Shaft diameter bidirectional conductivity controllable conductive polymer tube and preparation method thereof

A conductive polymer and polymer tube technology, which is applied in the field of axial-diameter bidirectional conductivity controllable conductive polymer tube and its preparation field, can solve the problem of a large amount of conductive filler added, and achieve high-quality competitive advantages, simple regulation, and permeability. The effect of a low threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

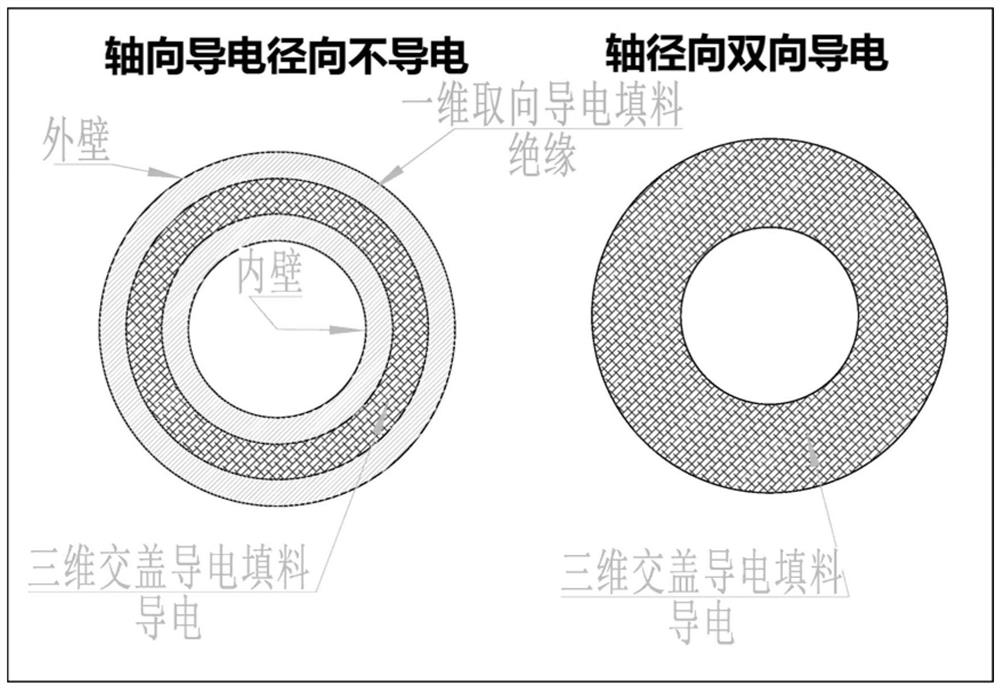

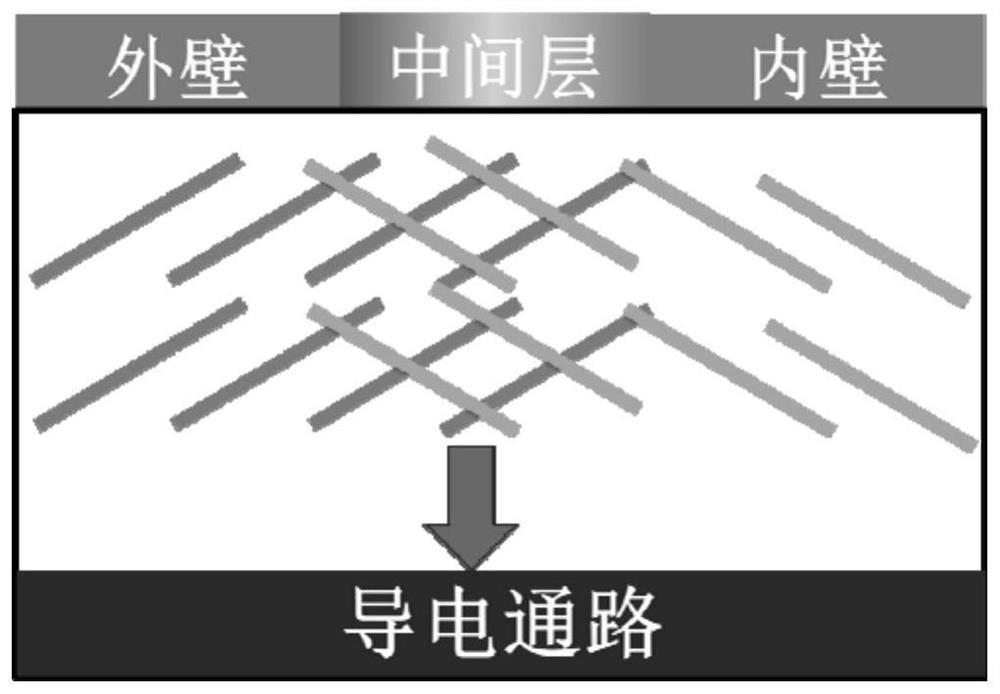

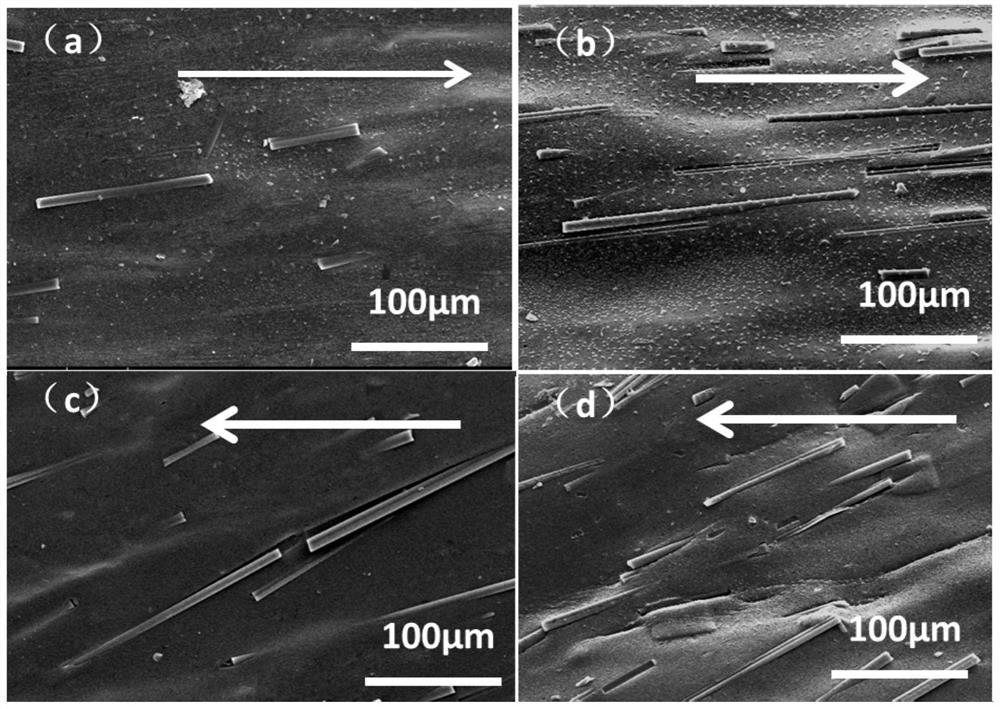

[0038] Therefore, the present invention provides a method for preparing a conductive polymer tube with controllable axial bidirectional conductivity, comprising the following steps: uniformly mixing 50-99.99 parts by weight of polymer with 0.01-50 parts by weight of conductive filler, and then mixing the mixture Put it in a polymer tube rotary extrusion device and carry out melt rotary extrusion at a speed of 1-60rpm / min, and the extruded tube blank can be cooled and sized under the traction of the tractor; the rotation is the relative The die rotates independently, the die rotates independently relative to the mandrel, the mandrel and the die rotate in the same direction at the same time, or the mandrel and the die rotate in opposite directions at the same time. Here, the polymer and the conductive filler can also be melt-extruded by a conventional method, pelletized, and put into a polymer tube rotary extrusion device.

[0039] Preferably, the rotation is reverse rotation of...

Embodiment 1

[0055] First, 99.99 parts by weight of polyethylene LDPE (brand: 2420H) and 0.01 parts by weight of carbon nanotubes are melt-extruded and pelletized in a twin-screw extruder, and then the obtained pellets are placed in a polymer tube rotary extrusion device. The mandrel is rotated independently, and the rotational speed of 10rpm / min is melted and rotated for extrusion, and the extruded tube blank is cooled and sized under the traction of the tractor to obtain a polymer tube with a diameter of ¢3.

[0056] The axial conductivity of the pipe obtained in this embodiment is 1.92×10 -3 S / cm, the radial conductivity is 1.5×10 -11 S / cm.

Embodiment 2

[0058] First, 99.9 parts by weight of polyethylene LDPE (brand: 2420H) and 0.1 parts by weight of graphene are melt-extruded and pelletized in a twin-screw extruder, and then the obtained pellets are placed in a polymer tube rotary extrusion device. The die is rotated separately, melted and rotated at a speed of 20 rpm / min, and the extruded tube blank is cooled and sized under the traction of a tractor to obtain a polymer tube with a diameter of ¢3.

[0059] The axial conductivity of the pipe obtained in this embodiment is 3.92×10 -2 S / cm, the radial conductivity is 4.2×10 -11 S / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com