Self alignment contact scheme, semiconductor device and method for manufacturing the same

A semiconductor, conductive contact technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as short circuit of conductive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

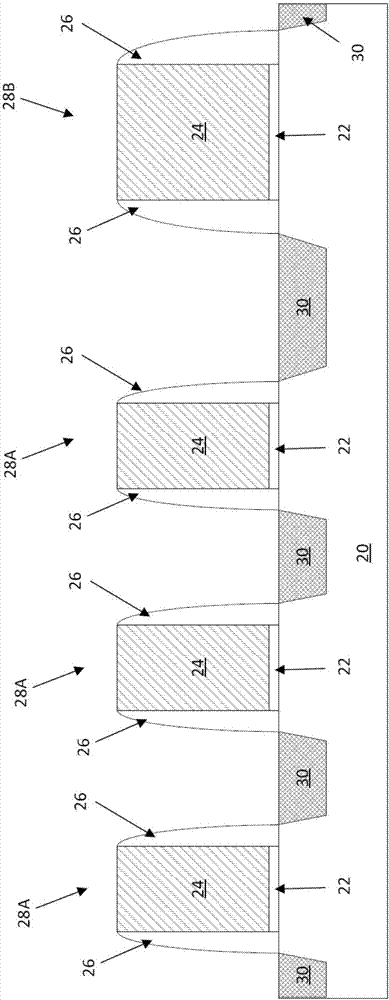

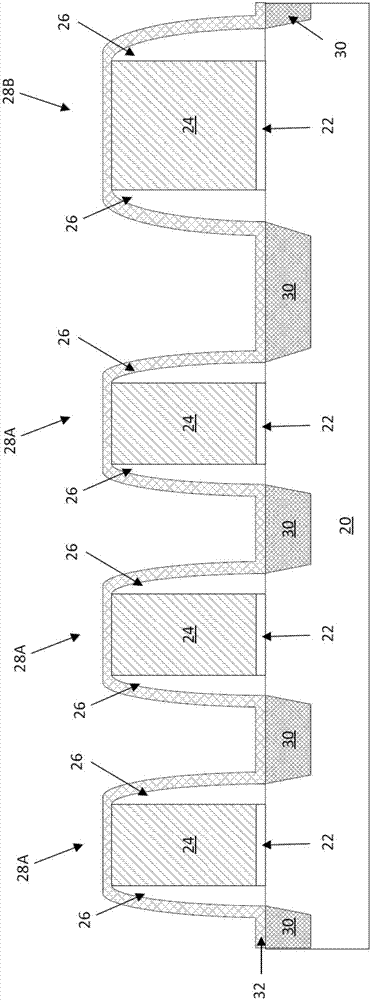

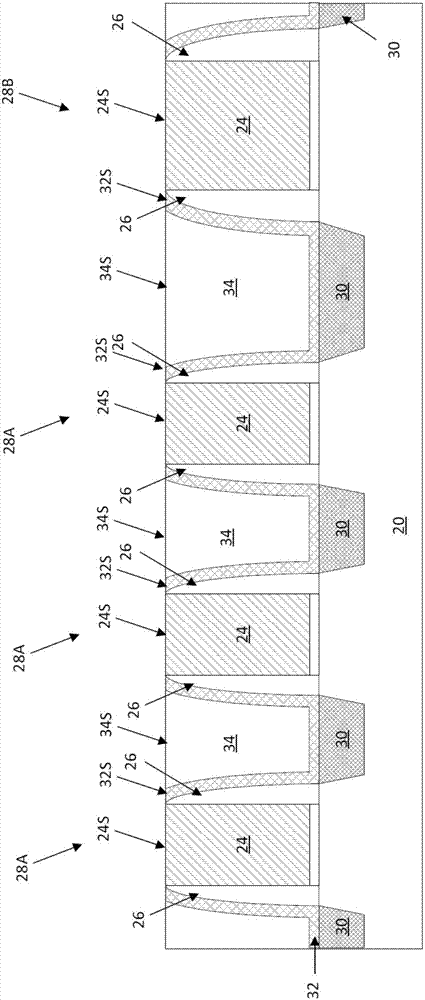

[0059] An embodiment is a method including: forming a first gate over a substrate, the first gate having first gate spacers on opposite sidewalls of the first gate; and forming a first gate over the first gate A hard mask layer; a second hard mask layer is formed above the first hard mask layer, the second hard mask layer has a different material composition from the first hard mask layer; adjacent to the first gate and in the A first dielectric layer is formed above a gate; a first opening through the first dielectric layer is etched to expose a portion of the substrate, and at least a portion of the second hard mask layer is exposed in the first opening; and a conductive material is used to fill A first opening; and removing the second hard mask layer and removing the conductive material and the portion of the first dielectric layer located above the first hard mask layer to form a first conductive contact in the remaining first dielectric layer.

[0060] In an embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com