Electrostrictive composite material and preparation method thereof

A composite material and stretching technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of uneven dispersion of carbon nanotubes 12, Carbon nanotubes 12 are prone to agglomeration and other problems, achieving the effects of large stress, low dielectric loss, and accelerated response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

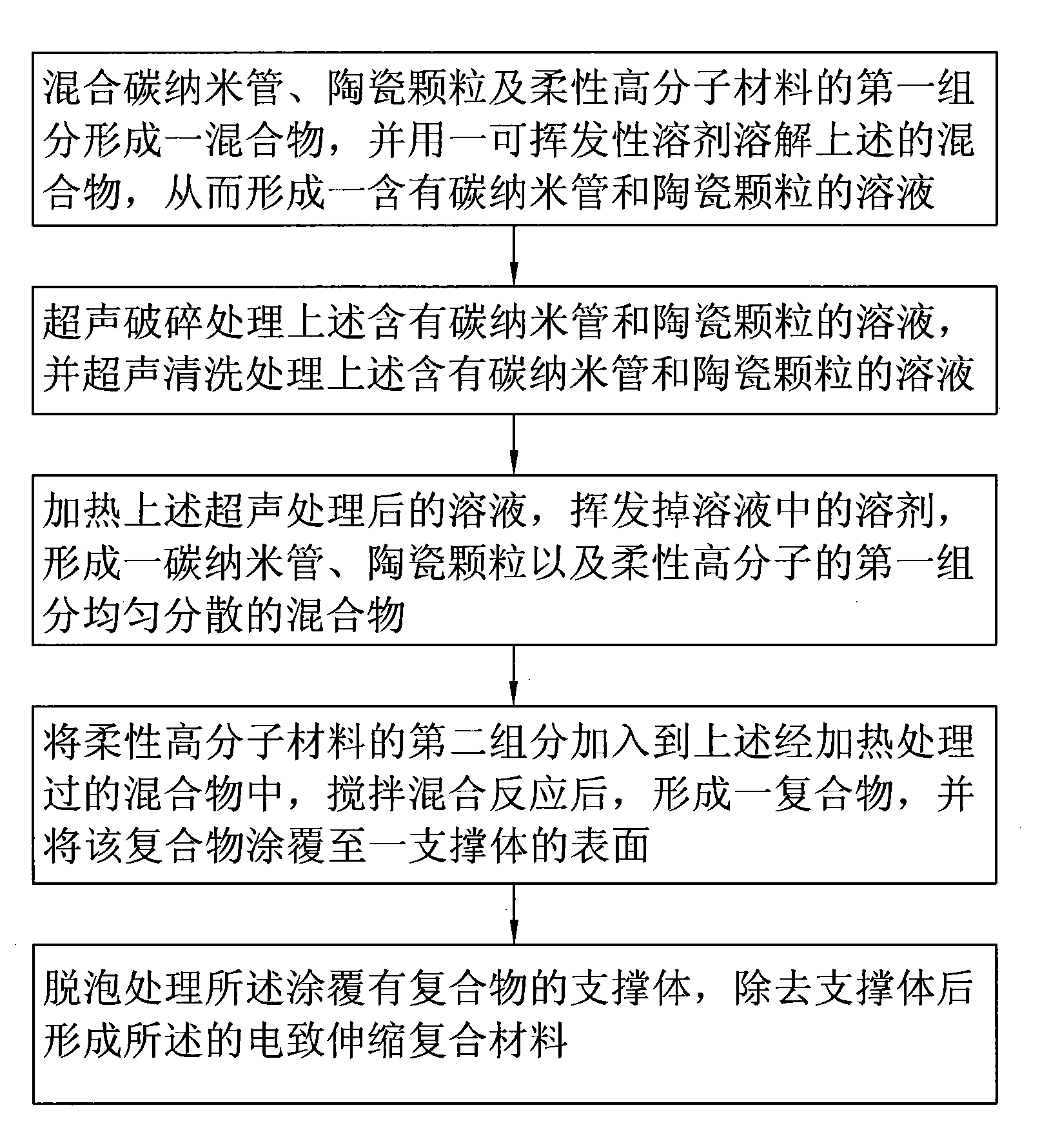

[0011] The electrostrictive composite material of the technical solution and its preparation method will be described in detail below in conjunction with the accompanying drawings.

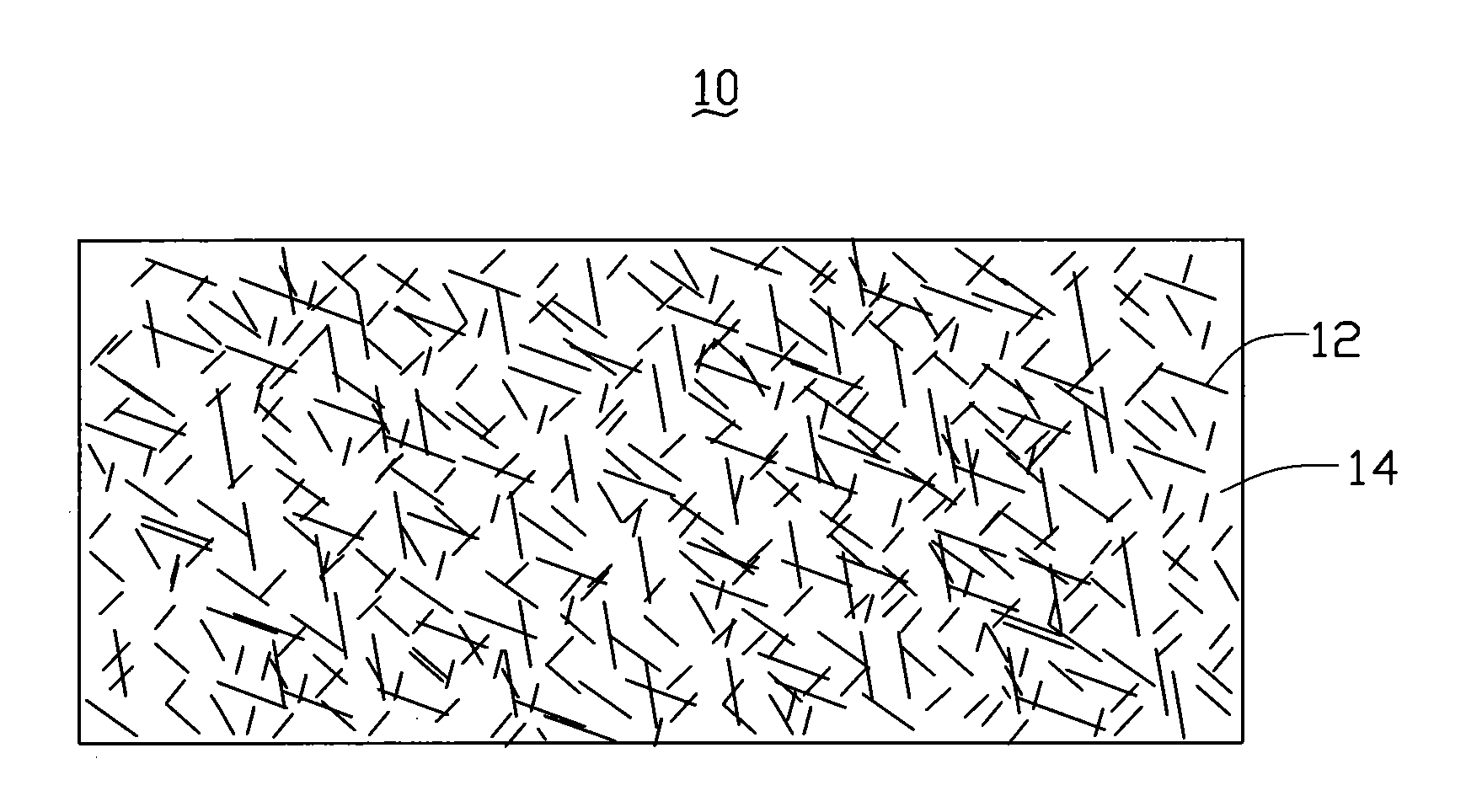

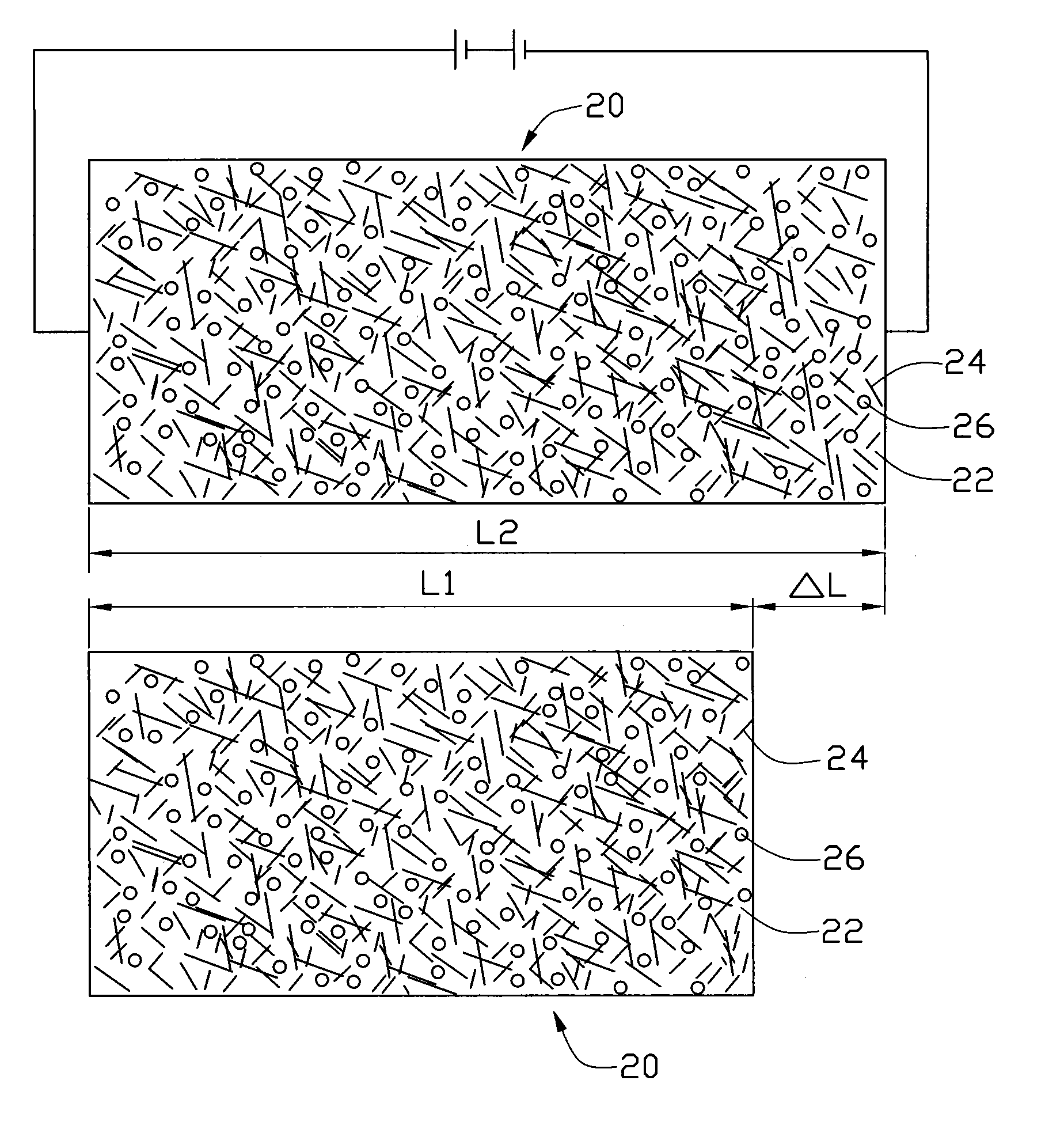

[0012] see figure 2 , an electrostrictive composite material 20 provided by the embodiment of the technical solution, which includes a flexible polymer substrate 22, a plurality of carbon nanotubes 24 uniformly dispersed in the flexible polymer substrate, and uniformly dispersed in the A plurality of ceramic particles 26 in the flexible polymeric substrate 22 . The carbon nanotubes 24 are evenly distributed in the silicone rubber substrate, and the carbon nanotubes 24 overlap each other to form a large number of conductive networks in the flexible polymer substrate 22 . The flexible polymer substrate 20 can be selected from one of silicone rubber elastomers, polyurethane, epoxy resin, polymethyl methacrylate and any combination thereof. The ceramic particles 26 may be selected from one of alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com