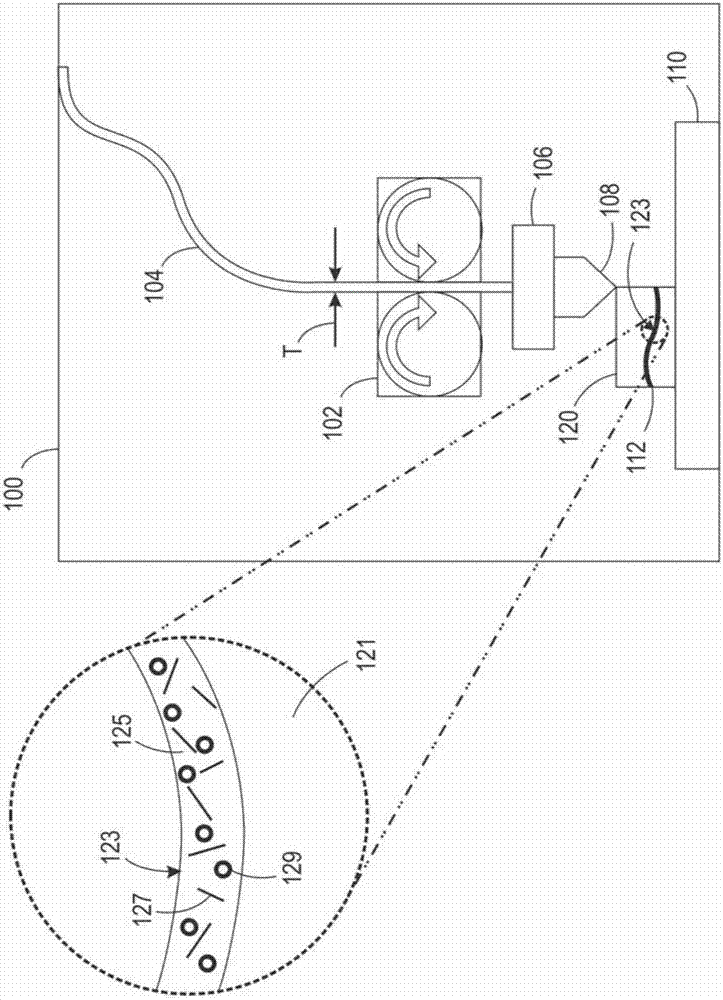

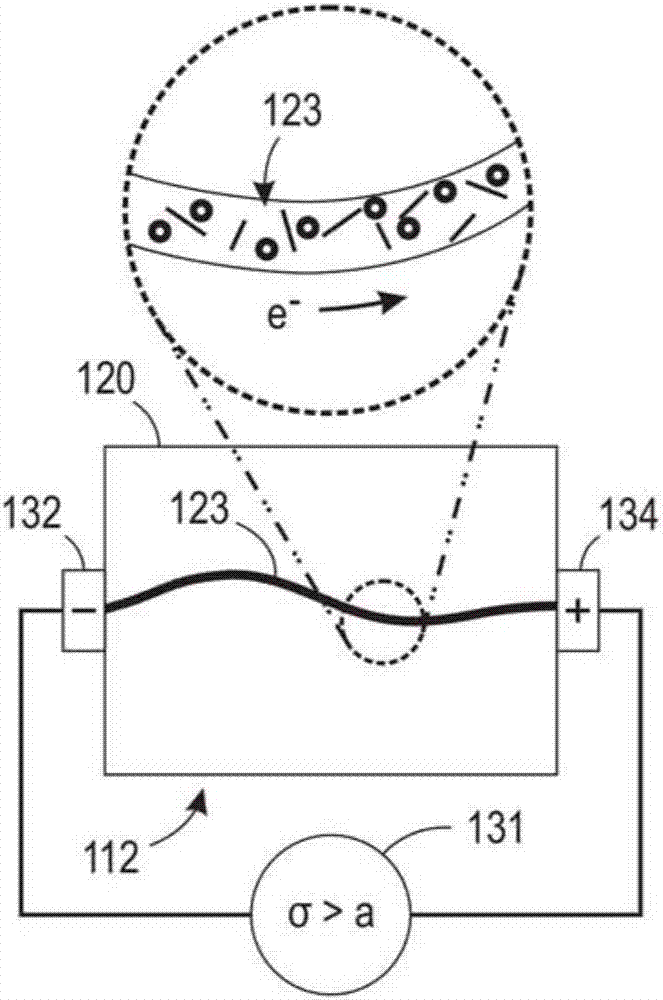

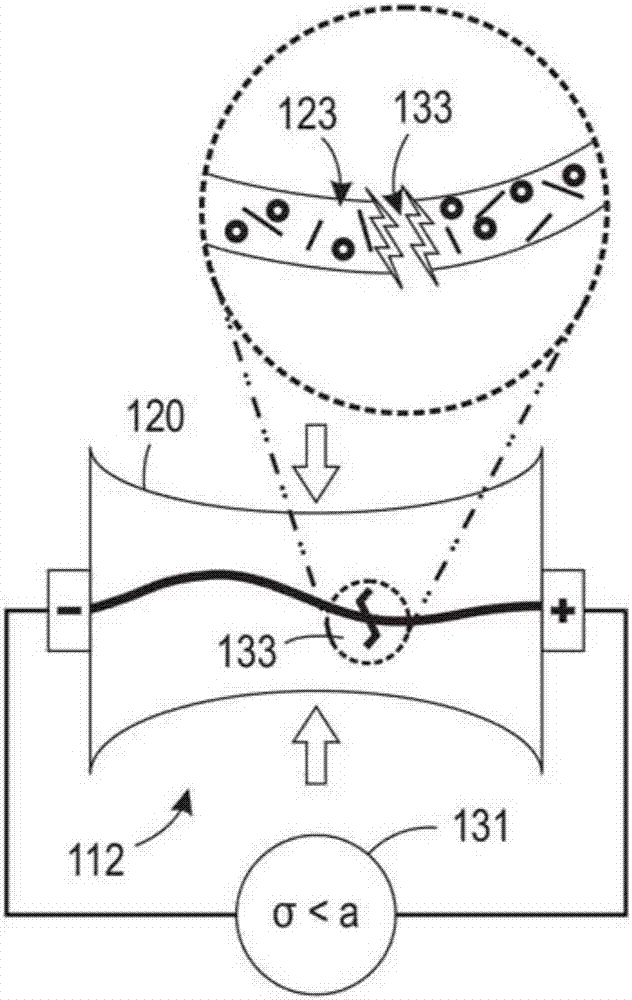

3D printed conductive compositions anticipating or indicating structural compromise

A 3D printing and composite technology, applied to the conductive layer on the insulating carrier, the conductive coating, the equipment used to manufacture the conductive/semiconductive layer, etc., can solve the problem of low conductivity and achieve the effect of increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0066] By extruding a polymer substrate (polycaprolactone; "PCL") with 10% by weight of multi-walled carbon nanotubes (MWNT) together with 30% by weight of silver (Ag) flakes on a Haake twin-screw extruder Conductive composite segments were prepared by melt mixing at 30 rpm for 30 minutes. The resulting material was cryogenically ground and the ground compound was extruded into filaments using a melt flow indexer (MFI) and a modified die. Extrusion conditions on the MFI included a 1.8 mm hole and a 16.96 kg weight in order to produce the final filament. The final filament has a diameter of about 1.75mm.

example 2

[0068] A 10 cm cross-section of the extruded filament of Example 1 with the tip coated with silver paint was used to measure electrical resistance in order to calculate bulk conductivity. Resistance measurements are done using a digital multimeter. The bulk conductivity was calculated using Equation 1 above.

example 3

[0070] A composite similar to that of Example 1 was prepared, but using 30% by weight of Ag nanoparticles instead of Ag flakes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com