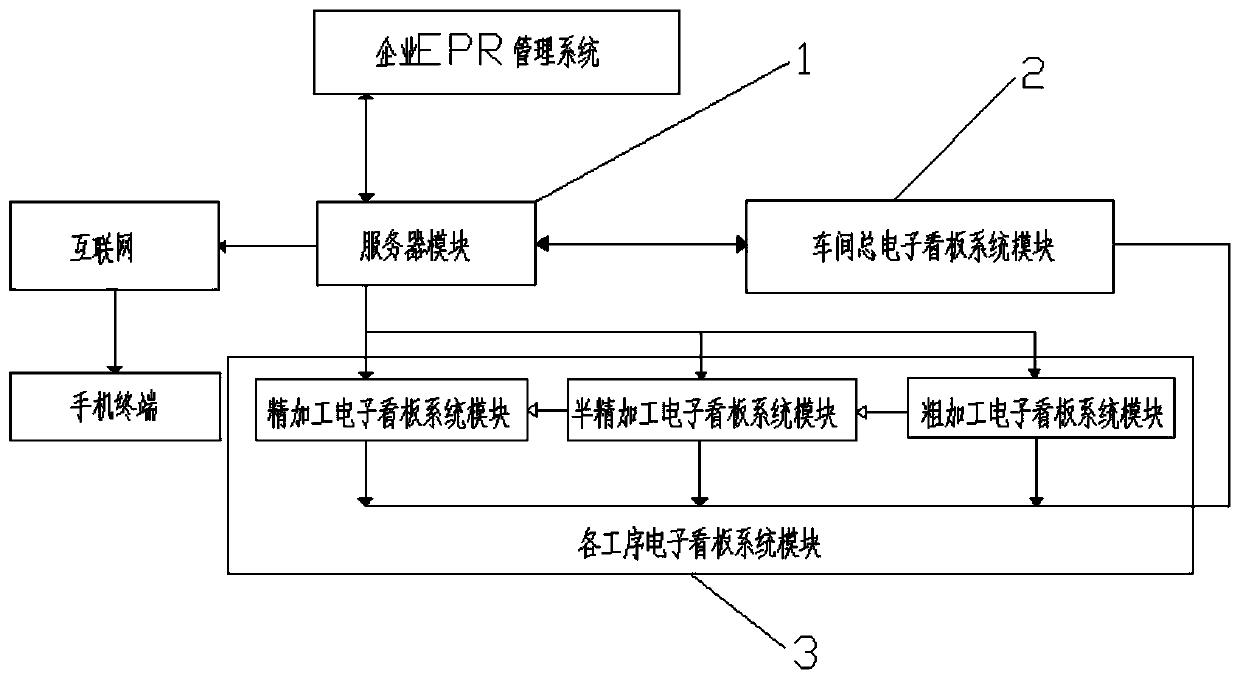

[0033] Embodiment 1: This embodiment provides an electronic kanban system in a machining workshop, such as figure 1 As shown, the server module 1 of the electronic kanban system is connected to the ERP system of the enterprise, obtains machining tasks, connects to the CAN transceiver PCA82C250, and sends machining task information to the electronic kanban system module 3 of each process; receives the information sent by the total electronic system module 2 of each workshop processing information and save it.

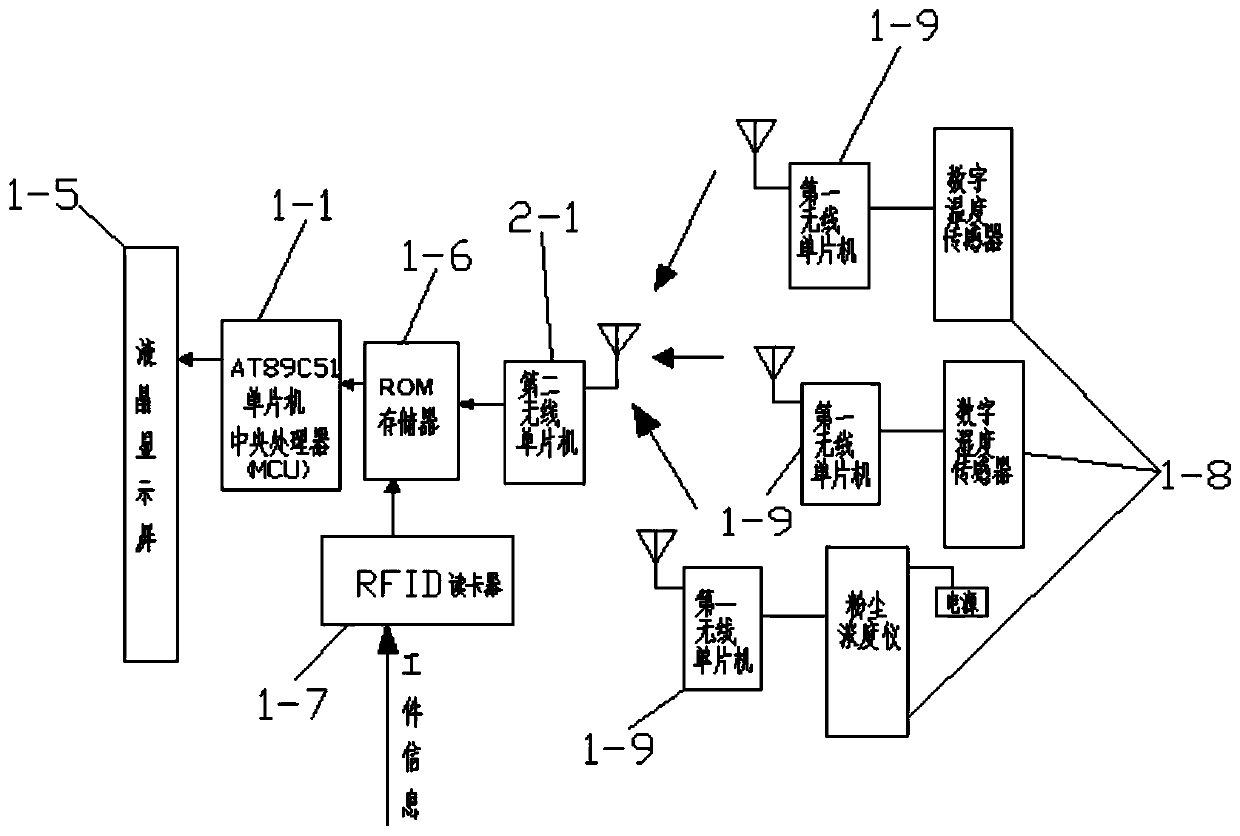

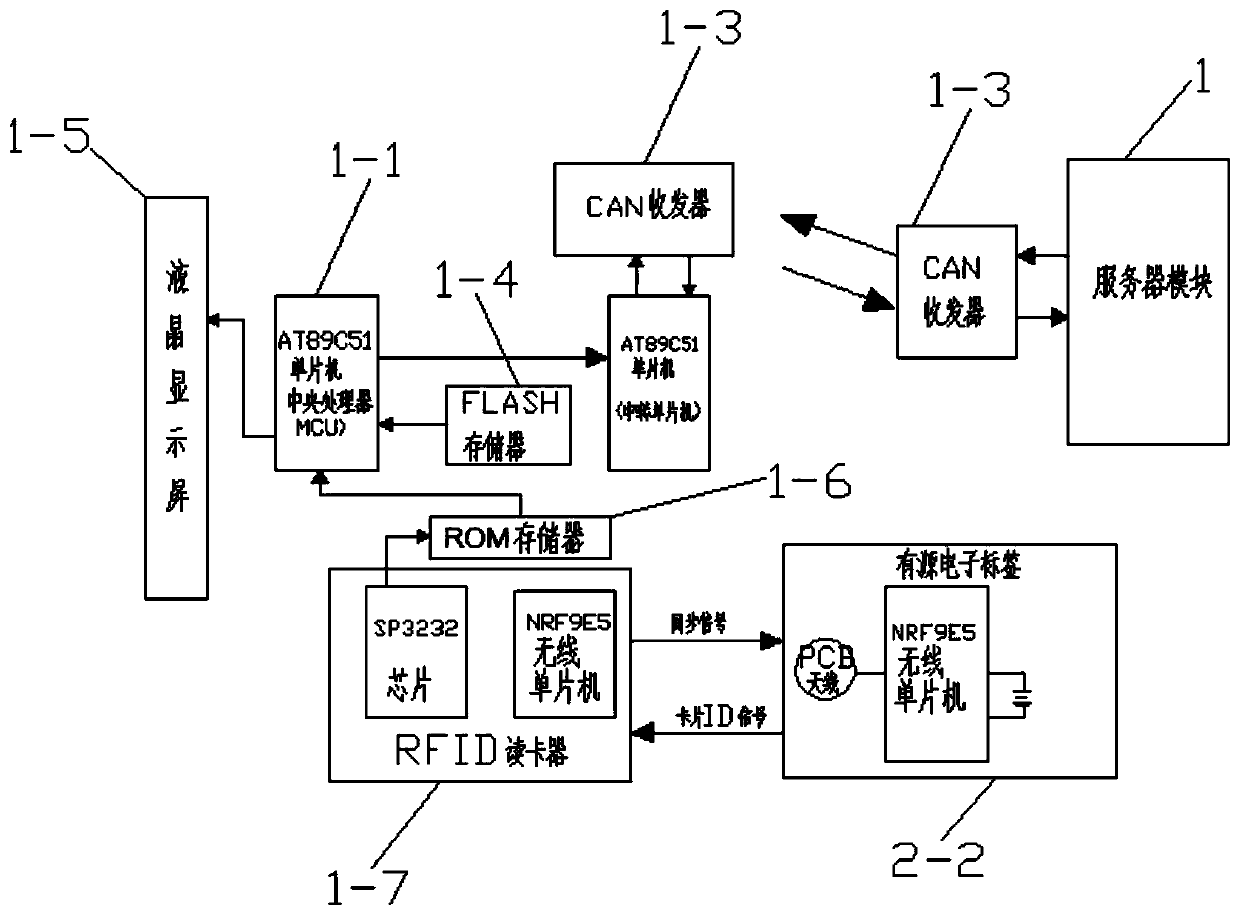

[0034] like Figure 4 As shown, the total electronic kanban system module 2 of the workshop adopts AT89C51 single-chip microcomputer as the central processing unit (MCU) 1-1, and the central processing unit (MCU) 1-1 connects information transfer single-chip microcomputer (AT89C51) 1-2, and transfers single-chip microcomputer (AT89C51) 1-2 Connect CAN transceiver (PCA82C250) 1-3, central processing unit (MCU) 1-1 connect FLASH memory chip (SST25VF016B) 1-4 and LCD scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com